Production technology for combining air conduit by using shape hoop

A ventilation duct and production process technology, applied in the field of ventilation duct production process, can solve the problems of poor bonding firmness of ventilation ducts, affecting the use effect of ventilation ducts, poor reliability, etc., so as to ensure the cooling and heating effect, low noise, The effect of a large connection surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

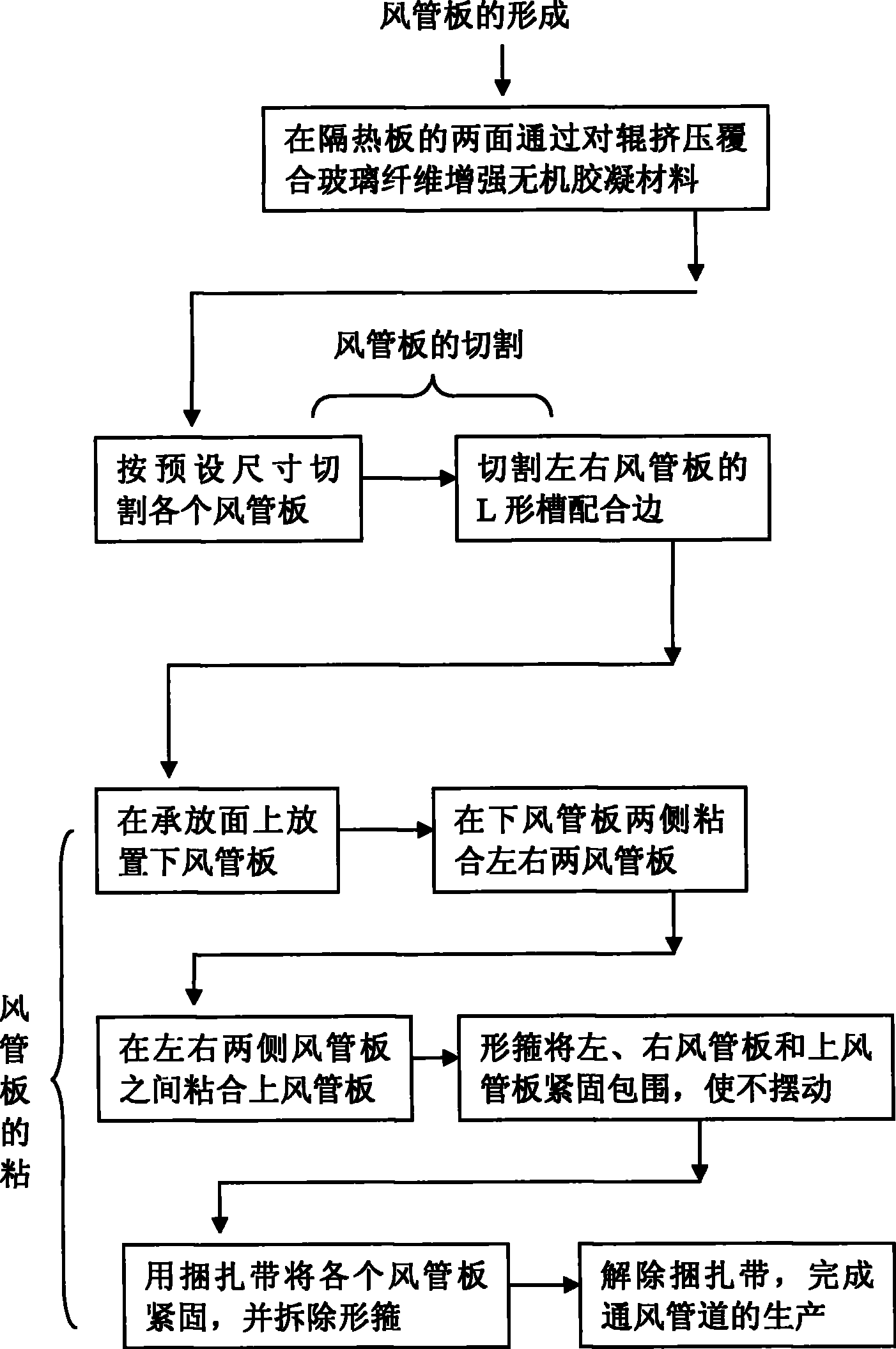

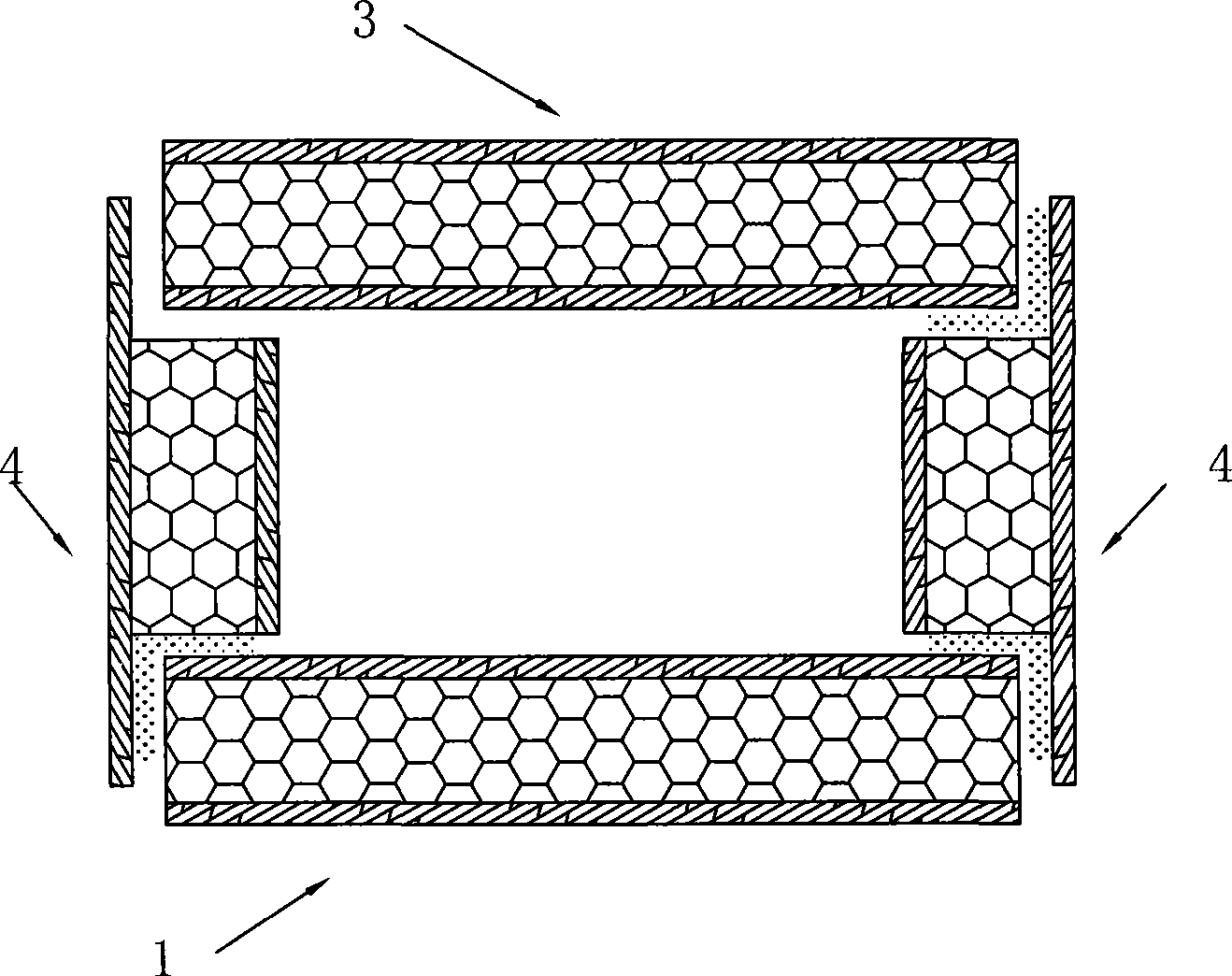

[0019] Embodiment 1: the production technology of application shape hoop combined ventilation duct, as figure 1 and Figure 4 As shown, the steps of the process are: step 1, making the air duct plate, step 2, cutting the air duct plate, step 3, bonding the air duct plate to form an air duct; the bonding process of the air duct plate is: a. Place the lower air duct plate 1 horizontally, glue the left and right air duct plates 4 on both sides of the lower air duct plate, then glue the upper air duct plate 3 between the left and right air duct plates 4, and place the several The shape hoop 8 is inserted from the lateral sides of the upper air duct plate 3 to fasten and surround the left and right air duct plate 4 and the upper air duct plate 3. After the binding is completed and the positioning is correct, remove the shape hoop, and finally the adhesive After curing, remove the strapping 5 . The ends of the lower air duct plate 1 and the upper air duct plate 3 are misaligned ...

Embodiment 2

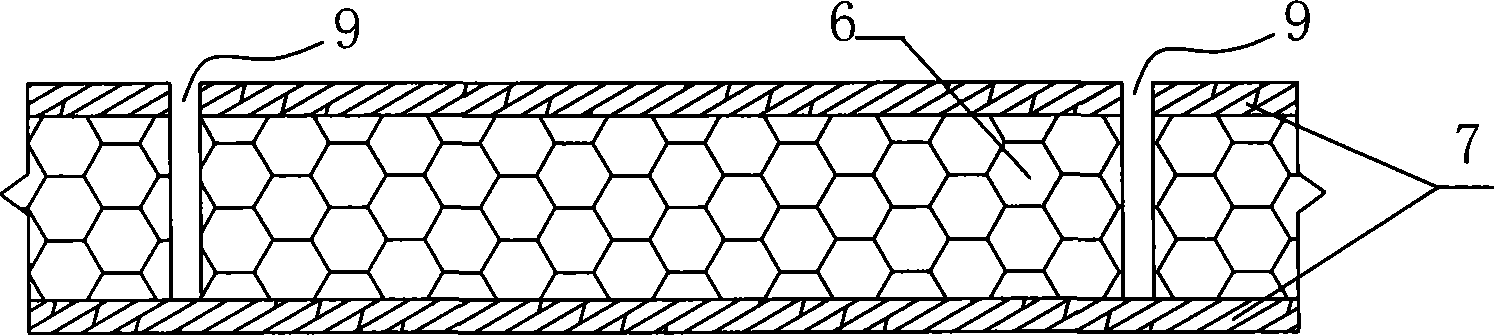

[0022] Embodiment 2: The process of cutting the air duct plate is: I, cutting each air duct plate according to the preset size; II, cutting the left and right air duct plates 4 and the upper and lower air duct plates to form a cutting seam 9 respectively. The distance from the cutting seam 9 to the mating edge is the thickness of the air duct plate, and the depth of the cutting seam 9 is three quarters of the thickness of the air duct plate. After transporting each air duct plate to the place where the combined air duct is pre-installed, cut two L-shaped grooves on both sides where the left and right air duct plates 4 cooperate with the upper and lower air duct plates. The inner fiber-reinforced inorganic viscose layer 7 and the heat insulation board 6 are removed at the mating edge, and the outer fiber-reinforced inorganic viscose layer 7 is retained, and two L-shaped groove mating edges are formed on the left and right air duct plates 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com