Extra-large type geotechnical centrifuge loading separable design

A geotechnical centrifuge and super-large technology, applied in the direction of centrifuges, etc., can solve the problems of inconvenient use and safety risks, and achieve the effect of reducing the maximum power and saving the cost of development and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

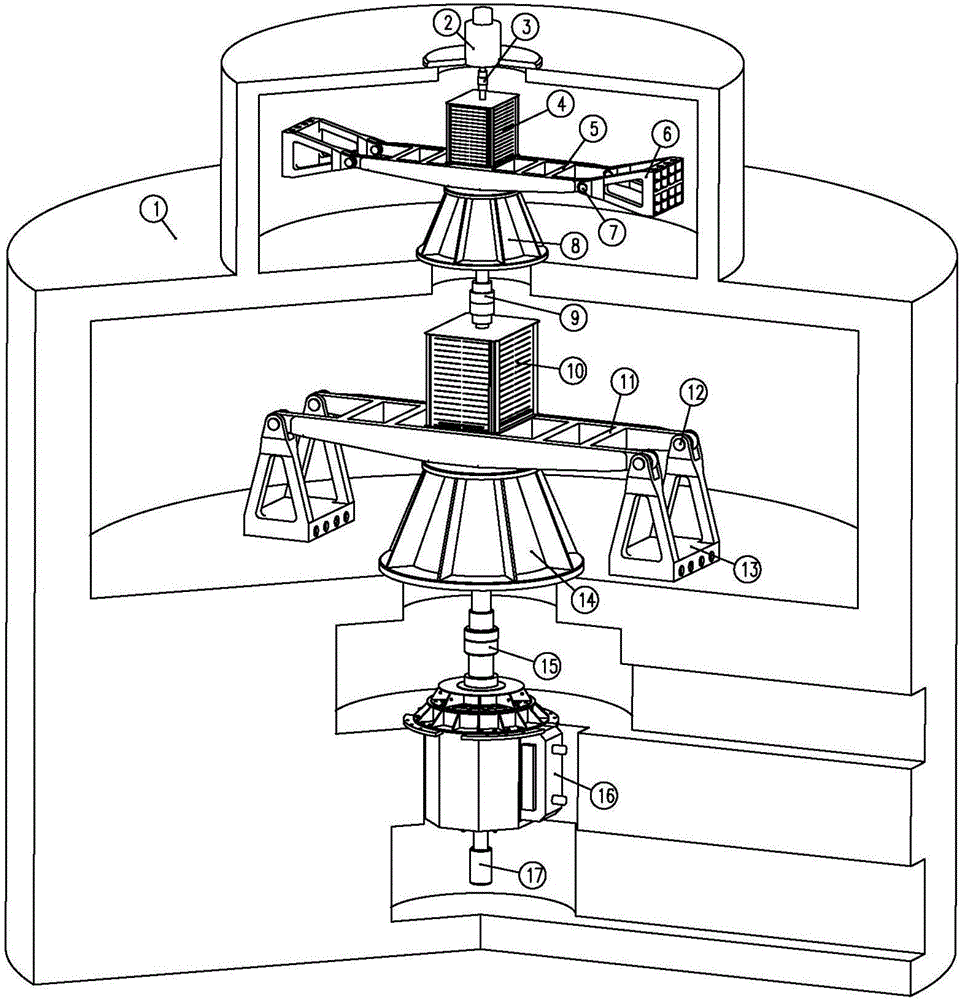

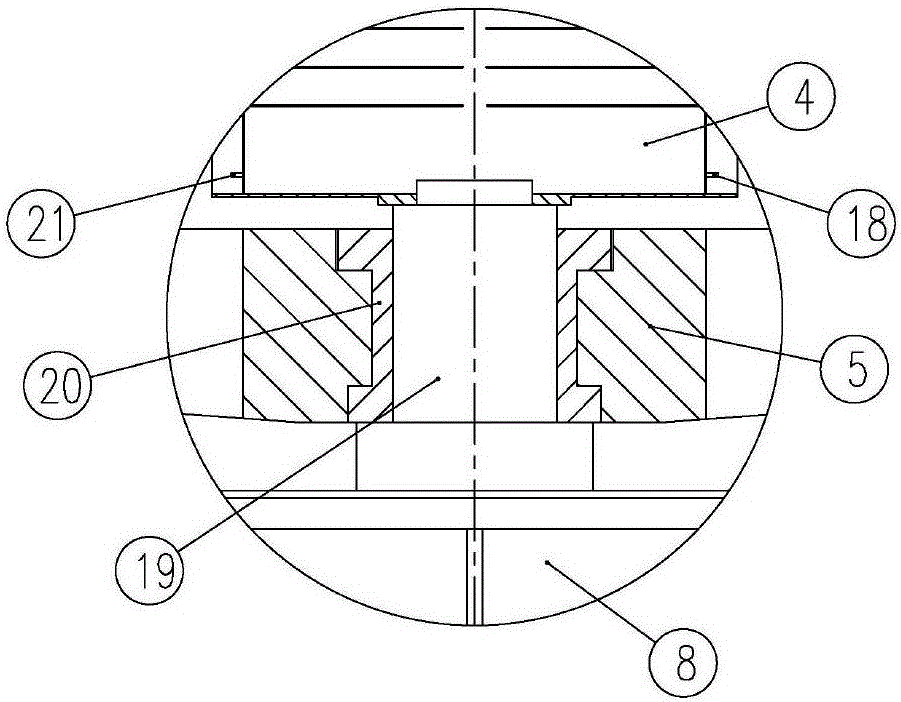

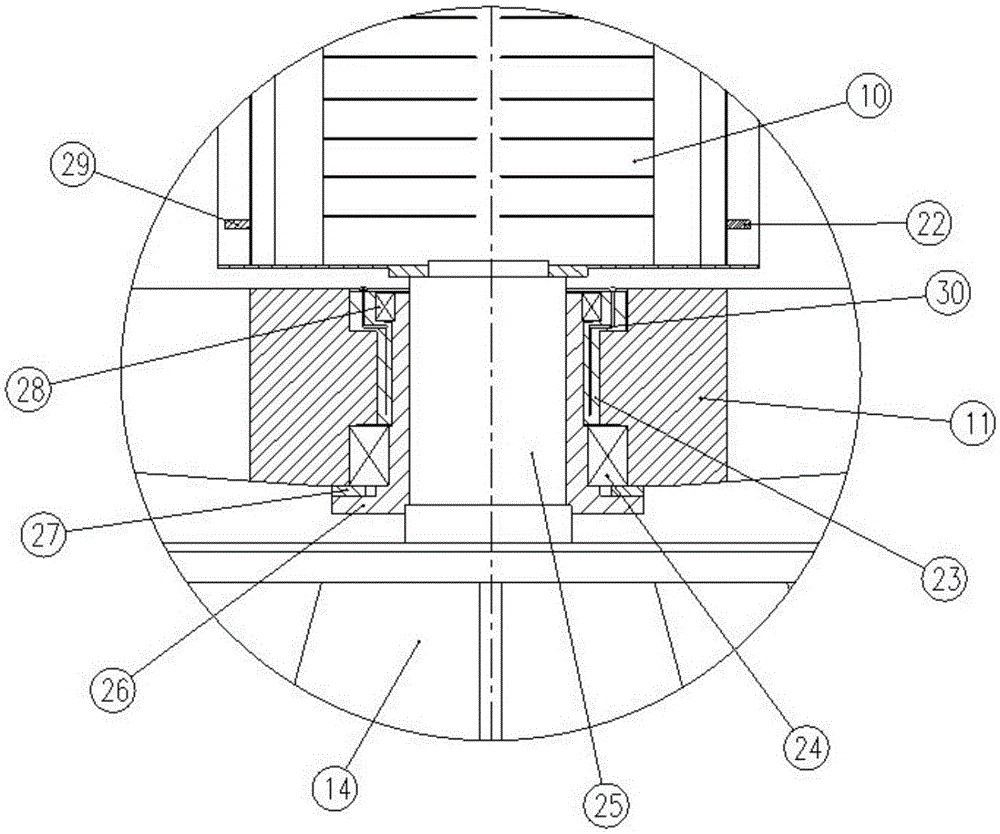

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as figure 1 , figure 2 with image 3 As shown, the present invention comprises civil construction main body 1, and civil construction main body 1 is provided with upper instrument cabin 2, vertically installed driving motor, slip ring assembly 17 connected on the driving motor, machine base, lower instrument cabin, horizontally installed rotary arm, pivoting arm pipeline joints and pivoting arm cable joints, the upper instrument cabin 2 is located at the top of the civil engineering main body 1, and the drive motor is located at the bottom of the civil engineering main body 1,

[0025] Wherein there are two machine bases, and they are respectively a large machine base 14 and a small machine base 8, and the small machine base 8 is located directly above the large machine base 14;

[0026] There are two lower instrument compartments, and they are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com