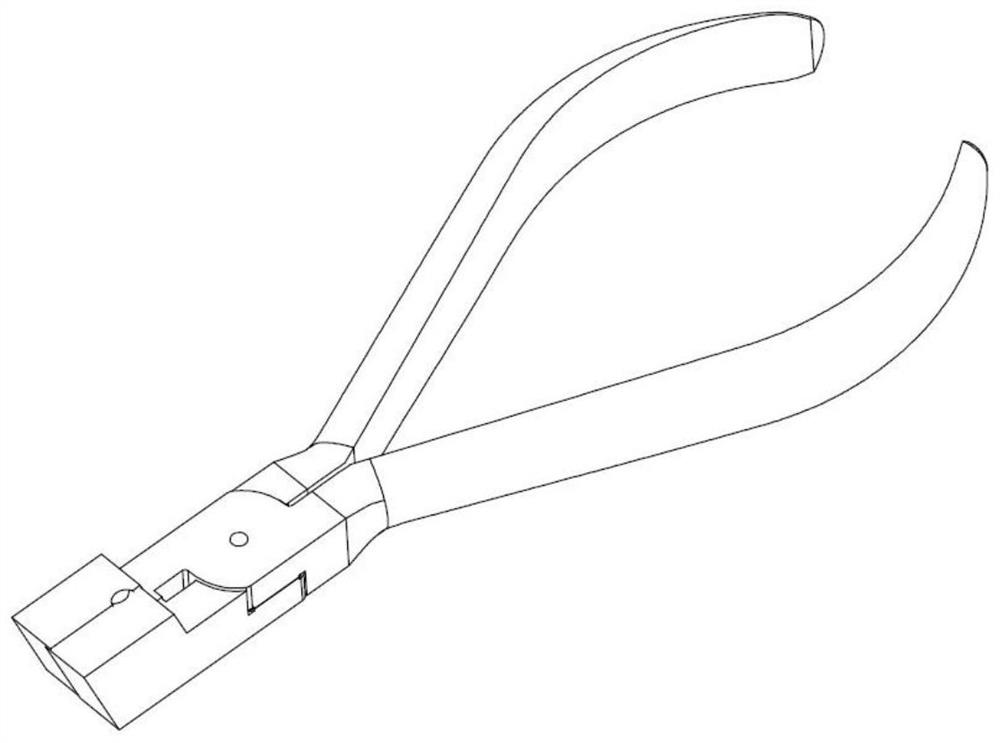

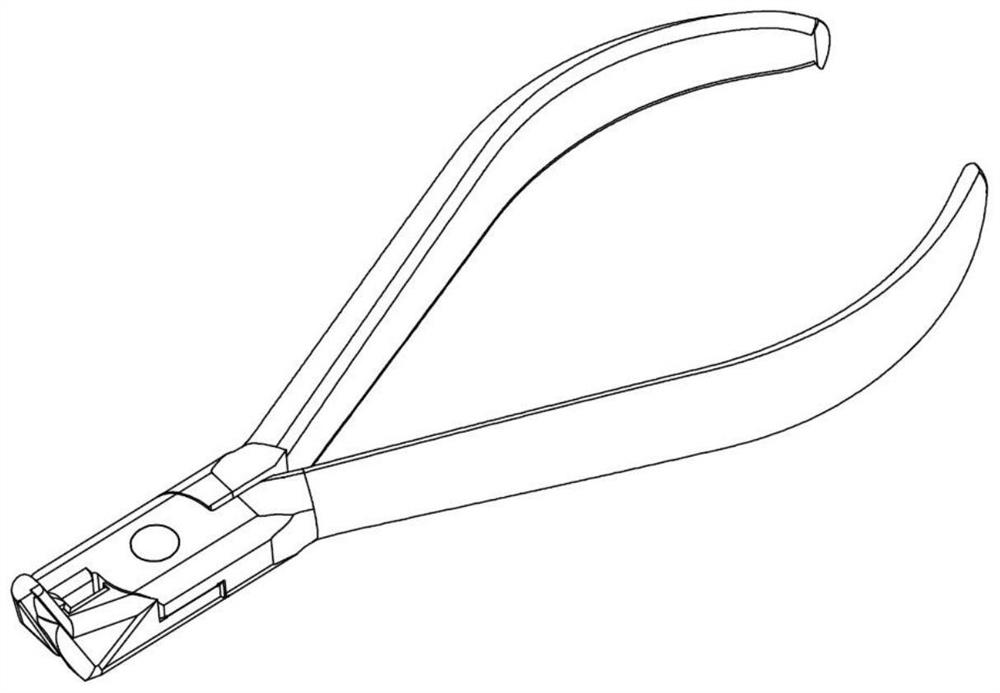

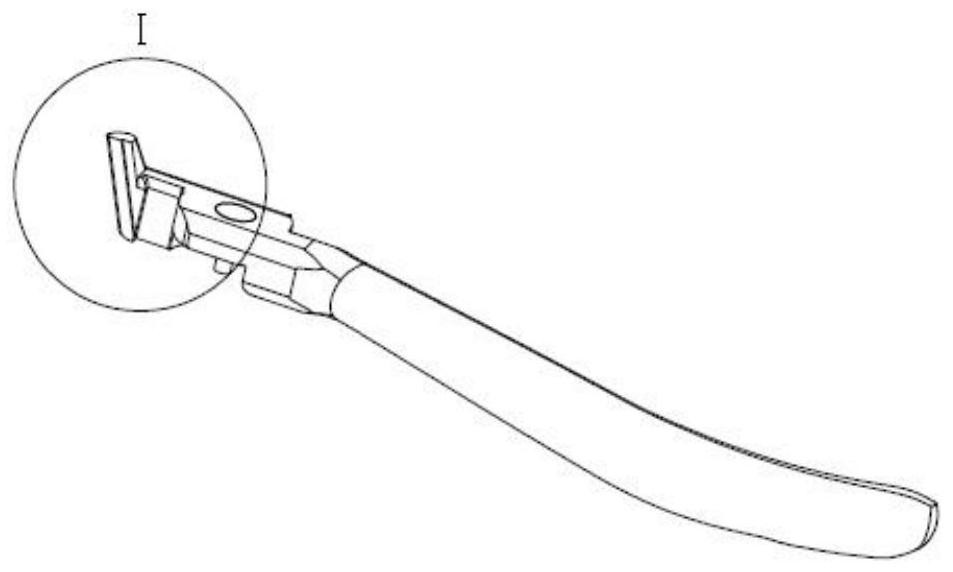

Titanium alloy orthodontic forceps and preparation method thereof

A titanium alloy and orthodontic technology, applied in the field of titanium alloy orthodontic pliers and its preparation, can solve the problems of poor welding performance, easy peeling off of PVD coating, poor corrosion resistance of the base material of the pliers beak, etc., to ensure fluidity and maintenance Formability, less EDM discharge machining amount, and high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The selected titanium alloy material composition of titanium alloy orthodontic pliers in the present invention is: titanium (surplus), aluminum (3%), vanadium (8%), molybdenum (4%), zirconium (4%), niobium (1%) %), nickel (2%), chromium (6%). Use -200 mesh gas atomized spherical titanium alloy master alloy powder, the composition is titanium (balance), aluminum (9%), vanadium (24%), molybdenum (12%), zirconium (12%), niobium (3%) ), nickel (6%), chromium (18%); another -400 mesh hydrogenated dehydrogenation pure titanium powder is selected; the two are mixed uniformly by double cone mixer at a weight ratio of 1:2; the powder obtained by mixing is mixed with viscous Kneading agent is mixed and made feed, and binder composition is by weight 32% of paraffin wax, palm wax 8%, polyethylene wax 15%, polyethylene 22%, polypropylene 15%, EVA6%, stearic acid 2% , The weight ratio of powder and binder is 92.1%: 7.9%. The feeding material is shaped by an injection molding machin...

Embodiment 2

[0029] The selected titanium alloy material composition is: titanium (balance), aluminum (5%), vanadium (5%), molybdenum (5%), niobium (2%), nickel (1%), chromium (3%) . Use -200 mesh gas atomized spherical titanium alloy master alloy powder, the composition is titanium (balance), aluminum (15%), vanadium (15%), molybdenum (15%), niobium (6%), nickel (3%) ), chromium (9%); another -400 mesh hydrogenation dehydrogenation pure titanium powder is selected; the two are mixed in a double-cone mixer at a weight ratio of 1:2; the powder obtained by mixing is mixed with a binder to make Feed, the binder composition is by weight 40% paraffin wax, palm wax 10%, polyethylene wax 5%, polyethylene 10%, polypropylene 25%, EVA8%, stearic acid 2%, powder and binder The weight ratio is 92.3%:7.7%. The feeding material is formed at a temperature of 160°C by an injection molding machine and a mold designed for the required orthodontic jaws. After forming, it enters a sintering furnace and is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com