Jacket with front piece and rear piece

A technology of upper and front pieces, applied in the field of clothing, can solve the problems of time-consuming and laborious, inconvenient rearranging actions on the spot, etc., and achieve the effect of easy wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

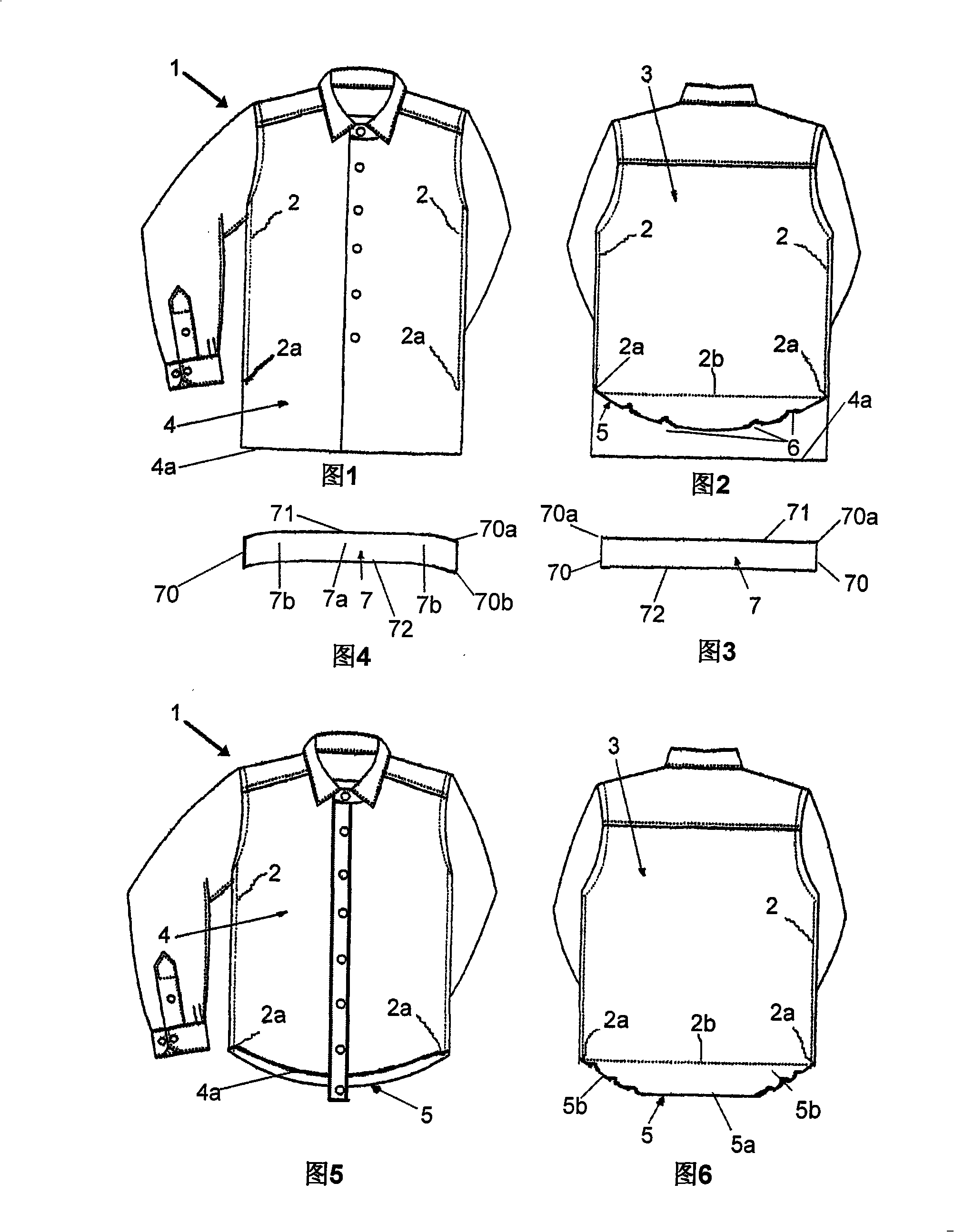

[0029] Take shirt size 175 / 96B as an example

[0030] The shirt 1 includes a front piece 4 and a back piece 3 connected to each other at the seams 2 on both sides. The back piece 3 has a back hem, which is generally arc-shaped with a lower arc, forming a lower edge 5. The length of the hem of the back piece is 58.4 cm, and the arc top of the arc-shaped lower edge 5 is perpendicular to a line 2b connecting the lower ends 2a of the seams 2 on both sides at a distance of 5 cm from the line. , Or the lower edge is 5 centimeters under the arc. Eight fold openings 6 are formed in the area of the lower edge 5, and these fold openings are symmetrically distributed with respect to the longitudinal centerline of the back sheet. The distance between the first fold opening and the side seam is 2 cm, and the distance between two adjacent folds remains the same, here it is 4 cm. After pleating, the horizontal waist 7 of the rectangle is sewn on the lower edge 5 in the upper edge area. The siz...

Embodiment 2

[0032] Take shirt size 175 / 96B as an example

[0033] The shirt 1 includes a front piece 4 and a back piece 3 connected to each other at the seams 2 on both sides. The back piece 3 has a back hem, which is generally arc-shaped with a lower arc, forming a lower edge 5. The length of the hem of the back piece is 60 cm, and the arc top of the arc-shaped lower edge 5 is at a distance of 3.3 cm from the line 2b in the direction perpendicular to the line 2b connecting the lower ends 2a of the seams 2 on both sides. , Or the lower edge 5 lower arc 3.3 cm. There are 8 fold openings 6 formed on the lower edge 5, and these fold openings are symmetrically distributed with respect to the longitudinal centerline of the back sheet. The distance between the first fold opening and the side seam is 2 cm, and the distance between two adjacent folds remains the same, here it is 4 cm. After pleating, the waist 7 is sewn on the lower edge 5. The size and shape of the horizontal waist 7 are as follows....

Embodiment 3

[0035] Take shirt size 175 / 96B as an example

[0036] The shape and size of the back sheet with the lower edge and the wrinkle opening basically corresponded to the first embodiment. Unlike Example 1, the front piece no longer has a traditional shape. Specifically, the front lower edge of the front piece 4 is in a downward arc shape extending between the lower end points of the seams on both sides, and the arc top of the front lower edge is located perpendicular to the line 2b. The distance of the connecting line is 1 cm. Here, the rectangular transverse waist 7 goes around the waist to the front panel 4, and is sewn on the lower edge 5 of the back panel 3 and the front lower edge 4a of the front panel 4 in the upper edge area. The size of the rectangle It is 96 cm long and 6.7 cm wide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com