Flange sealing device

A flange sealing and sealing ring technology, used in flange connection, pipe/pipe joint/pipe fittings, through components, etc., can solve the problems of material loss in the pipeline, loss of sealing effect, pollution of the factory building, etc., to improve the flange surface , Simple structure, flexible and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

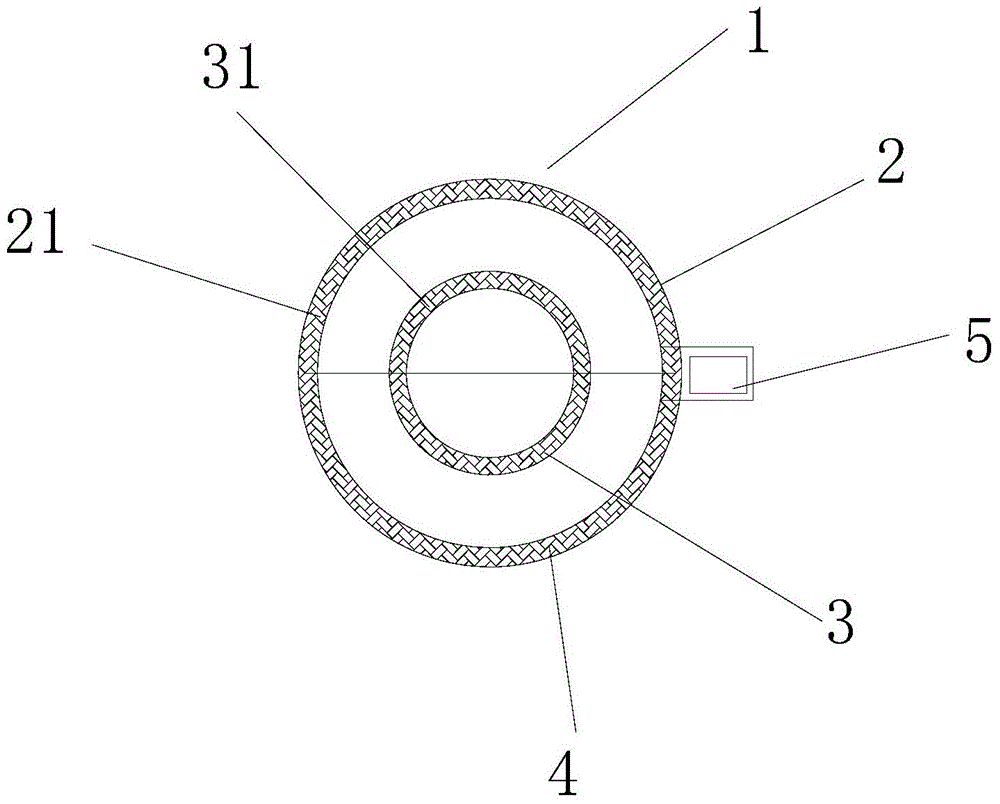

[0012] A flange sealing device, comprising a connecting flange body 1, the surface of the connecting flange is provided with an epoxy primer coating, the butt joints of the connecting flanges are connected by glue injection, and the connecting flange body 1 It has an outer ring 2 and an inner ring 3, the outer ring 2 is provided with an outer ring sealing groove 21, the inner ring 3 is provided with an inner ring sealing groove 31, the outer ring sealing groove 21 and the inner ring sealing groove 31 are inlaid with matching sealing rings 4, and the edge of the connecting flange is provided with an adjusting handwheel 5, the adjusting handwheel 5 is connected with the threaded connector, and the sealing ring 4 is made of corrosion-resistant materials or ordinary rubber constitute.

[0013] The structure of the invention is simple. Compared with the prior art, the flange surface is coated with epoxy primer to improve the flange surface. At the same time, glue is injected and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com