Drop panel jack-in wrought steel hook tail frame

A plug-in, hook tail frame technology, applied in railway couplings, railway car body parts, transportation and packaging, etc., can solve the problems of the hook tail pin 5 falling off, the connection device being separated, the bolt 3 breaking and other problems, so as to prolong the service life. , the effect of increasing the effective thickness, density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

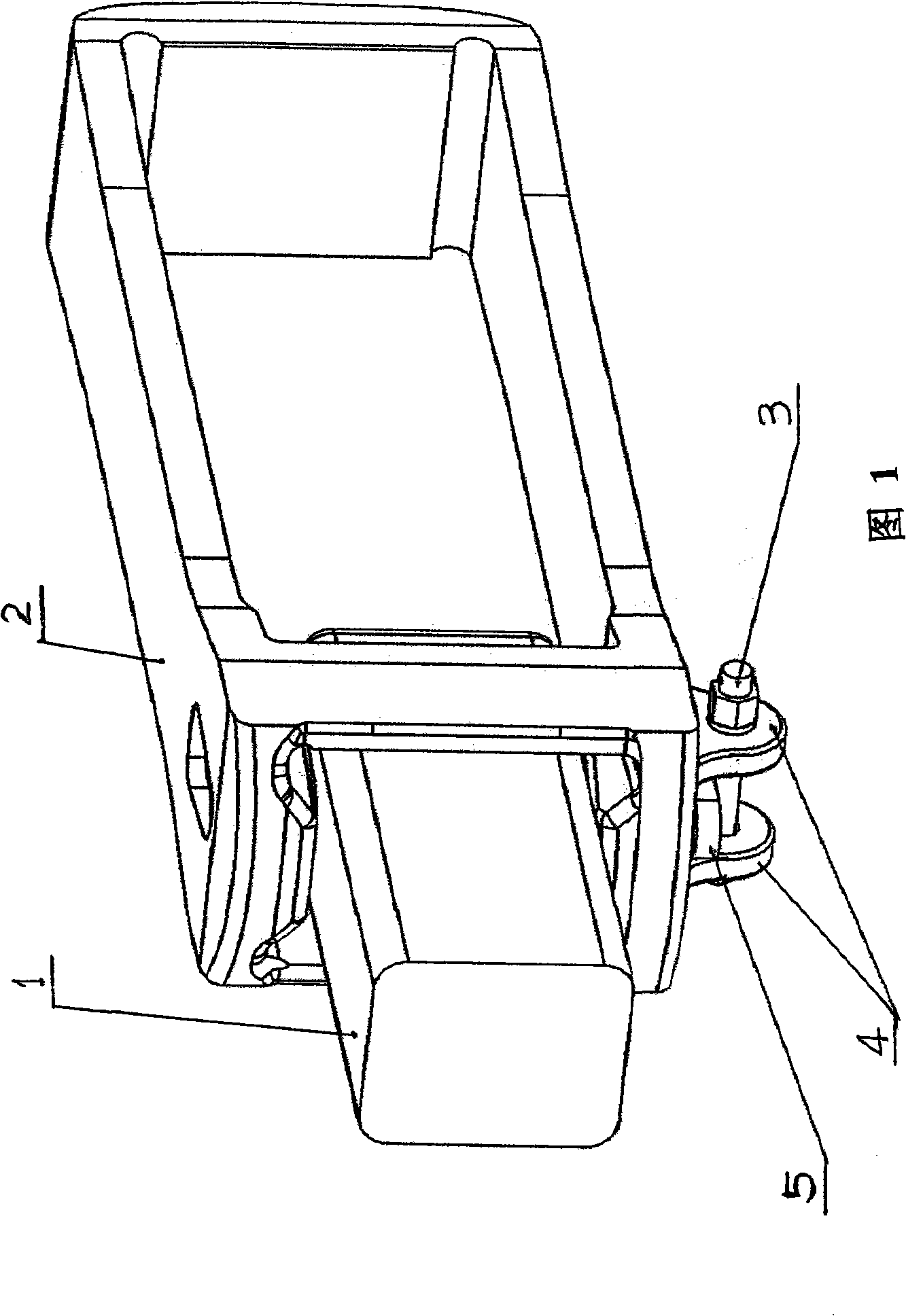

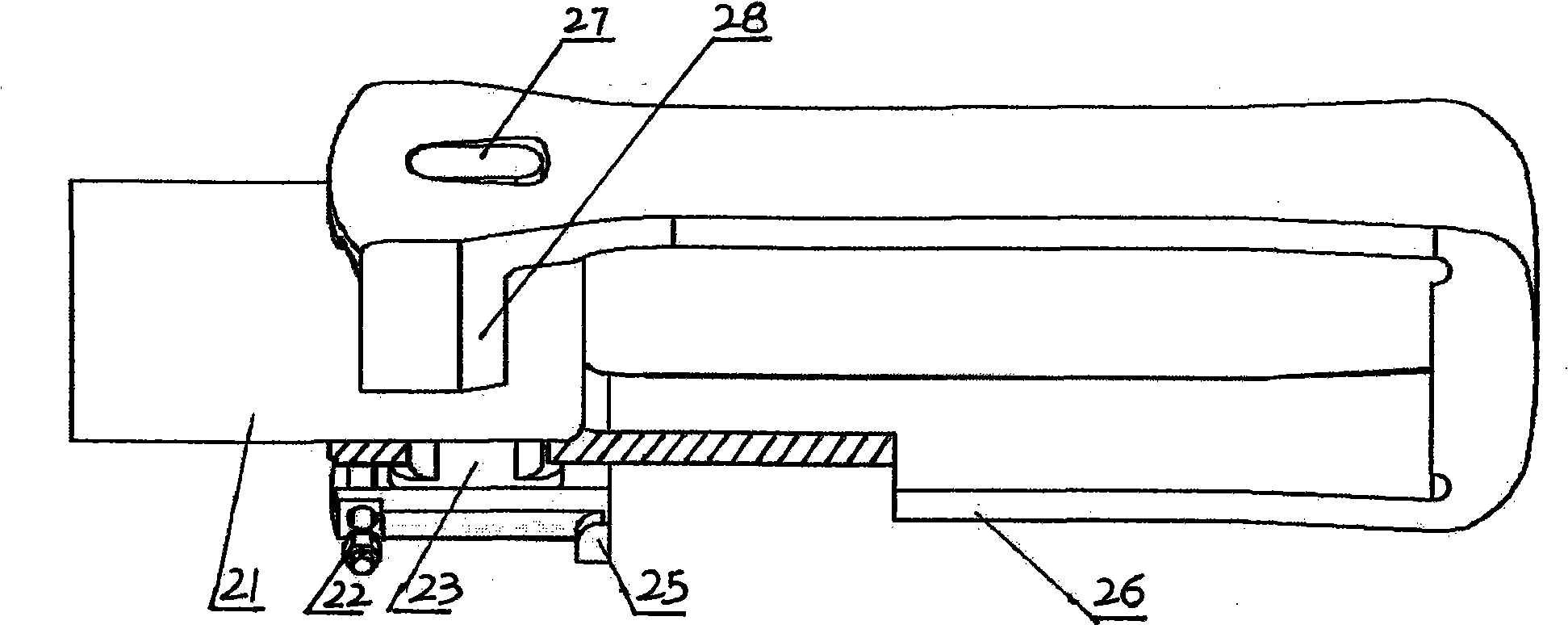

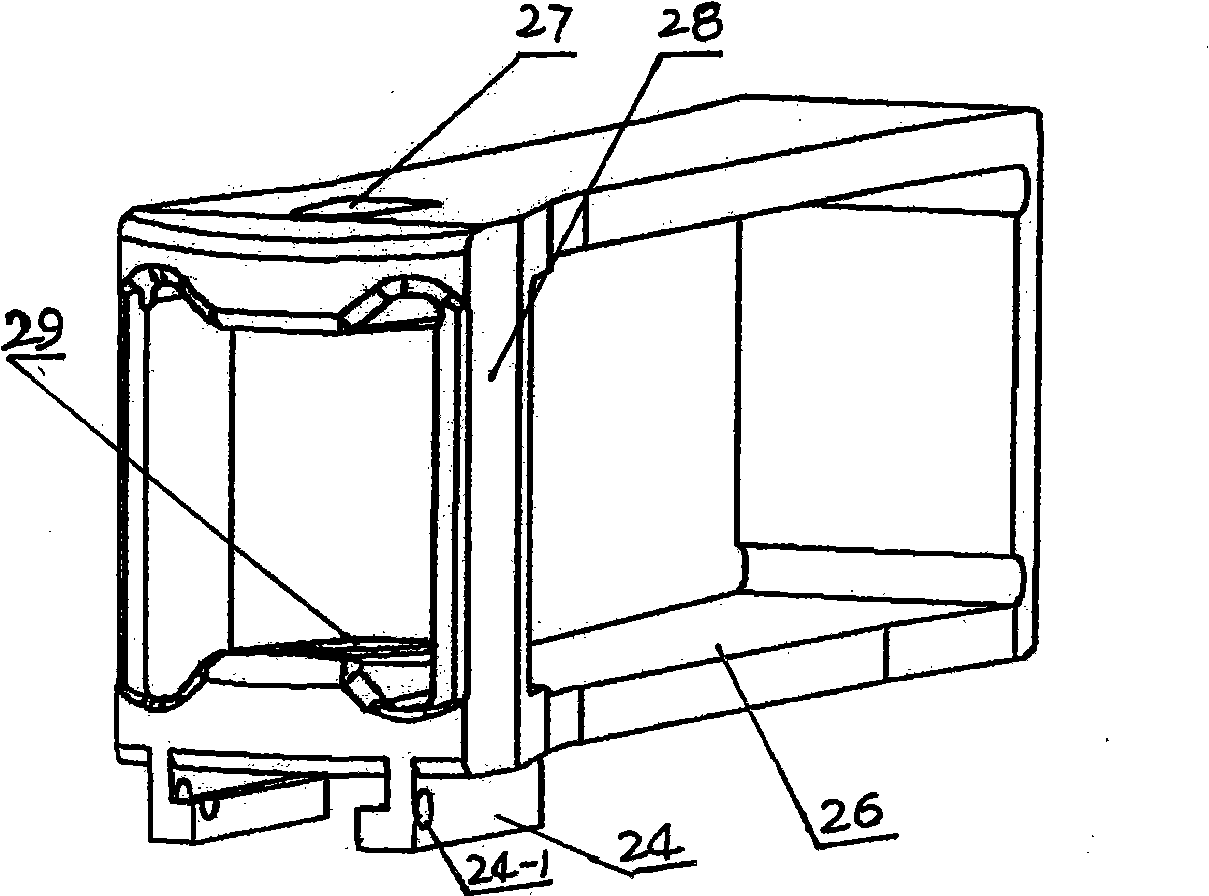

[0017] The accompanying drawings disclose two specific embodiments of the present invention without limitation, and the present invention will be further described as follows in conjunction with the accompanying drawings.

[0018] see figure 2 with image 3 , 21 in the figure is the coupler tail, 22 is the positioning bolt, 23 is the coupler pin, 24 is two L-shaped slideways, 24-1 is the slideway hole, 25 is the forged steel plate, 26 is a U-shaped forged Steel frame, 27 is upper pin hole, and 28 is forged steel side plate, and 29 is lower pin hole. Figure 4 Middle 25-1 is supporting plate positioning hole, 25-2 is inverted L-shaped slide bar, and 25-3 is the boss with inclined-plane. The two sides of the lower pin hole 29 of the forged steel frame are respectively provided with L-shaped slideways 24, and the two sides of the forged steel supporting plate 25 are respectively provided with inverted L-shaped slide bars 25- 2. The forged steel supporting plate 25 is plugged a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap