Feeding method and equipment of anode refining furnace

A feeding method and feeding equipment technology, applied in the field of anode refining furnaces, can solve problems such as unfavorable flue gas waste heat recovery and flue gas treatment, lower flue gas temperature, complex structure, etc., and achieve favorable flue gas waste heat recovery and follow-up flue gas treatment, small amount of flue gas, and good airtightness of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

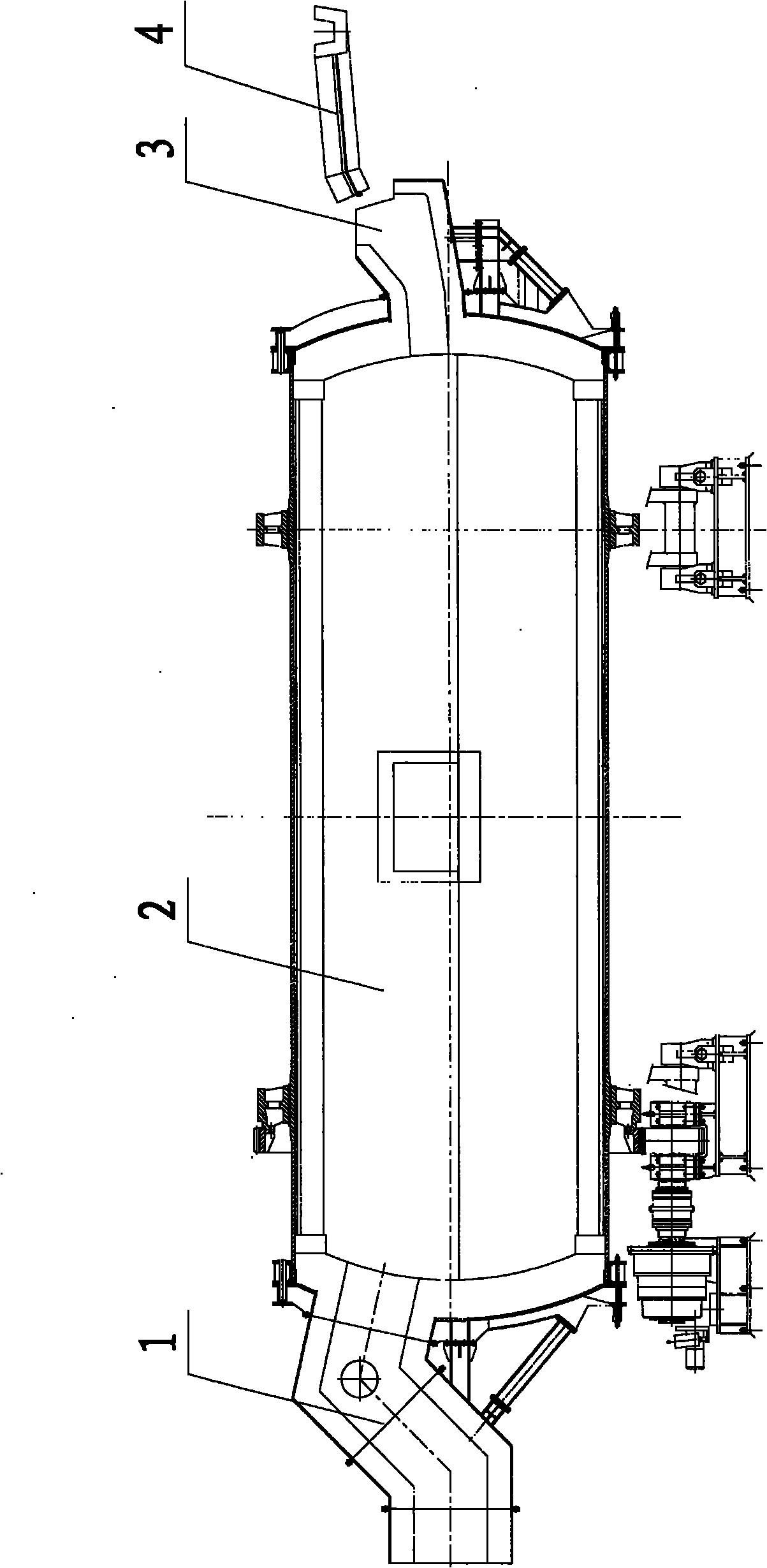

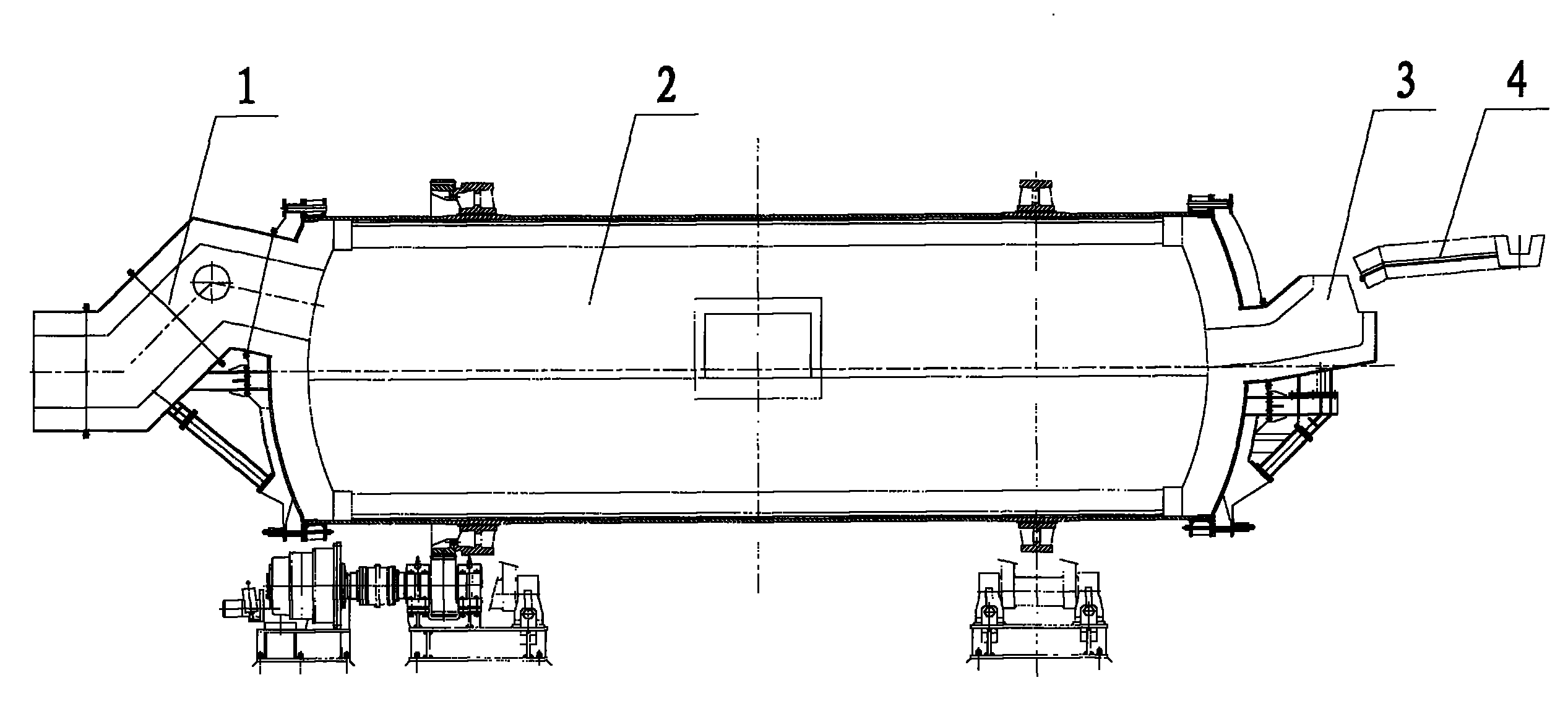

[0028] A feeding device for an anode refining furnace using a continuous copper blowing process, comprising a feeding port 3 of an anode refining furnace 2, a smoke exhaust port 1, and a connecting chute 4 arranged between the anode refining furnace and the blowing furnace. The height difference between the feed opening 3 and the copper opening of the blowing furnace is 2m, and it is connected with the connecting chute 4 .

[0029] The feeding port 3 is welded by steel plate, lined with refractory material, and fixed on the upper end wall of the anode refining furnace 2 with a bracket. One end wall, the feeding port 3 tilts along with the anode refining furnace 2. The smoke outlet 1 is directly connected to the inlet of the subsequent flue gas treatment system. The subsequent flue gas treatment system is a waste heat recovery boiler.

[0030] The feeding method of this specific embodiment one equipment is:

[0031] The hot blister copper blown by the converting furnace is d...

specific Embodiment approach 2

[0032] It is basically the same as Embodiment 1, except that the flue gas generated during the refining process is discharged from the exhaust port 1 of the side wall at the other end of the anode refining furnace 2, and enters the spray cooler for subsequent flue gas treatment.

specific Embodiment approach 3

[0033] It is basically the same as Embodiment 1, except that the flue gas generated during the refining process is discharged from the exhaust port 1 of the side wall at the other end of the anode refining furnace 2, and enters the secondary combustion chamber to be cooled by cold air for subsequent flue gas treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com