A kind of environment-friendly epoxy resin coating, environment-friendly coil material and preparation method thereof

A technology of epoxy resin coating and epoxy resin, applied in epoxy resin coating, chemical instruments and methods, synthetic resin layered products, etc. The effect of utilization, low density and good warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

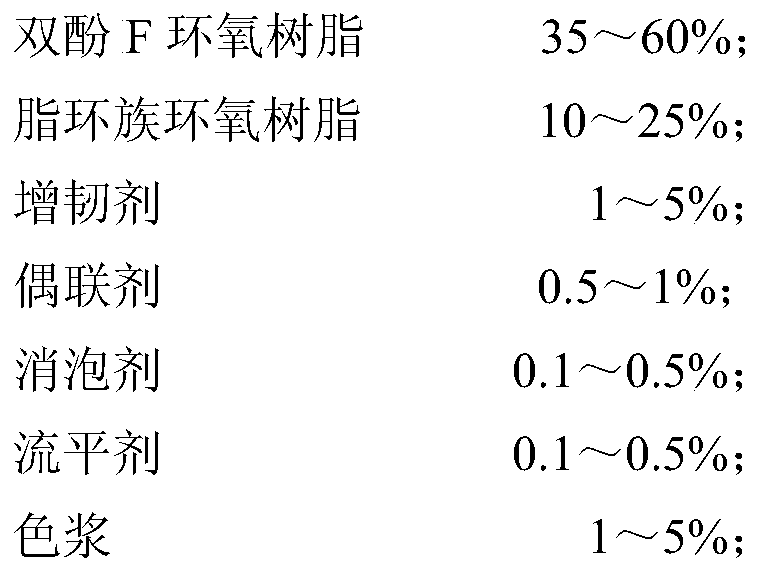

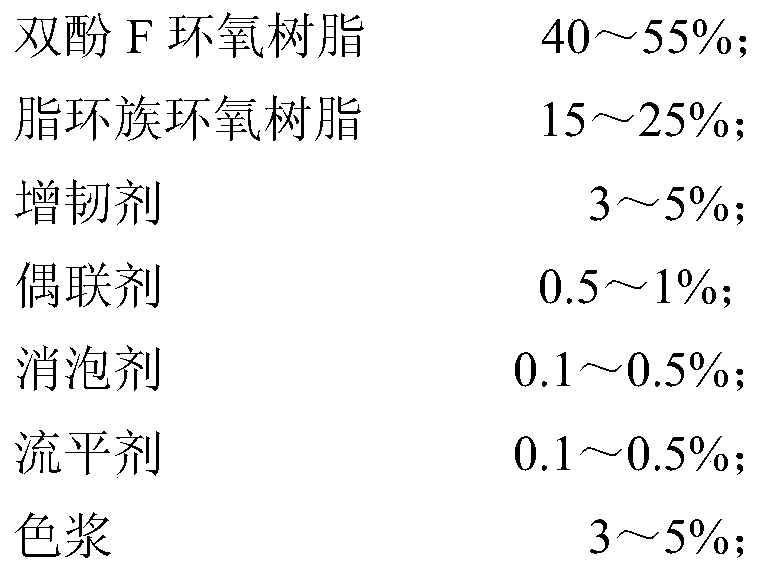

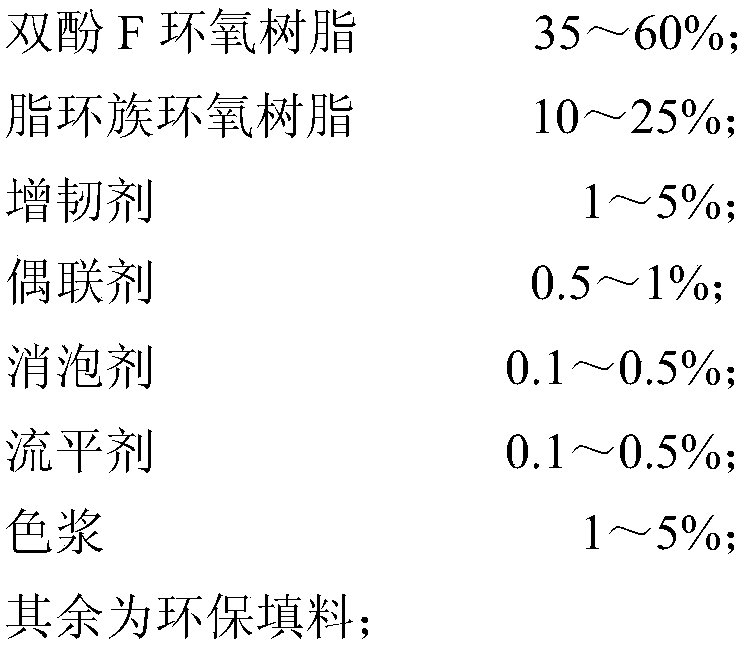

[0049] 1. Preparation of environmentally friendly epoxy resin coating

[0050] Separately prepare two components of epoxy resin, among which,

[0051] Preparation of component A: 55 parts of bisphenol F epoxy resin YD170 with an epoxy equivalent of 170g / eq, 10 parts of alicyclic epoxy resin CELLOXIDE 2021P with a viscosity of 300Cps and an epoxy equivalent of 130g / eq, 5 parts Toughening agent ZR41, stir for 30 minutes at a speed of 600r / min, then add 0.5 parts of coupling agent KH550, 0.3 parts of defoamer ST550, 0.2 parts of leveling agent ST336F, 4 parts of color paste, 25 parts 250 mesh wood flour, stirred for 30 minutes under the condition of 900r / min, to obtain component A.

[0052] Preparation of component B: Place 70 parts of curing agent DY230, 20 parts of curing agent 1,3BAC in the reactor, add 5 parts of epoxy resin E44, react at 60℃ for 1 hour, cool to below 35℃, add 5 Parts curing accelerator DMP-30 to get B component.

[0053] The components A and B are mixed in a weigh...

Embodiment 2

[0062] 1. Preparation of environmentally friendly epoxy resin coating

[0063] Separately prepare two components of epoxy resin, among which,

[0064] Preparation of component A: 50 parts of bisphenol F epoxy resin YD170 with an epoxy equivalent of 170g / eq, 20 parts of alicyclic epoxy resin CELLOXIDE 2081 with a viscosity of 340Cps and an epoxy equivalent of 200g / eq, 3 parts Toughening agent ZR41, stir for 30 minutes at a speed of 600r / min, then add 0.5 parts of coupling agent KH550, 0.2 parts of defoamer ST550, 0.3 parts of leveling agent ST336F, 3 parts of color paste, 13 parts 300 mesh wood flour and 10 parts 600 mesh bamboo flour were stirred for 25 minutes at a rotation speed of 1000 r / min to obtain component A.

[0065] Preparation of component B: put 40 parts of curing agent DY230, 50 parts of curing agent 1,3BAC in the reaction kettle, add 5 parts of epoxy resin E44, react at 60℃ for 1 hour, cool the temperature to below 35℃, add 5 Parts curing accelerator DMP-30 to get B c...

Embodiment 3

[0075] 1. Preparation of environmentally friendly epoxy resin coating

[0076] Separately prepare two components of epoxy resin, among which,

[0077] The preparation of A component: 50 parts of bisphenol F epoxy resin YD170 with epoxy equivalent of 175g / eq, 20 parts of alicyclic epoxy resin CELLOXIDE 2021P with viscosity of 350Cps and epoxy equivalent of 135g / eq, 3 parts Toughening agent ZR41, stir for 30 minutes at a speed of 600r / min, then add 0.5 parts of coupling agent KH550, 0.2 parts of defoamer ST550, 0.3 parts of leveling agent ST336F, 3 parts of color paste, 10 parts 600-mesh nut shell powder, 10 parts of 800-mesh bamboo powder, 3 parts of 200-mesh cork particles, stirred for 20 minutes at a rotation speed of 1000 r / min, to obtain component A.

[0078] Preparation of component B: put 40 parts of curing agent DY230, 50 parts of curing agent 1,3BAC in the reaction kettle, add 5 parts of epoxy resin E44, react at 60℃ for 1 hour, cool the temperature to below 35℃, add 5 Parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com