A kind of radiation cross-linking low-smoke and halogen-free flame retardant fuel for automobile wire and its preparation method

A technology for automobile wires and fuel resistance, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc. It can solve the problems of low decomposition temperature of polyvinyl chloride, high material density, energy-saving requirements, and poor high temperature resistance. Achieve the best production extrusion processing performance, meet the high-speed production needs, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

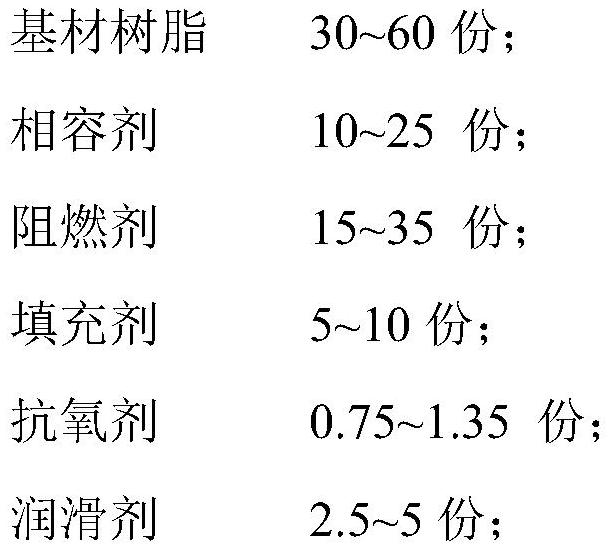

[0040] An irradiation cross-linked low-smoke halogen-free flame-retardant material for automobile wires. The raw material components and proportions are as follows: 30 parts of base resin; 10 parts of compatibilizer; 15 parts of flame retardant; 5 parts of filler; 0.75 parts of oxygen agent; 2.5 parts of lubricant; 1.5 parts of sensitizer.

[0041] Among them, based on the total weight of the substrate resin, linear low-density polyethylene accounts for 66 percent; ethylene-butyl acrylate copolymer accounts for 17 percent; and ethylene-propylene copolymer resin accounts for 17 percent.

[0042] The compatibilizer is polyethylene grafted maleic anhydride copolymer.

[0043] The flame retardant is a combination of melamine polyphosphate and high molecular weight ammonium polyphosphate, and the mass ratio of melamine polyphosphate and high molecular weight ammonium polyphosphate is 3:1.

[0044] The filler is a combination of ultrafine silica powder and calcium carbonate silica ...

Embodiment 2

[0049] An irradiation cross-linked low-smoke halogen-free flame-retardant material for automobile wires. The raw material components and proportions are as follows: 40 parts of base resin; 15 parts of compatibilizer; 25 parts of flame retardant; 5 parts of filler; 0.9 parts of oxygen agent; 3 parts of lubricant; 2 parts of sensitizer.

[0050] Wherein, based on the total weight of the substrate resin, linear low-density polyethylene accounts for 50 percent; ethylene-butyl acrylate copolymer accounts for 25 percent; and ethylene-propylene copolymer resin accounts for 25 percent.

[0051] The compatibilizer is ethylene-octene copolymer grafted with maleic anhydride copolymer.

[0052] The flame retardant is a combination of melamine polyphosphate and high molecular weight ammonium polyphosphate, and the mass ratio of melamine polyphosphate and high molecular weight ammonium polyphosphate is 3:1.

[0053] The filler is a combination of ultrafine silica powder and calcium carbona...

Embodiment 3

[0058] An irradiation cross-linked low-smoke halogen-free flame-retardant material for automobile wires. The raw material components and proportions are as follows: 50 parts of base resin; 15 parts of compatibilizer; 30 parts of flame retardant; 8 parts of filler; 1.1 parts of oxygen agent; 3.5 parts of lubricant; 2 parts of sensitizer.

[0059] Wherein, based on the total weight of the substrate resin, linear low-density polyethylene accounts for 50 percent; ethylene-butyl acrylate copolymer accounts for 30 percent; and ethylene-propylene copolymer resin accounts for 20 percent.

[0060] The compatibilizer is ethylene-octene copolymer grafted with maleic anhydride copolymer.

[0061] The flame retardant is a combination of melamine polyphosphate and high molecular weight ammonium polyphosphate, and the mass ratio of melamine polyphosphate and high molecular weight ammonium polyphosphate is 3:1.

[0062] The filler is a combination of superfine silica powder and calcium carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com