Flexible bamboo-formwork ecological and energy-saving wall and manufacturing method

A processing method and wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of being unable to be used as load-bearing walls, and achieve the effects of good modeling effect, cost reduction, and energy consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

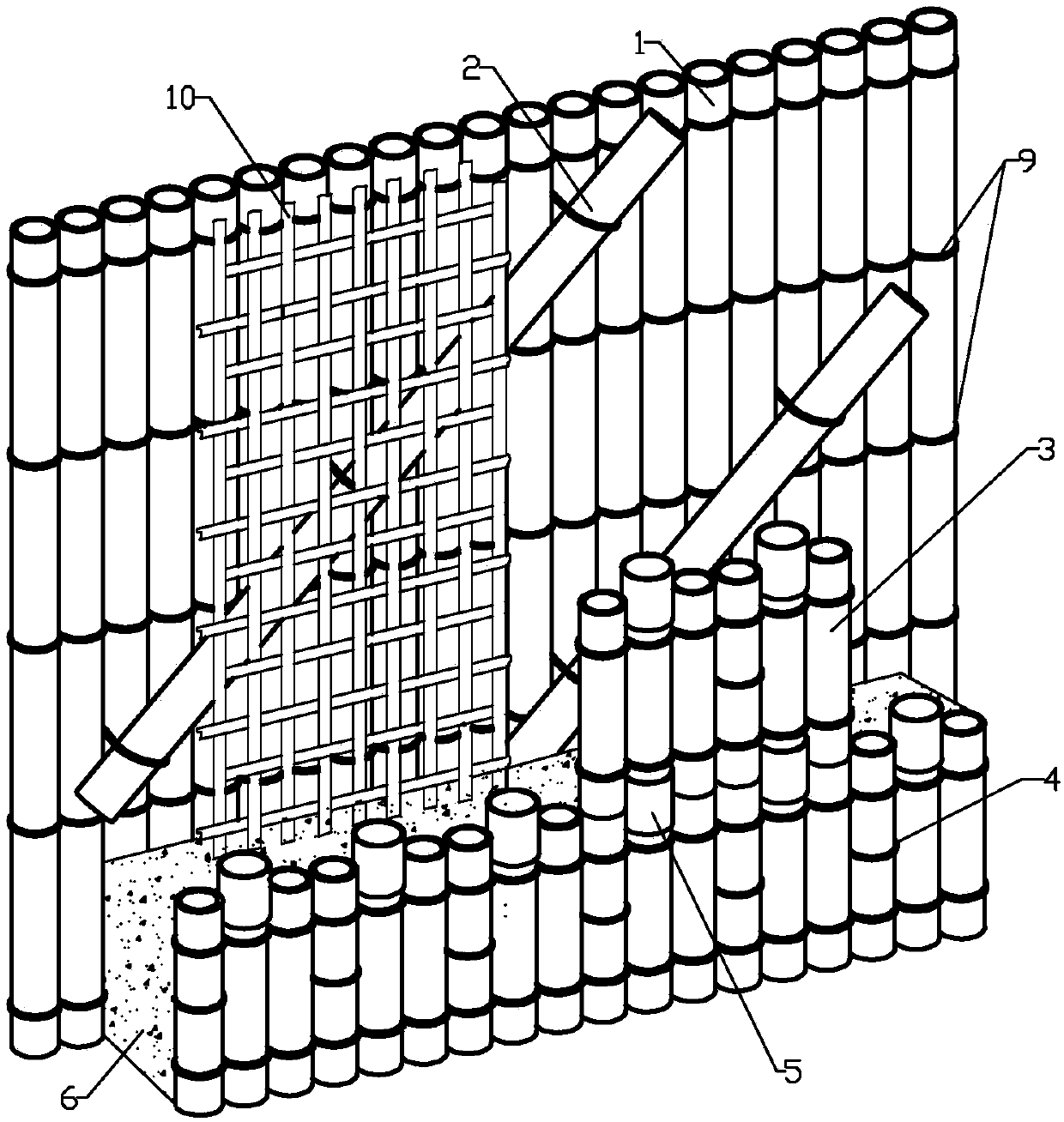

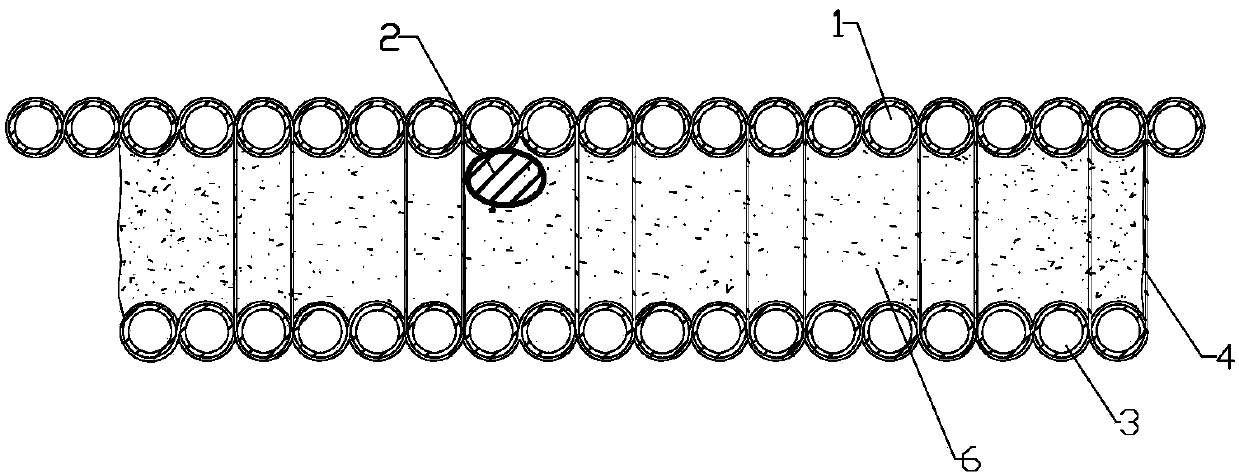

[0035] Such as figure 1 As shown, a flexible bamboo mold ecological energy-saving wall includes an outer bamboo mold 1 and an inner bamboo mold 12, and the outer bamboo mold 1 and the inner bamboo mold 12 are connected by steel bars 11 or lead wires 4 and filled with filling materials 6, Filling material 6 includes raw soil straw mixture and modified soil. Bamboo tendons 10 are vertically inserted in the filling material 6, and the bamboo tendons 10 are woven from a number of horizontally and vertically interlaced or woven bamboo strips.

[0036] to combine figure 2 As shown, the outer bamboo mold 1 is a bamboo raft 3 made by using lead wires 4 or steel wires interlaced to bind and connect several vertical bamboo poles with similar thicknesses in a row. Two parallel outer oblique bamboo braces 2 are fixed on the inner facade of the outer bamboo mold 1 . The outer inclined bamboo brace 2 is used to maintain the shape of the outer bamboo mold 1 and can strengthen the strengt...

Embodiment 2

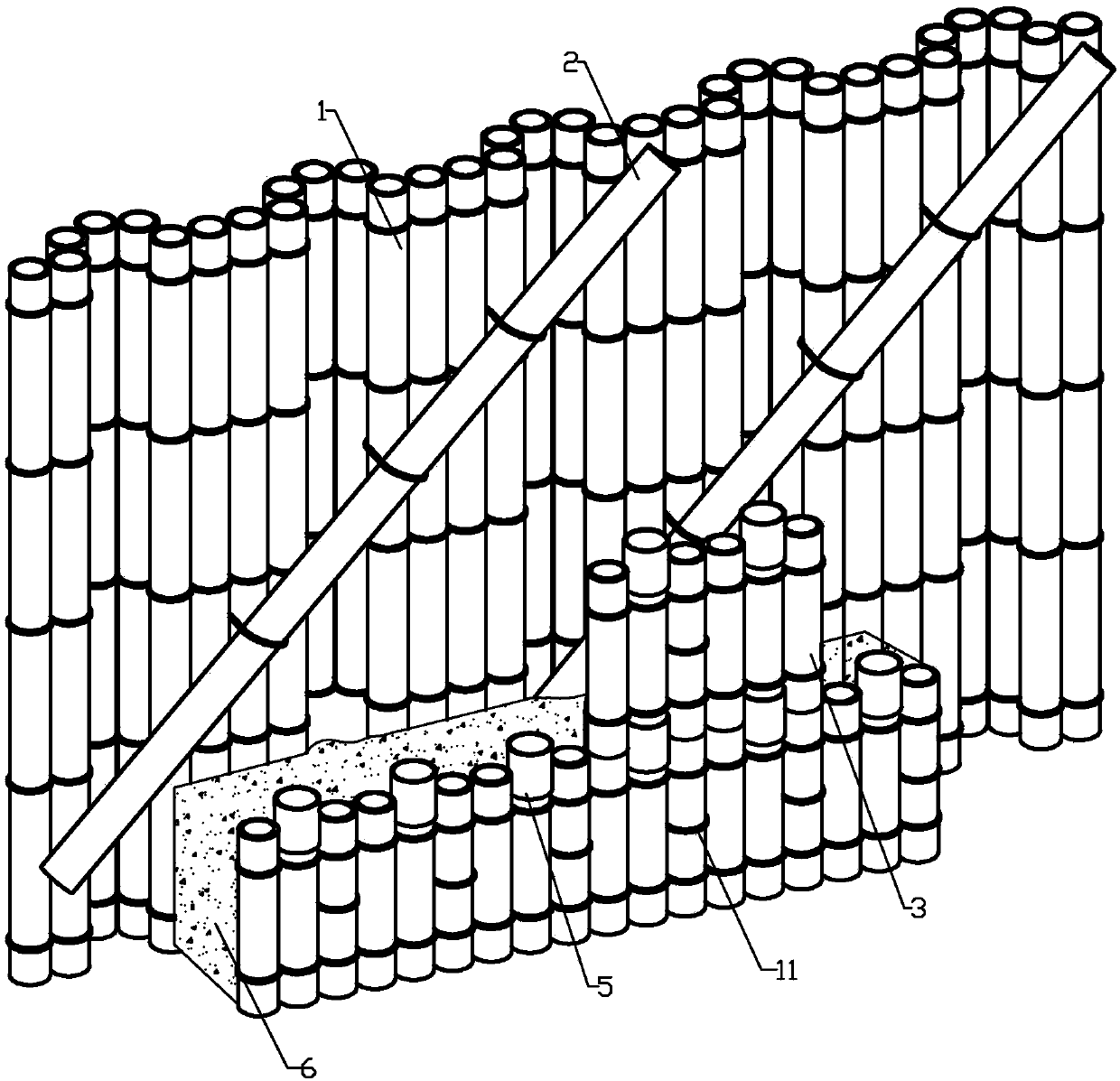

[0046] Such as image 3 As shown, a kind of flexible bamboo mold ecological energy-saving wall, including outer bamboo mold 1, inner bamboo mold 12, outer bamboo mold 1 and inner bamboo mold 12 are connected by steel bar 11, outer bamboo mold 1 and inner bamboo mold 12 The filling material 6 is filled between them, and the filling material 6 is modified soil.

[0047] combine Figure 4 As shown, the outer bamboo mold 1 is a wavy bamboo raft 3 made by intertwining and connecting several vertical bamboo poles with similar thicknesses using lead wires 4 or soft cables 9 . The outer bamboo mold 1 is fixed with an outer oblique bamboo brace 2 on the inner facade. Outer oblique bamboo support 2 and the bamboo pole of part outer bamboo mold 1, inner bamboo mold 12 are fixed by soft cable 9. The inner bamboo mold 12 is still a smooth plate shape, and is formed by stacking bamboo rafts 3 with the same size by the staggered seam method. The bamboo raft 3 is formed by connecting side...

Embodiment 3

[0057] Such as Figure 7 As shown, a flexible bamboo mold ecological energy-saving wall, comprising an outer bamboo mold 1, an inner bamboo mold 12, the outer bamboo mold 1 and the inner bamboo mold 12 are connected by lead wire 4, and the outer bamboo mold 1 and the inner bamboo mold 12 The spaces are filled with foamed concrete (not shown). The outer bamboo mold 1 is a wavy bamboo raft 3 formed by intertwining and connecting several vertical bamboo poles with similar thicknesses using lead wires 4 . The outer bamboo mold 1 and the inner bamboo mold 12 are respectively fixed with an outer oblique bamboo brace 2 and an inner oblique bamboo brace 13 on the inner facade. Outer oblique bamboo support 2 and outer bamboo mold 1, inner oblique bamboo support 13 and the part bamboo pole of inner bamboo mold 12 are fixed by lead wire 4 or soft cable 9. The inner bamboo mold 12 is stacked by a number of bamboo rafts 3 of the same size using a staggered seam method. The bamboo raft 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com