Piezo injector

A fuel injector, piezoelectric technology, used in fuel injection valves driven by fluid pressure, fuel injection devices, machines/engines, etc. Oiler degree of freedom, improvement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

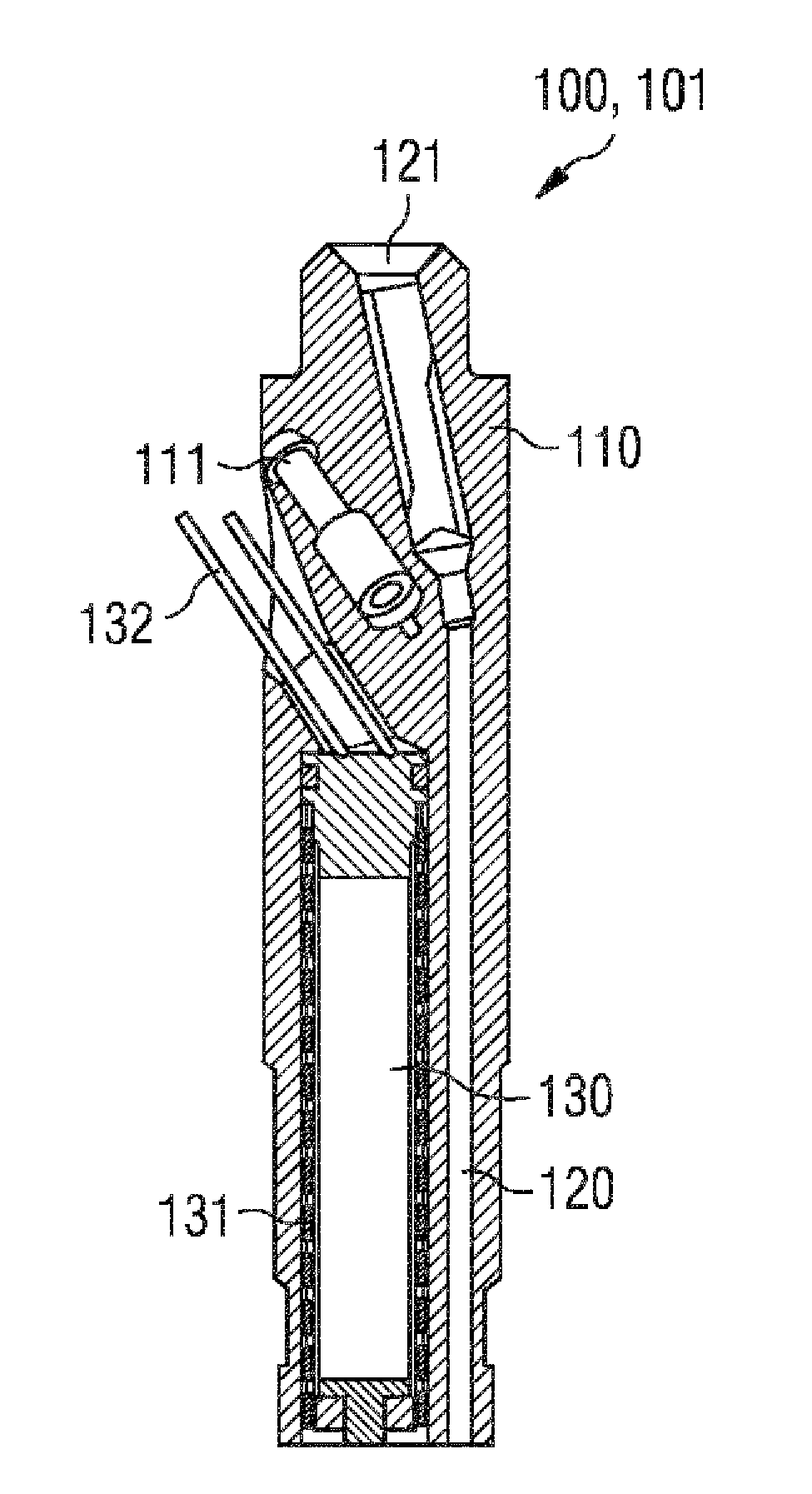

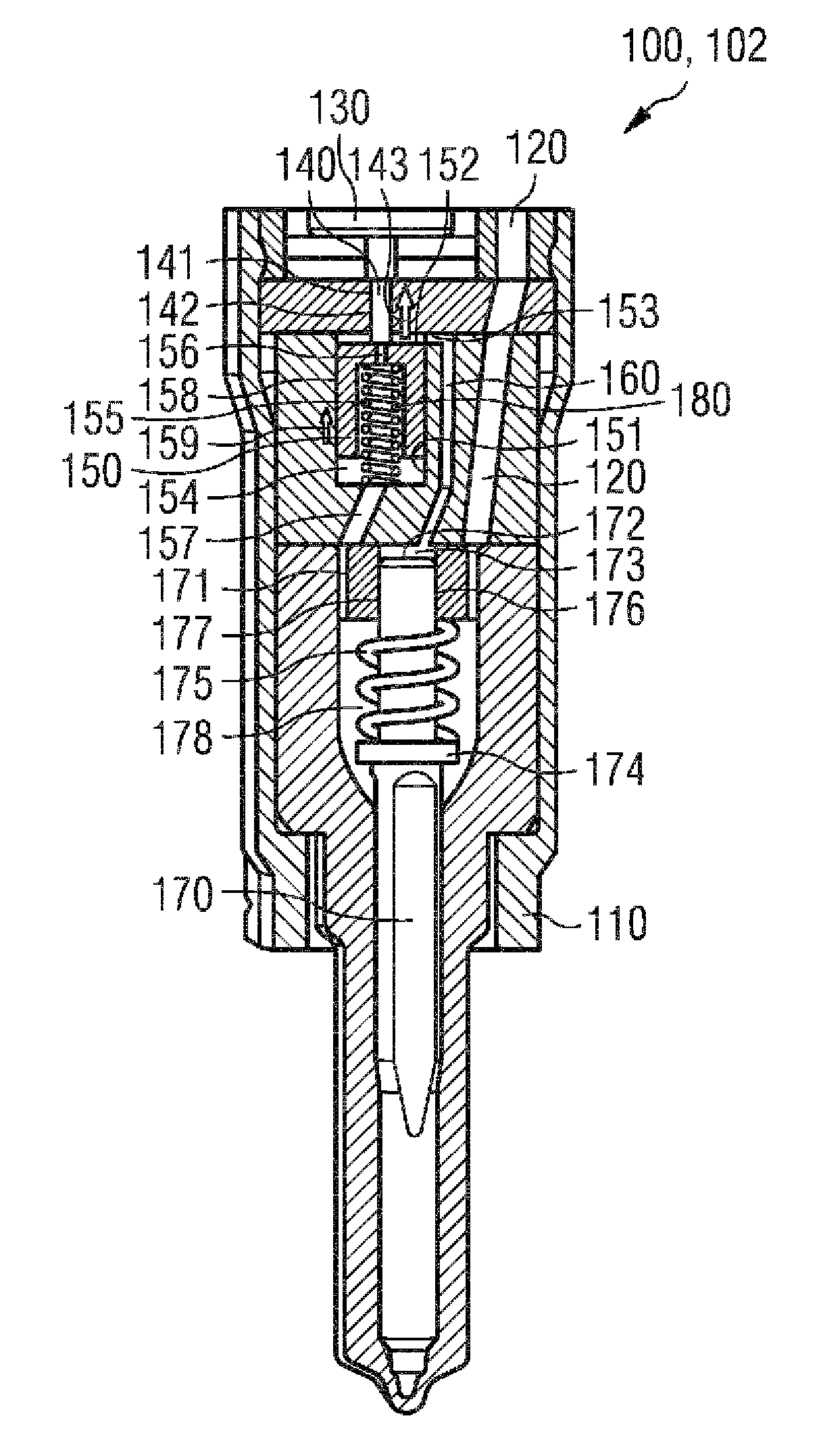

[0019] exist figure 1 with figure 2 A cross-sectional view of piezoelectric injector 100 is shown in . figure 1 The top half 101 of the piezo injector 100 is shown. figure 2 Bottom half 102 of piezo injector 100 is shown. The piezo injector 100 can be used to inject fuel in an internal combustion engine. For example, the piezo injector 100 can be used for injecting diesel in a common rail internal combustion engine.

[0020] The piezo injector 100 has an injector housing 110 . Injector housing 110 may consist of largely any material, since the thermal expansion properties of injector housing 110 are not significant. In particular, the injector housing 110 does not have to be made of low-expansion steel (Invar).

[0021] High-pressure bores 120 are arranged in injector housing 110 . Fuel under high pressure can be fed to the high-pressure opening via the high-pressure connection 121 . The high-pressure bore 120 extends in the longitudinal direction through the injecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com