Refractory sealing material for coke oven end

A sealing material and furnace head technology, which is applied in the field of refractory materials for coke ovens, can solve the problems of easy oxidation, unsuitable for coke oven furnace head sealing, etc., and achieve the effects of easy application, improved coke oven production environment, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

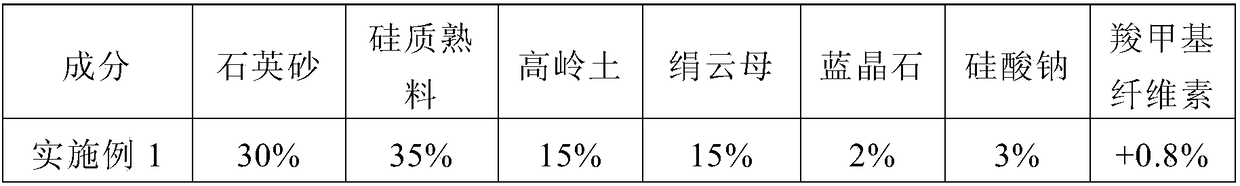

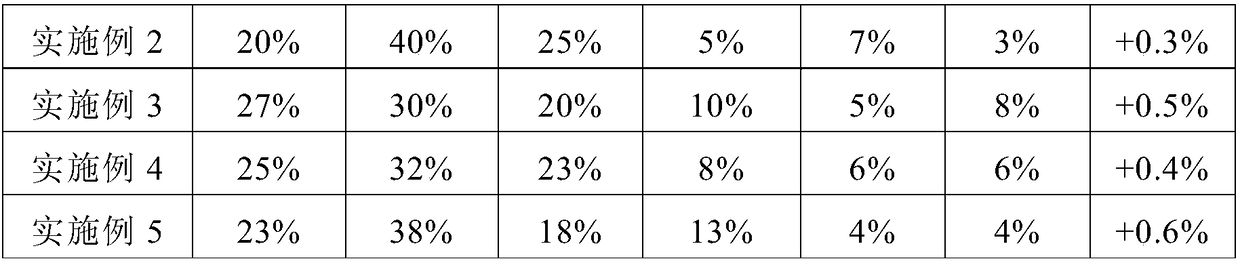

[0027] The embodiment of the present invention stirs according to the composition of Table 1, adds water 22% and stirs into mud material, adopts the method for mechanical or manual smearing, fills in the position that needs sealing of coke oven burner head.

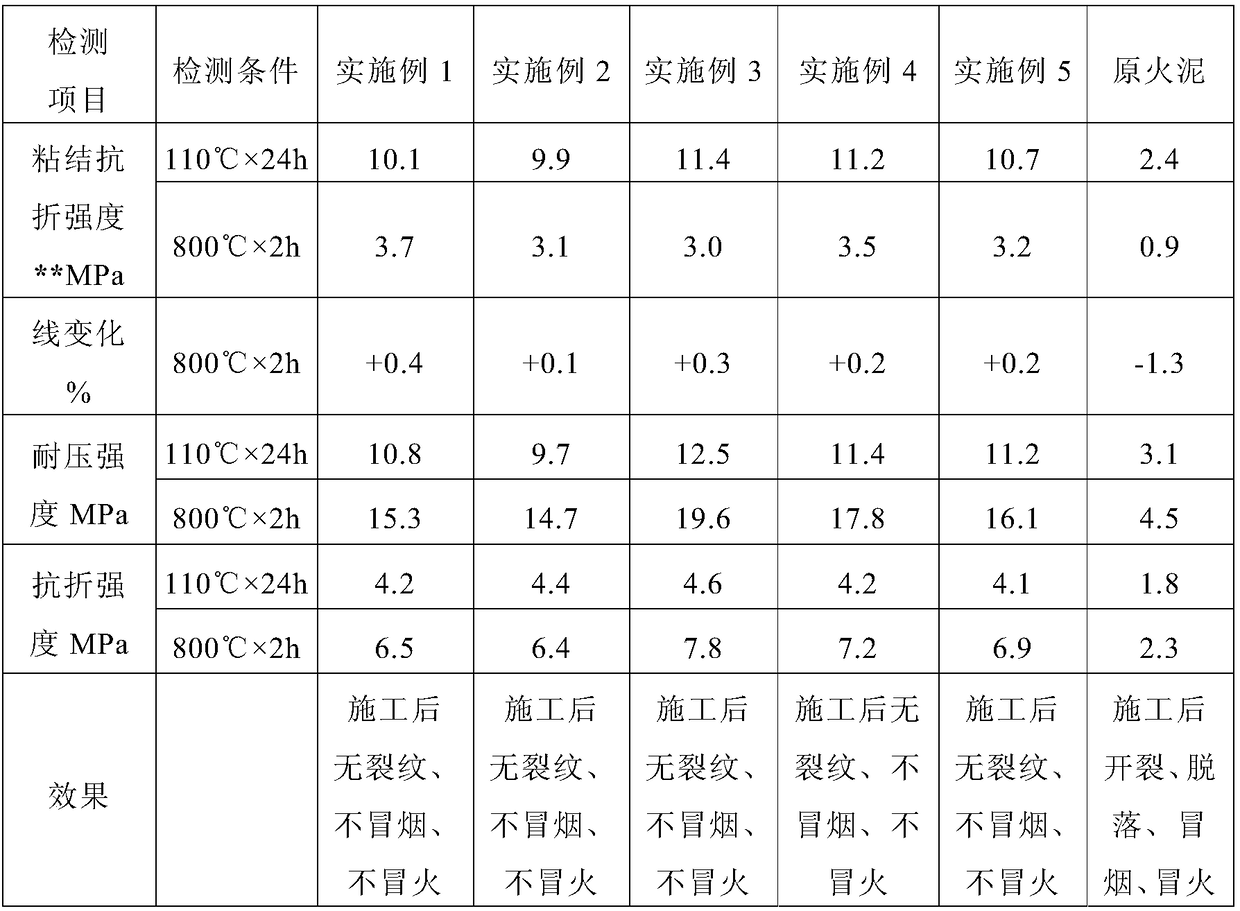

[0028] Table 2 is the physical performance technical index of the embodiment of the present invention.

[0029] Table 1

[0030]

[0031]

[0032] Table 2

[0033]

[0034] ** Bonding flexural strength is the strength measured when the sealant is bonded to refractory bricks and metal iron blocks at the same time, and the higher the value, the better.

[0035] As can be seen from Table 2, the refractory sealing material for the coke oven head of the present invention has good strength, and can withstand long-term air flow erosion; the bonding strength with iron parts and refractory bricks is high, and the high temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com