Electroconductive thermoplastic elastomer composition, its manufacturing method and molded product

A thermoplastic elastomer and composition technology, applied in the field of conductive thermoplastic elastomer composition, can solve problems such as no description or hint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

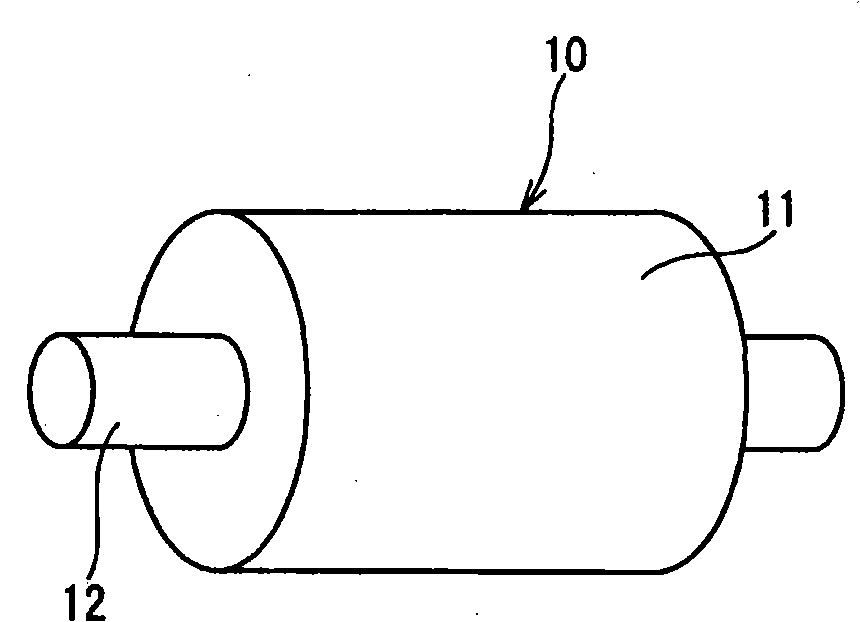

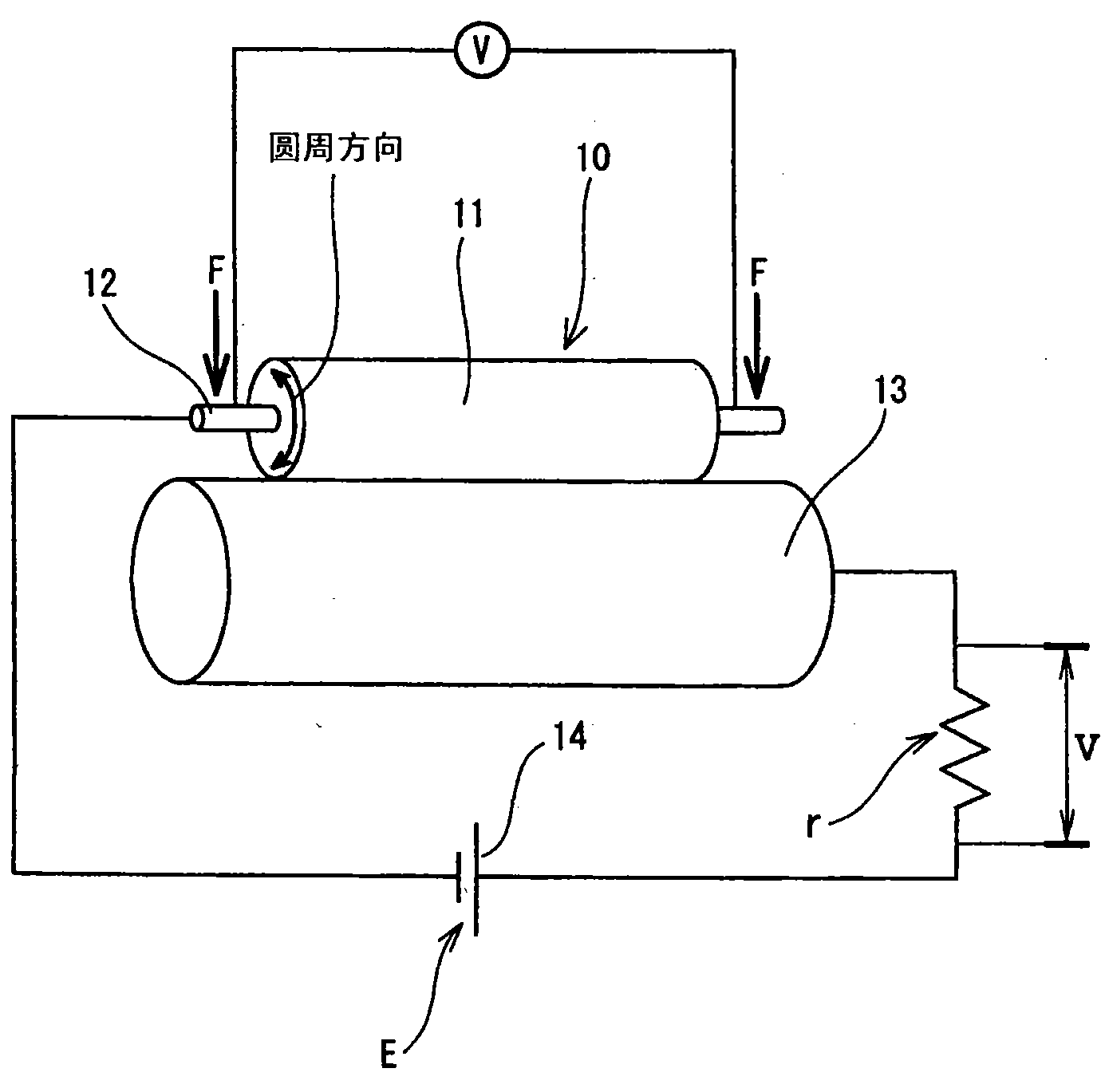

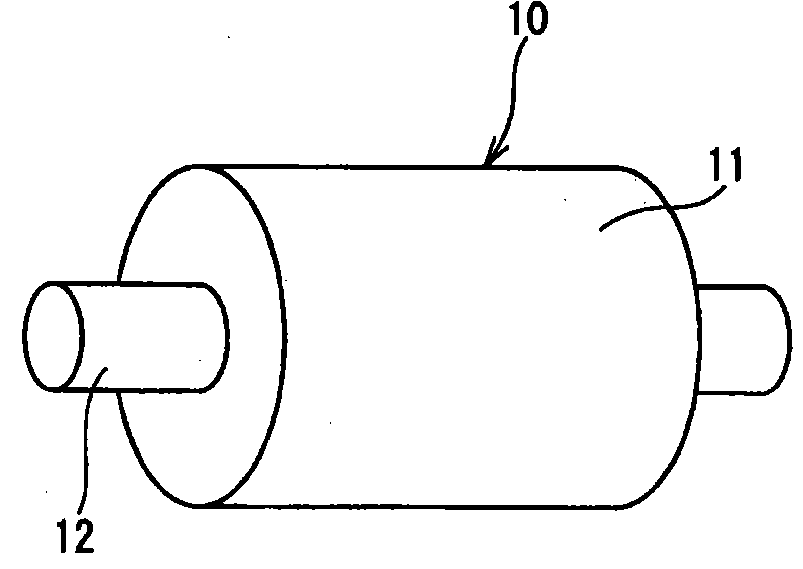

[0150] The first embodiment of the present invention will be described below with reference to the accompanying drawings.

[0151] The conductive thermoplastic elastomer composition in the first embodiment includes component (A) composed of a base polymer comprising a mixture of an olefin resin and a styrene thermoplastic elastomer, dynamically cross-linked and dispersed in the olefin resin Thermoplastic elastomer composition of ethylene-propylene-diene rubber (EPDM) or / and acrylonitrile-butadiene rubber (hereinafter referred to as NBR) in a mixture with styrene thermoplastic elastomer; consisting of EO-PO-AGE copolymer and a component (B) consisting of an ion-conducting agent of a metal salt contained in an EO-PO-AGE copolymer, the metal salt being composed of a metal cation and an anion having a fluorine group and a sulfonyl group; and consisting of ethylene-acrylate- Component (C) composed of a maleic anhydride copolymer. Component (B) consisting of an ion-conducting agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com