Shape memory polymer-based air filling extensible wing and methods for manufacturing same

A technology of memory polymer and production method, which is applied in the direction of wings, wing adjustments, aircraft parts, etc., can solve the problems of unsatisfactory flight strength and stiffness, wing damage and air leakage, etc., and achieve high deployment reliability and material Effect of light weight, improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

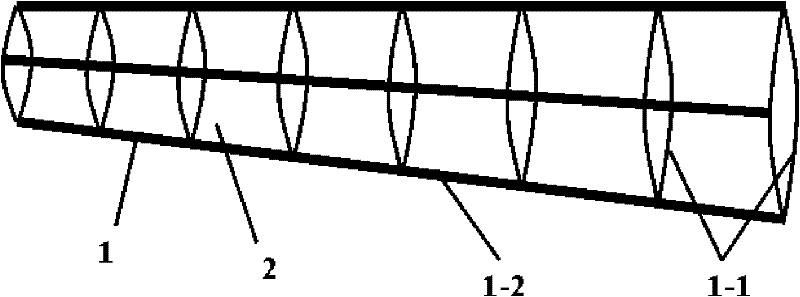

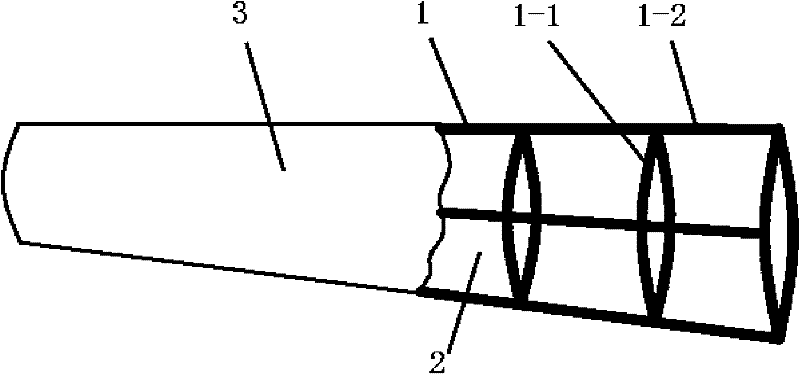

[0028] Specific implementation manner one: such as figure 1 with 2 As shown, the shape-memory polymer-based inflatable and deployable wing described in this embodiment is composed of a wing frame 1, a closed inflatable airbag 2 and a flexible skin 3. The closed inflatable airbag 2 is arranged in the frame 1, and the flexible skin 3 is coated on the outer surface of the skeleton 1, and the wing skeleton 1 is made of shape memory polymer.

[0029] The inflatable airbag 2 can be formed by connecting multiple independent unit inflatable airbags (that is, the closed inflatable airbag 2 inside the wing skeleton 1 is connected by a number of airbags, which provide internal pressure for the deployed wing after inflation), and the adjacent two wings The space between the ribs forms a cavity inside the wing for placing the unit inflatable airbag. In addition, skins are placed on the upper and lower surfaces of the wing and fixed, and flexible skins are placed on the outside of the wing to ...

specific Embodiment approach 2

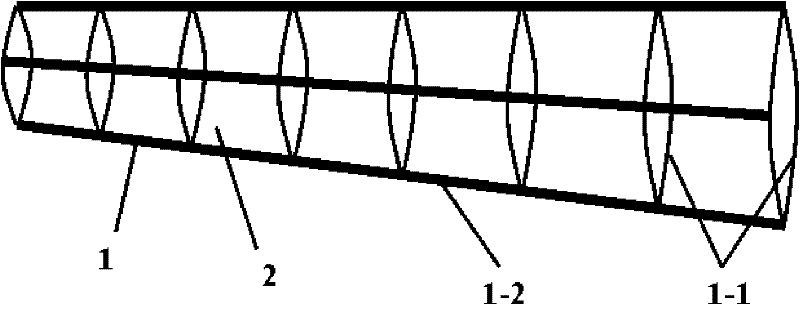

[0031] Specific implementation manner two: such as figure 1 with 2 As shown, the wing skeleton 1 of this embodiment is composed of a plurality of wing ribs 1-1 and a plurality of wing spars 1-2. The multiple wing ribs 1-1 are a set of wings whose geometric shapes gradually become larger. The rib 1-1 is any shape in the NACA wing series. Multiple spars 1-2 and multiple wing ribs 1-1 are interlaced and fixed together to form a cylindrical net shape. skeleton. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation manner three: such as figure 1 with 2 As shown, in this embodiment, the number of the plurality of wing ribs 1-1 is eight, and the number of the plurality of wing spars 1-2 is four. Other components and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com