Steering load-bearing axle

A heavy-axle, horizontal technology, applied to fluid steering mechanisms, axles, wheels, etc., can solve problems such as lack of steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

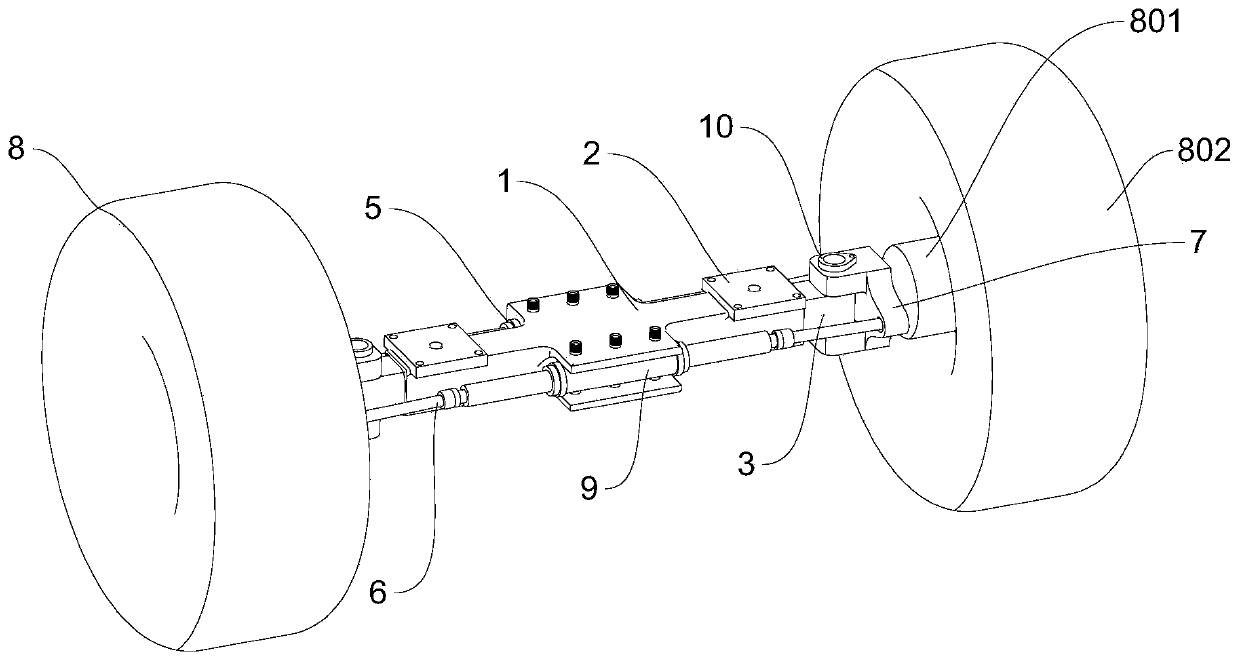

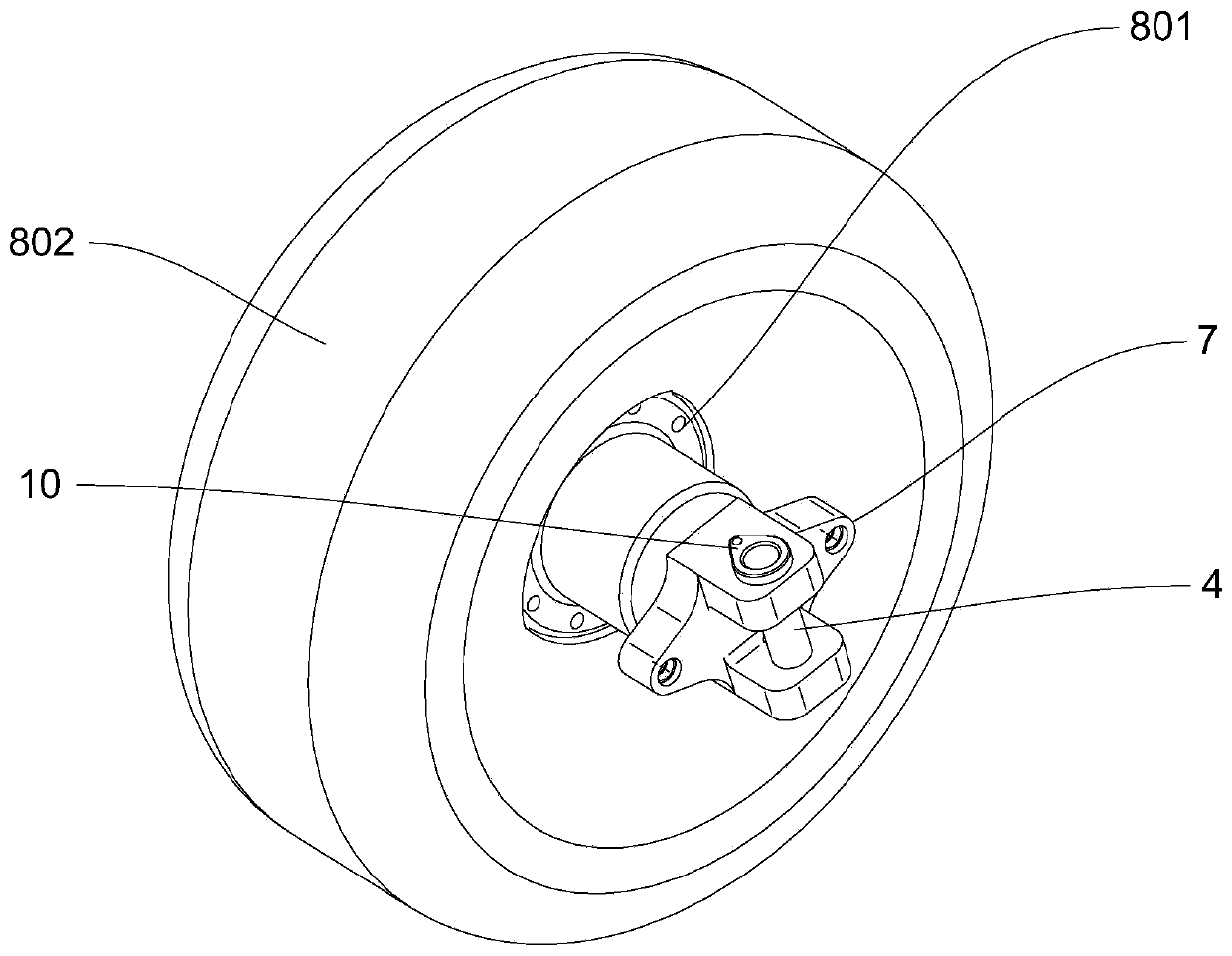

[0033] Please refer to Figure 1-Figure 5 , This embodiment provides a steering load-bearing axle, which solves the problem that the existing self-steering load-bearing axle does not have steering when driving in the opposite direction.

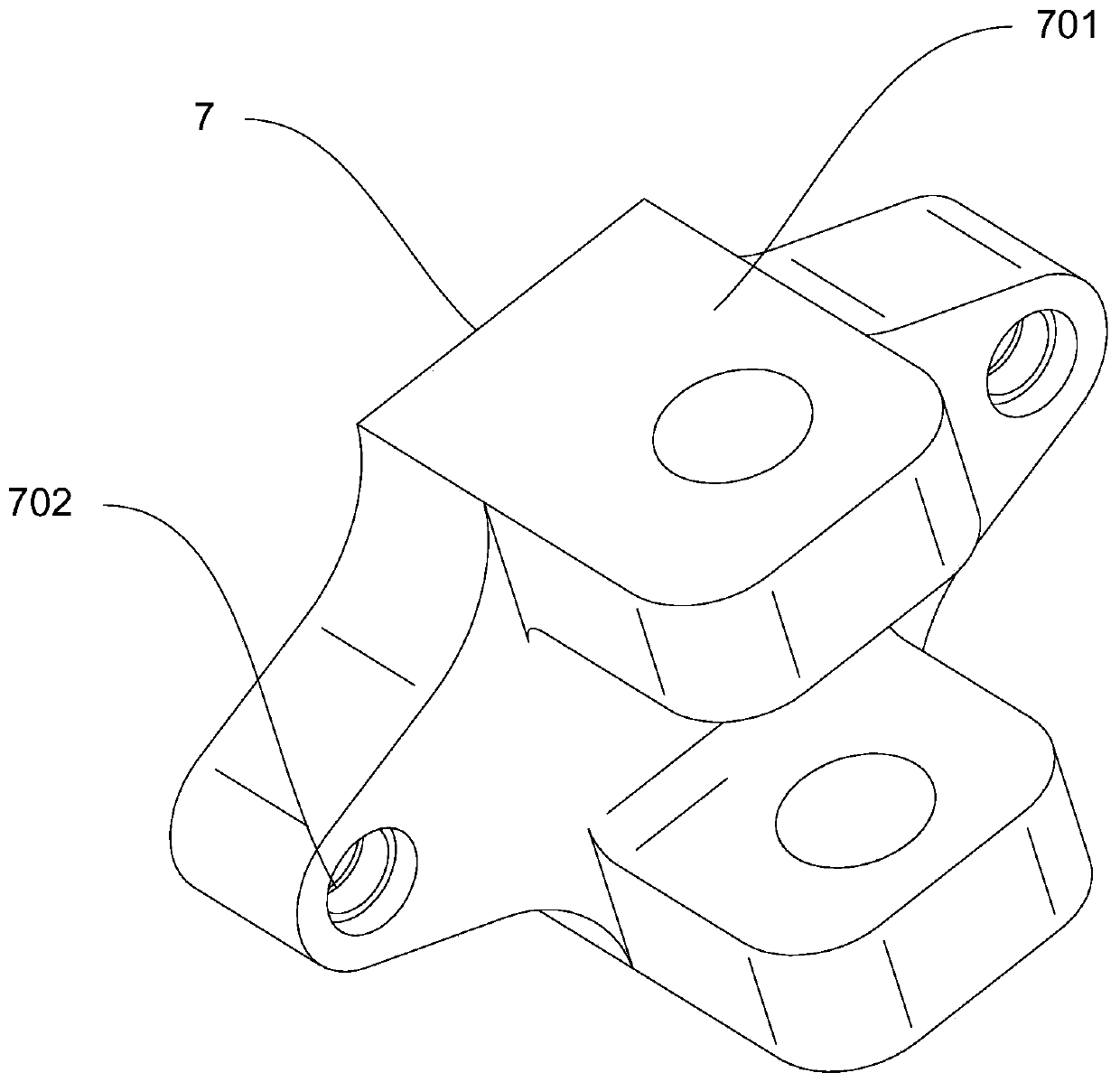

[0034] A steering load-bearing axle, including a main beam 3 placed horizontally, a sliding beam 1 that can slide along its axis is sleeved on the main beam 3, and load-bearing trays 2 are provided at both ends of the upper side of the sliding beam 1, The front side of the above-mentioned sliding beam 1 is provided with a front double-outlet rod type steering centering hydraulic cylinder 9 along its axial direction, and the rear side of the above-mentioned sliding beam 1 is provided with a rear double-outlet rod type steering centering hydraulic cylinder along its axial direction. 5. Connecting rods 6 are provided on both sides of the above-mentioned front double-rod steering centering hydraulic cylinder 9 and both sides of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com