Light glass fiber reinforced ABS composite board material and board preparation method

A composite sheet and ABS plastic technology, applied in the field of polymer composite materials, can solve the problems of high cost of supercritical equipment and unfavorable large-scale promotion, and achieve the effects of uniform cells, short production cycle and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

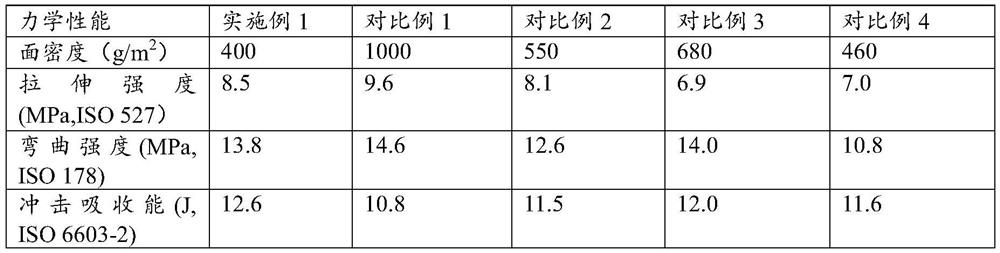

Examples

preparation example Construction

[0022] In one embodiment, a method for preparing a lightweight glass fiber reinforced ABS composite sheet is also provided, including:

[0023] Mix chopped glass fiber, ABS plastic powder, expandable microspheres and additives according to the above-mentioned parts by weight, add them to the stirring container, and prepare a suspension system with water as the dispersion medium. The rotation speed is 500-3000r / min, fully Stir for 10-40min, mix well;

[0024] The dispersed suspension system is filtered by suction, and the mixed material after suction filtration is dehydrated and dried at a drying temperature of 80-150°C for 60-120 minutes;

[0025] Place the dried material in a hot-pressing device at a temperature of 160-200°C for 1-10 minutes, and cut it after cooling to obtain a preformed GF / ABS plate;

[0026] Place the newly formed GF / ABS sheet in an oven for foaming at a temperature of 200-260°C and a time of 0.5-6 minutes to obtain a lightweight glass fiber reinforced AB...

Embodiment 1

[0029]The lightweight glass fiber reinforced ABS composite sheet material includes the following components by mass fraction: 30 parts of chopped glass fiber of 6 mm, 70 parts of ABS powder with an average particle size of 80-120 μm, 5 parts of expandable microspheres, dodecyl sulfate 1 part sodium, 1 part anionic polyacrylamide. The foaming temperature of the expandable microspheres in this embodiment is 210-230° C., the initiation temperature is 180-190° C., and the particle size is 10-30 μm.

[0030] The plate preparation method of lightweight glass fiber reinforced ABS composite plate comprises the following steps:

[0031] 1) Mix chopped glass fiber, ABS powder, microspheres and additives according to the above parts by weight, add them to the stirring container, and make a suspension system with water as the dispersion medium. Uniform;

[0032] 2) After the dispersed suspension system is filtered by suction, the mixed material after suction filtration is dehydrated and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com