Independent MO source pipe line of semiconductor material growth apparatus and application thereof

A semiconductor and pipeline technology, applied in the field of metal organic chemical vapor phase epitaxy MOCVD growth equipment, can solve the problems of contamination, increasing the difficulty of AlGaN, and the difficulty of realizing AlGaN materials with high Al composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

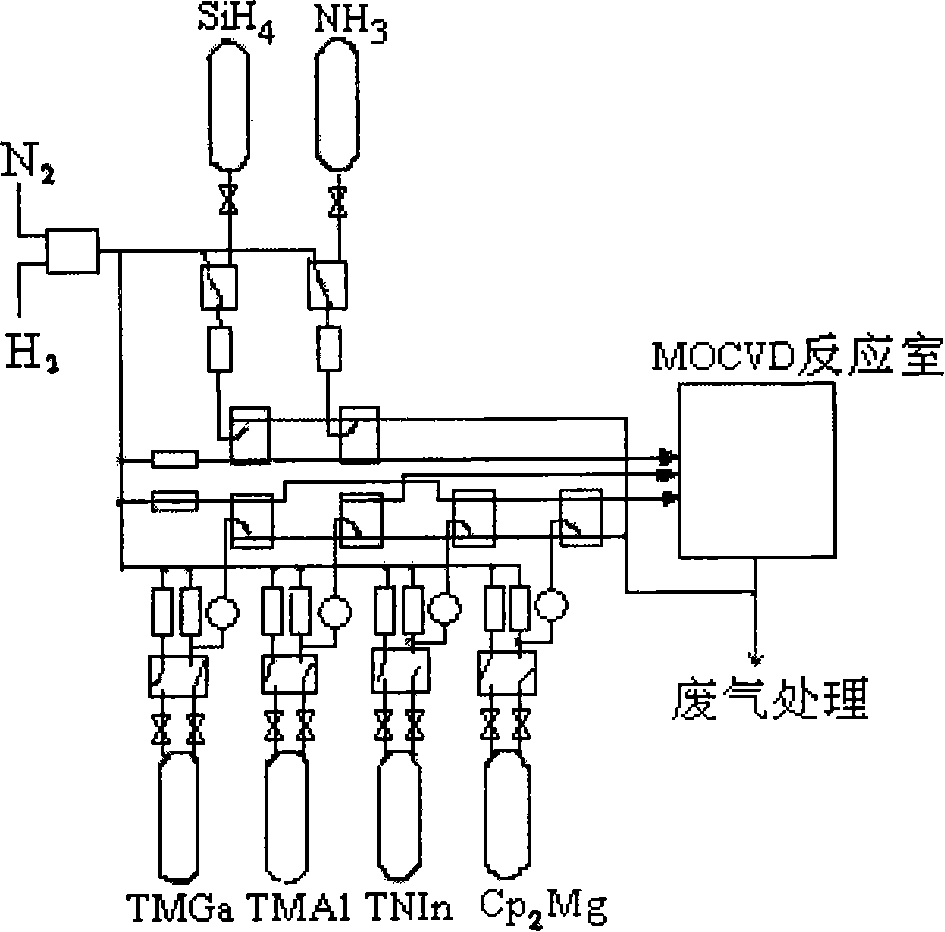

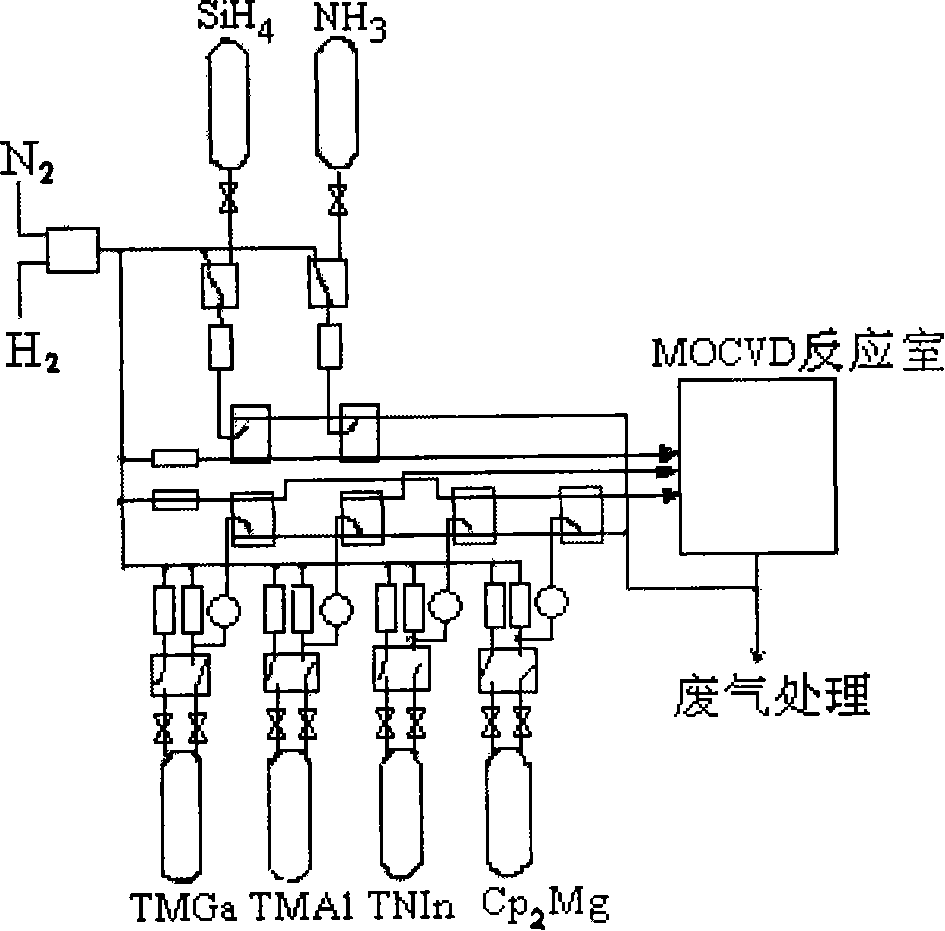

[0023] Chemical Vapor Deposition CVD technology is a method that utilizes gas-phase chemical reaction to form the required epitaxial film. It transports several gases containing the chemical composition of thin film elements to the surface of the substrate through an inner polished stainless steel tube, and uses different heating methods, such as resistance wire heating, radio frequency heating, light heating, etc., to promote gas phase reaction or surface phase reaction. reaction, the reaction product is deposited on the substrate surface to form an epitaxial film. Metal-organic chemical vapor deposition (MOCVD) technology is a CVD technology that transports metal elements in compound semiconductors to the surface in the form of metal-organic MO sources. The MO source usually uses trimethylgallium TMGa, trimethylaluminum TMAl, trimethylindium TMIn as the Group III metal source, NH 3 As a source of group V nitrogen. For the growth of III-nitride binary alloys, the chemical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com