Aluminum alloy rolled plate and producing method thereof

A production method and technology of aluminum alloy, which are applied in metal rolling, metal rolling, rolling mill control device and other directions, can solve the problems of short service time, unstable performance, easy environmental pollution and other problems of mirror panels, and achieve the advantages of popularization and application, The effect of light weight and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

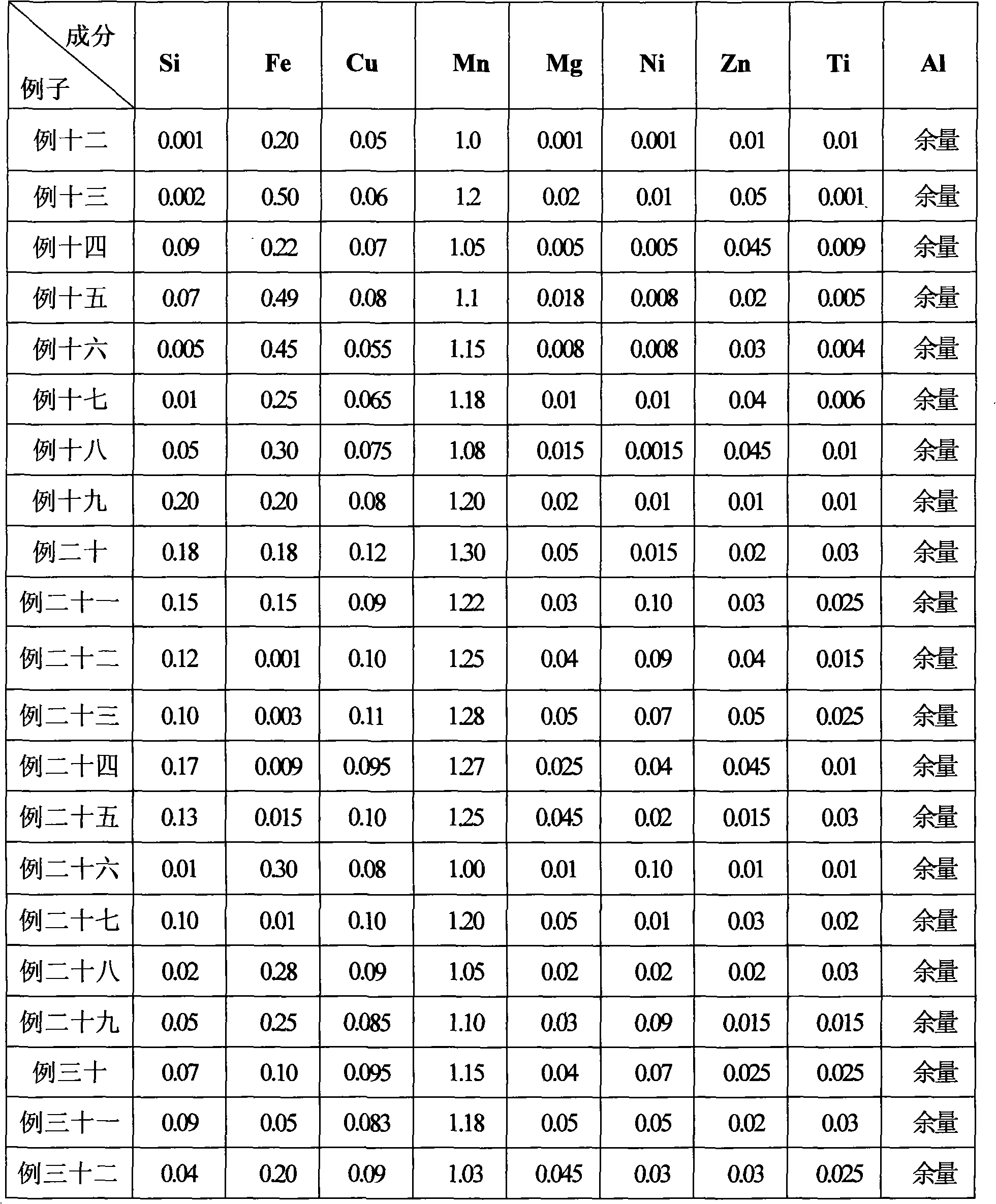

Examples

Embodiment 1

[0024] Embodiment 1, aluminum alloy rolled pattern plate and production method thereof,

[0025] (1) The composition of the aluminum alloy rolled checkered plate, expressed in parts by weight, is 0.001 part of Si, 0.50 part of Fe, 0.05 part of Cu, 1.0 part of Mn, 0.001 part of Mg, 0.1 part of Ni, 0.05 part of Zn, 0.001 part of Ti and the rest Amount of Al, a total of 100 parts;

[0026] During production, the mixed metal is smelted at 770°C for 5 minutes. When the charge is completely melted and reaches the melting temperature range, the slag is removed, and then thoroughly stirred. After the thorough stirring is ensured, when the melt temperature reaches 730°C, samples are taken and tested. Whether the ingredients are qualified; and carry out the first stirring at a speed of 50 rpm, stirring for 5 minutes; after the first stirring, stay for 10-15 minutes, wait for the charge to be fully dissolved, adjust the temperature to 740-760°C, and then stir for 5-10 minutes , to obtai...

Embodiment 2

[0031] Embodiment 2, aluminum alloy rolled checkered plate and production method thereof, the same as embodiment 1 will not be repeated, the difference is:

[0032] (1) Composition: 0.20 parts of Si, 0.001 parts of Fe, 0.12 parts of Cu, 1.3 parts of Mn, 0.05 parts of Mg, 0.001 parts of Ni, 0.001 parts of Zn, 0.03 parts of Ti and the balance Al, totaling 100 parts; Melting at ℃ for 5 minutes;

[0033] (2) Refining with nitrogen and chlorine mixed gas for 20 minutes under the condition of 740 ° C, and standing for 9 hours, the standing temperature is 750 ° C; the thickness of the product is 7.0 ~ 7.8 mm under the condition of the front box temperature of 715 ° C and the speed of 1000 mm / min. rough material;

[0034] (3) The rough material is rolled to a thickness of 2.50mm through 2 to 4 passes of a four-fold cold rolling mill at a medium temperature of 60°C; the rolling speed is 100m / min;

[0035] (4> After bending and straightening, quench at 410°C for 10h.

Embodiment 3

[0036] Embodiment three, aluminum alloy rolled checkered plate and its production method, the same as embodiment one will not be repeated, the difference is:

[0037] (1) Composition: 0.005 parts of Si, 0.45 parts of Fe, 0.10 parts of Cu, 1.2 parts of Mn, 0.005 parts of Mg, 0.005 parts of Ni, 0.04 parts of Zn, 0.003 parts of Ti and the balance of Al and unavoidable impurities, totaling 100 parts; Melt the mixture at 760°C for 18 minutes;

[0038] (2) Refining at 750°C for 18 minutes, standing still for 11 hours, the standing temperature is 740°C. Under the condition of head box temperature of 700℃ and speed of 150mm / min, blanks of 7.0-7.8mm are produced;

[0039] (3) Rolled to 2.0-3.0mm by four-fold cold rolling mill; rolling speed is 10m / min;

[0040] (4>Quenching at 450°C for 10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com