Foaming and filling type tire and manufacturing method thereof

A technology of foam filling and manufacturing methods, which is applied in the direction of non-pneumatic tires, vehicle parts, tire parts, etc., can solve the problems of unsafe regeneration, achieve stable tire pressure, improve tire life, and facilitate tire replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

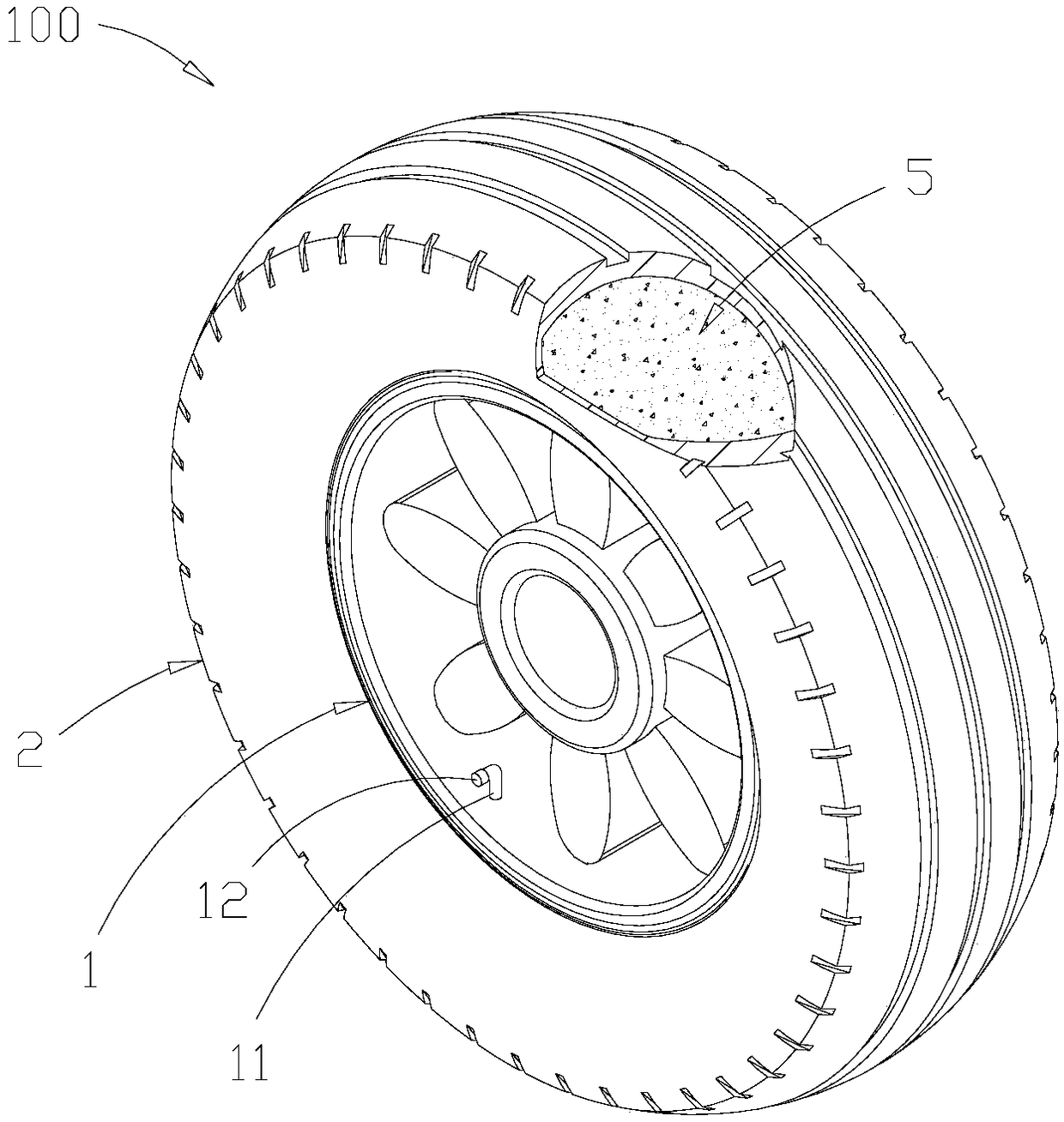

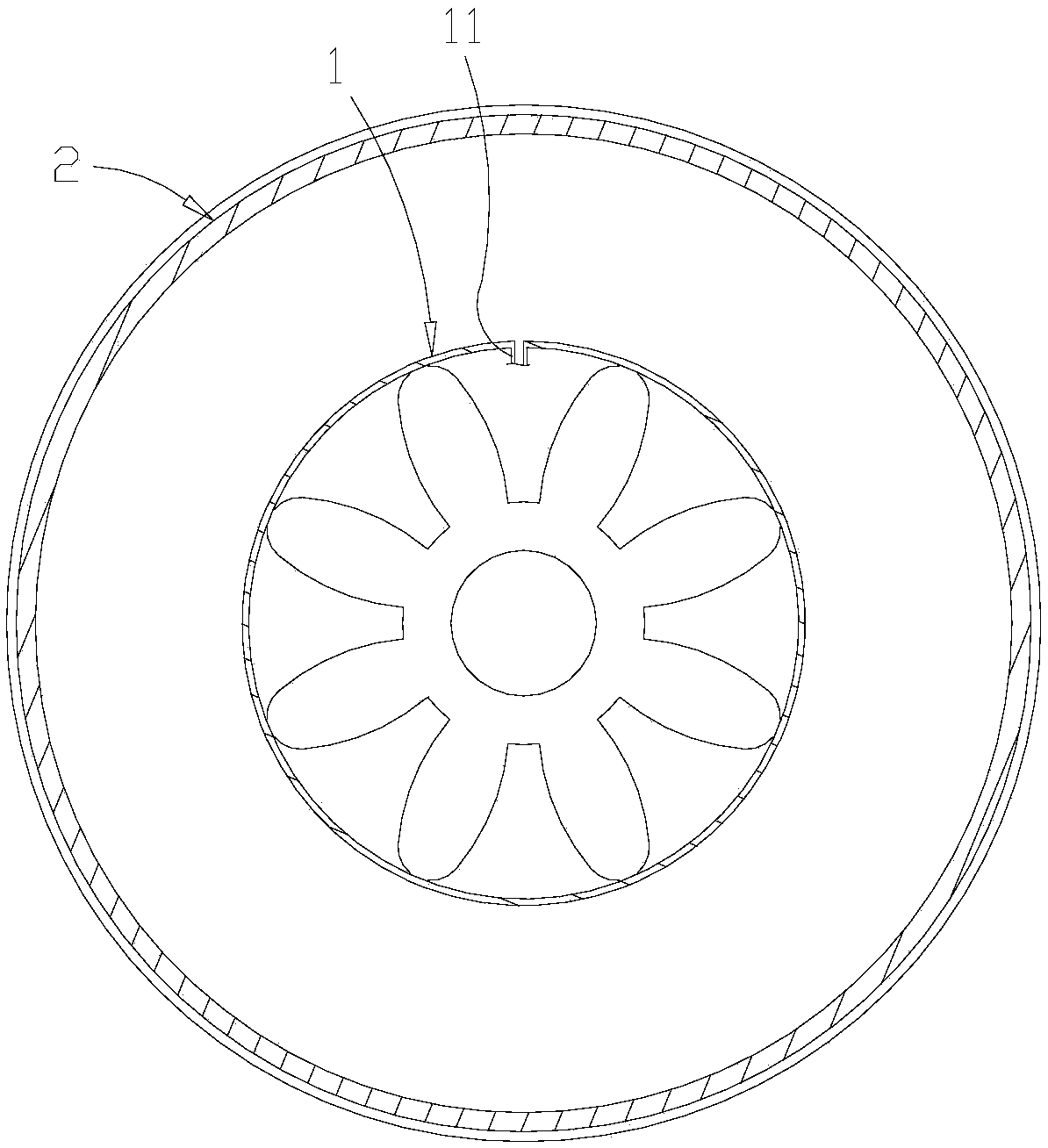

[0041] Such as figure 1 As shown, the foam-filled wheel 100 of the present invention includes: a steel rim 1 connected to the power device of the vehicle (not shown in the figure), the inner edge has a filling port 11, and a filling port check valve 12; a tire 2. Set at the outer edge of the steel ring 1; and a filling material 5, which is filled between the steel ring 1 and the tire 2 through the filling port 11 of the steel ring 1; the filling material 5 is a foamed material, which is made of The filling port 11 of 1 is filled between the steel rim 1 and the tire 2, and it will not leak when the tire is damaged. It can continue to support the vehicle so that the tire can neither leak nor blow, and can continue when the tire is damaged. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com