Rotary column separator

A separator and rotary tower technology, applied in the field of sewage treatment devices, can solve the problems of short sewage flow path, complex structure and operation, low filtration efficiency, etc., and achieve the effect of improving filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

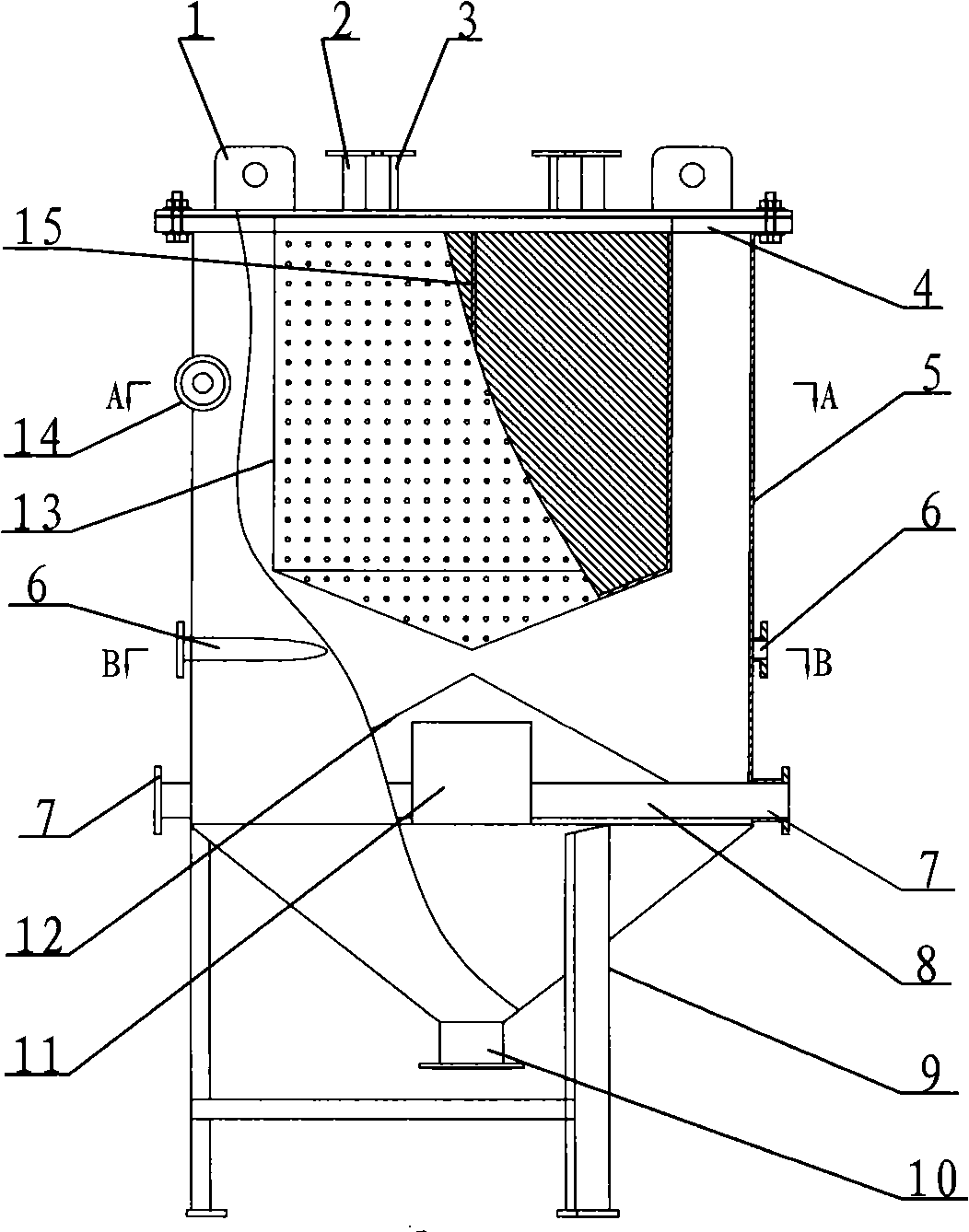

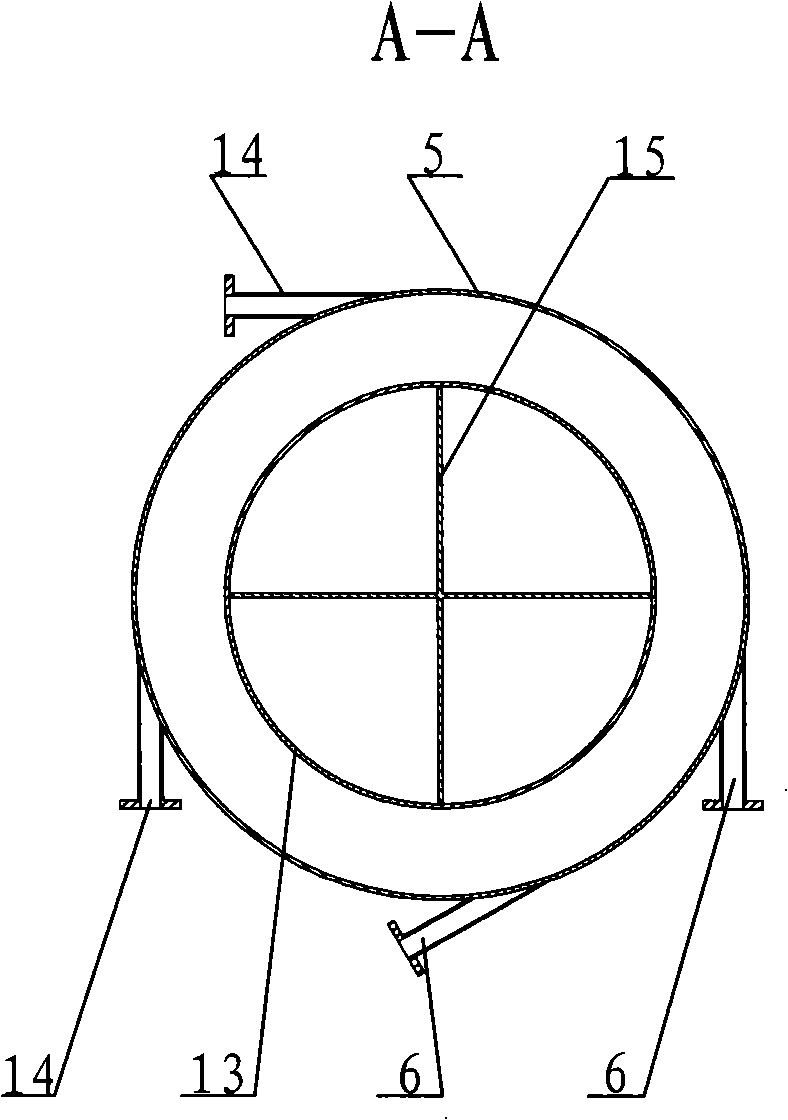

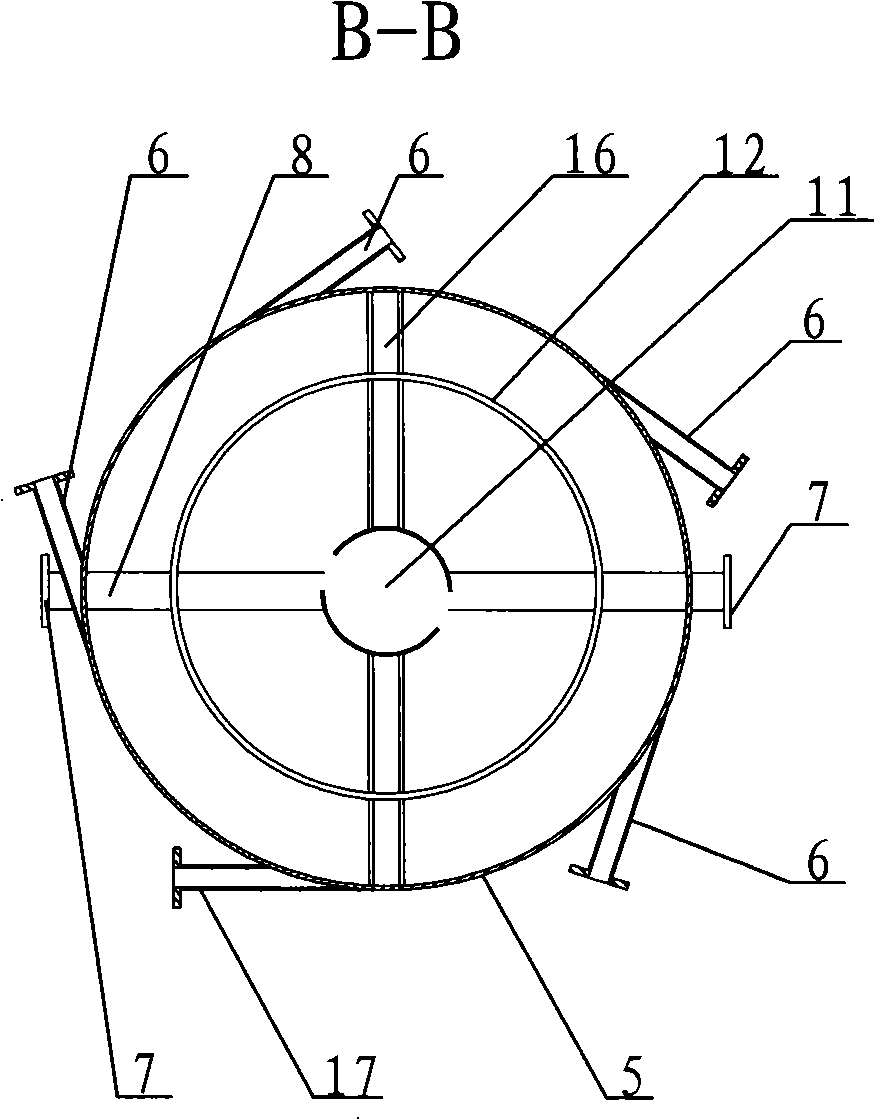

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0011] As can be seen from the accompanying drawings, the rotary column separator of this program includes a support 9 and a liquid storage cylinder 5 with a loam cake 4 on the support 9, and a feed port 17 is arranged on the side wall of the liquid storage cylinder 5. The bottom of the liquid cylinder 5 has a discharge port 10. The liquid storage cylinder 5 described in this program is a cylinder with a tapered bottom. The liquid storage cylinder 5 and the upper cover 4 form a closed pressure vessel. 17 is the feed port 17 that enters tangentially on the side wall of the liquid storage cylinder 5. On the side wall of the liquid storage cylinder 5, there are also the water inlet 6 that enters tangentially, the water outlet 14 that enters tangentially and the water outlet 14 that enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com