DPF cylinder assembly sealing structure

A cylinder component and sealing structure technology, which is applied in the direction of engine sealing, engine components, noise reduction devices, etc., can solve problems such as poor machining performance, large thickness of V-shaped sealing ring, and large air leakage at the clamp lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

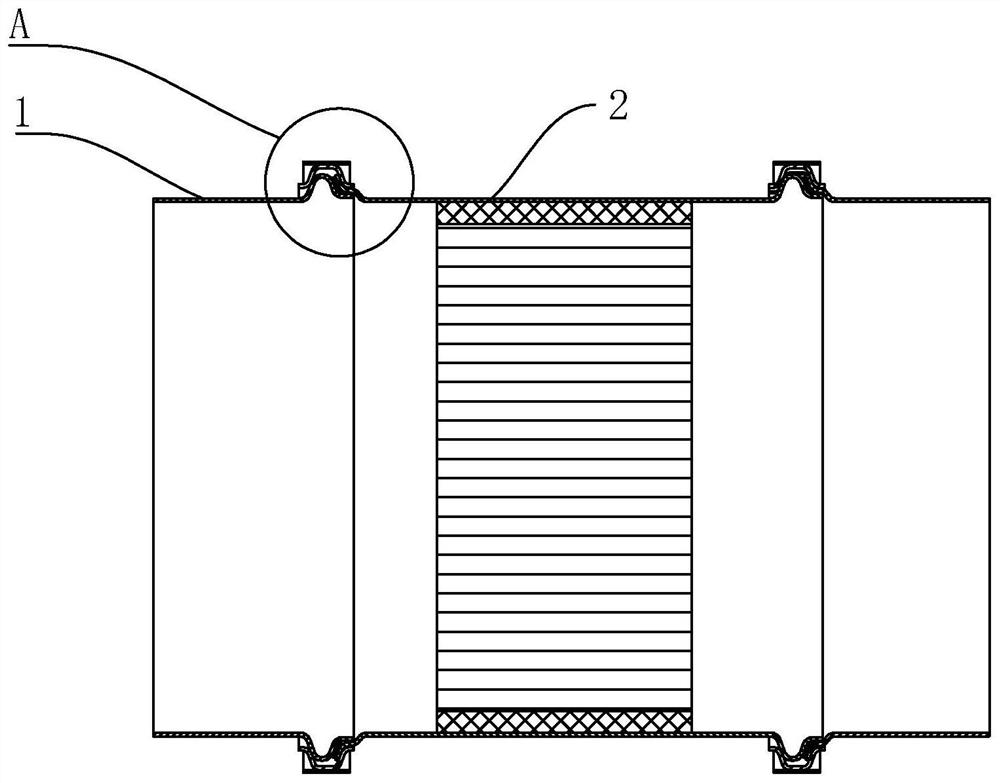

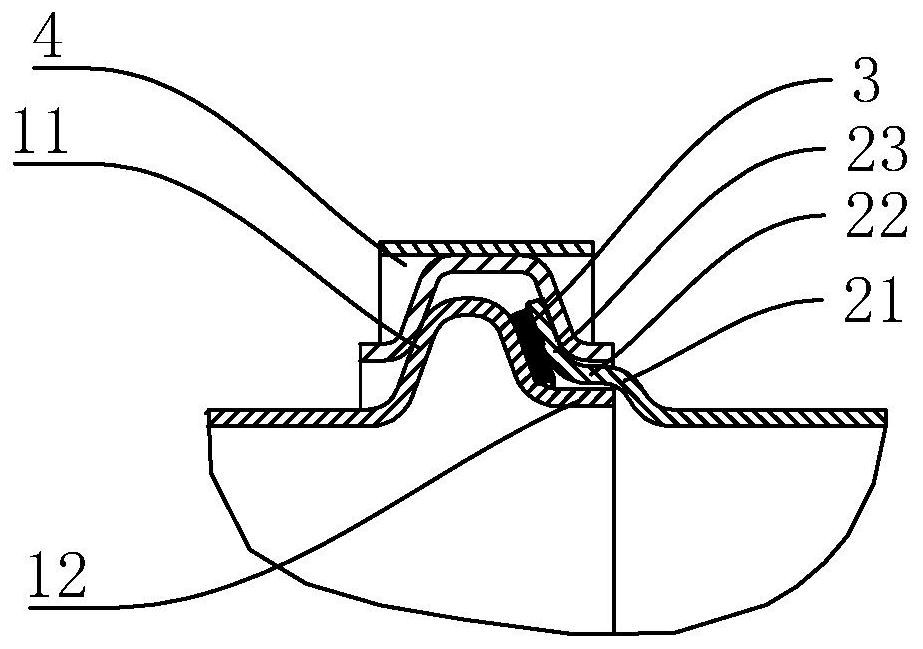

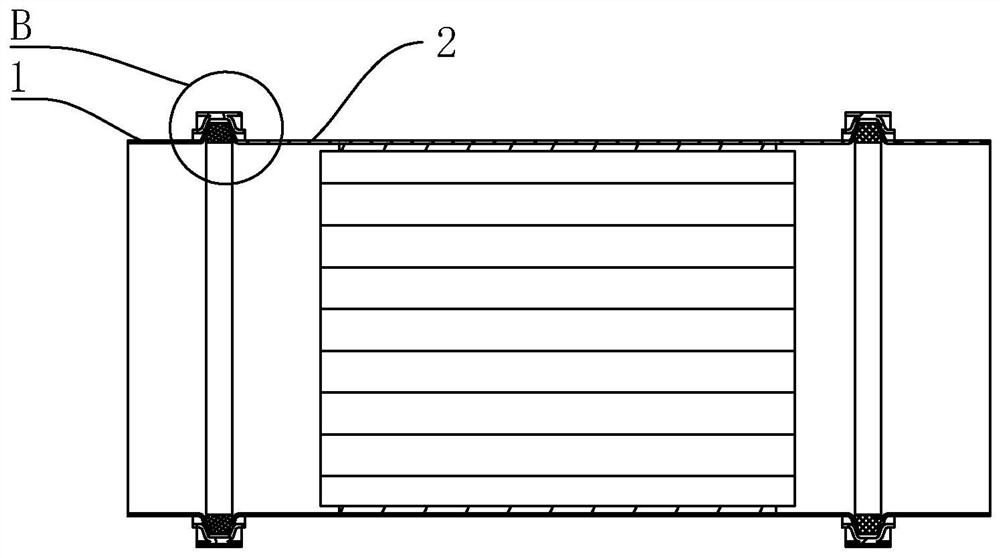

[0025] Such as Figure 1-4 It can be seen that the present invention includes: a front cylinder body 1, a DPF cylinder body 2, a sealing ring 3 and a V-shaped hoop 4, and the side of the front cylinder body 1 and the DPF cylinder body 2 is positioned axially and radially To cooperate, the side of the front cylinder 1 close to the DPF cylinder 2 is arc-shaped with straight sides, and a sealing ring 3 is interposed between the front cylinder 1 and the DPF cylinder 2, and the front cylinder 1 1 and the DPF cylinder body 2 are sealed together by a V-shaped hoop 4 .

[0026] In use, the arc-shaped front cylinder body 1 flange is matched with the DPF cylinder body 2, which reduces one fit in the original technology and reduces air leakage points; in addition, the front cylinder body 1 with straight sides and the DPF cylinder body 2 The left end is used for axial positioning and radial fit, and a fit is added before the air leakage point, which greatly reduces the air leakage rate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com