Anticorrosive oil automatic painting apparatus for adjustable rails

A technology of anti-rust oil and guide rails, which is applied in transportation, packaging, elevators, etc., can solve the problems of workers' health damage, shorten the life of T-shaped guide rails, and affect the smoothness of the working surface, so as to achieve a high level of production automation and reduce labor intensity , the effect of expanding the scale of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

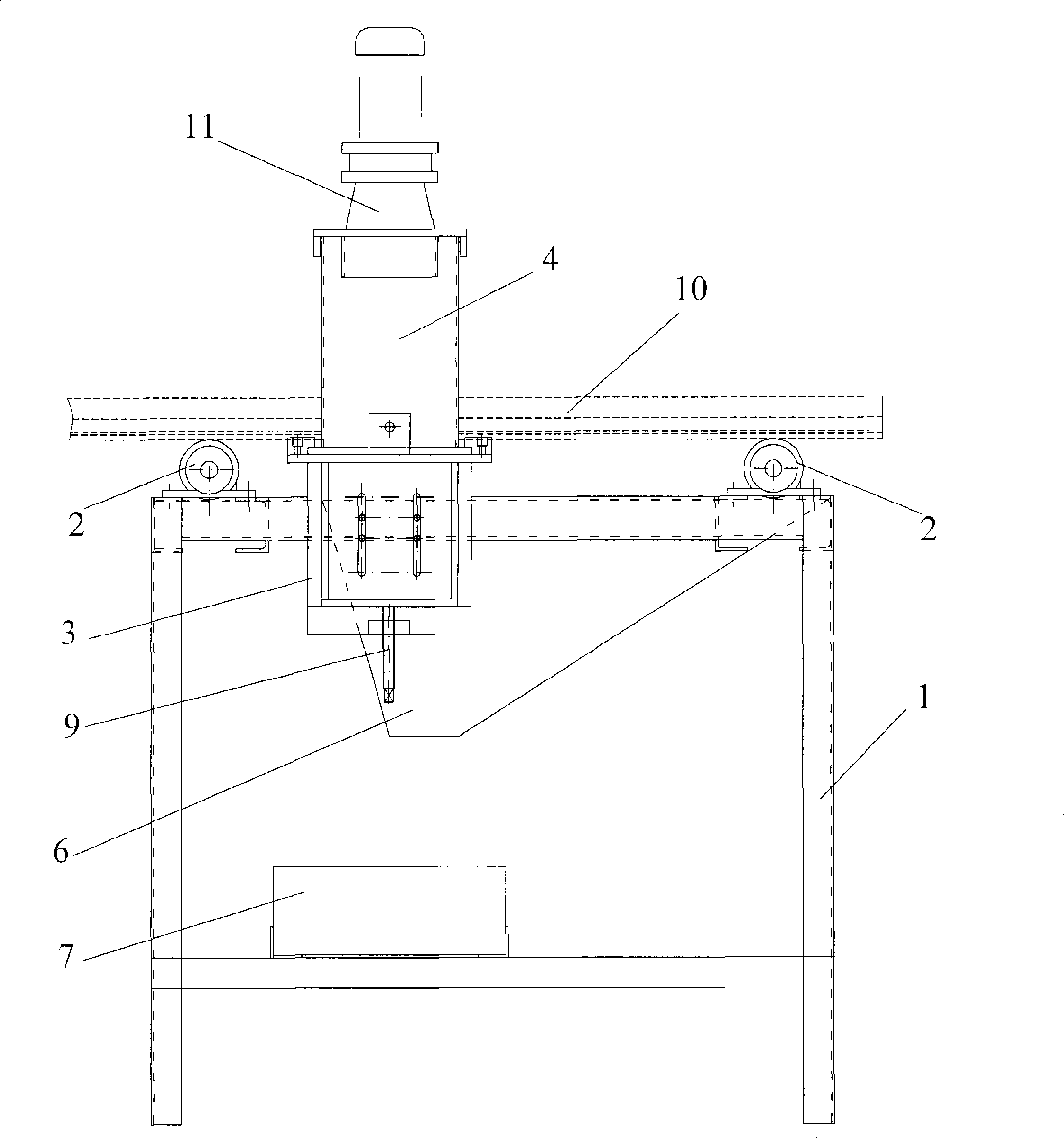

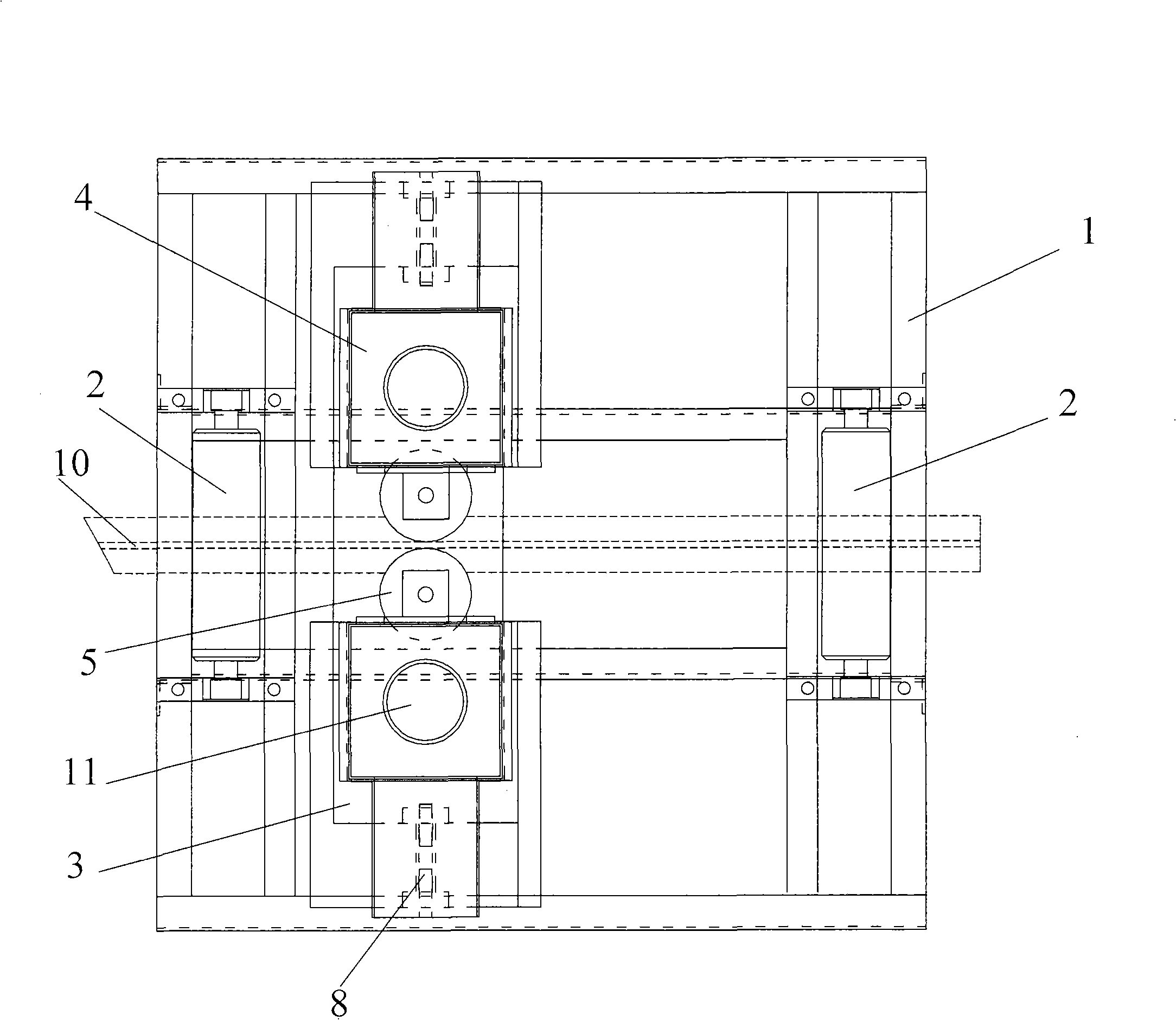

[0013] Example: such as figure 1 and figure 2 As shown, an adjustable guide rail anti-rust oil automatic application device includes a base 1, an oiling unit fixed above the base 1 and an adjustable roller 2, and the oiling unit includes symmetrically arranged on both sides of the guide rail 10 Two sets, the oiling unit includes an oiling frame 3 fixed to the base 1, an oiling tank 4 is fixed on the oiling frame 3, and the inner side of the oiling tank 4 is installed to roll with the working surface on the side of the guide rail 10. The oiling roller 5 that contacts, the described oiling roller 5 part is located in the oil filling tank 4, and the height of the bottom surface of the oil filling tank 4 is equivalent to the bottom of the side working surface of the guide rail 10. The 10T-shaped horizontal part of the guide rail lies outside on the adjustable roller 2, and is driven by an external motor to make a one-way linear motion on the automatic smearing device, and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com