Combined grooved pulley mechanism

A combination of groove and sheave technology, applied in mechanical equipment, belts/chains/gears, transmission devices, etc., can solve the problems of large space occupation, large rigid impact, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

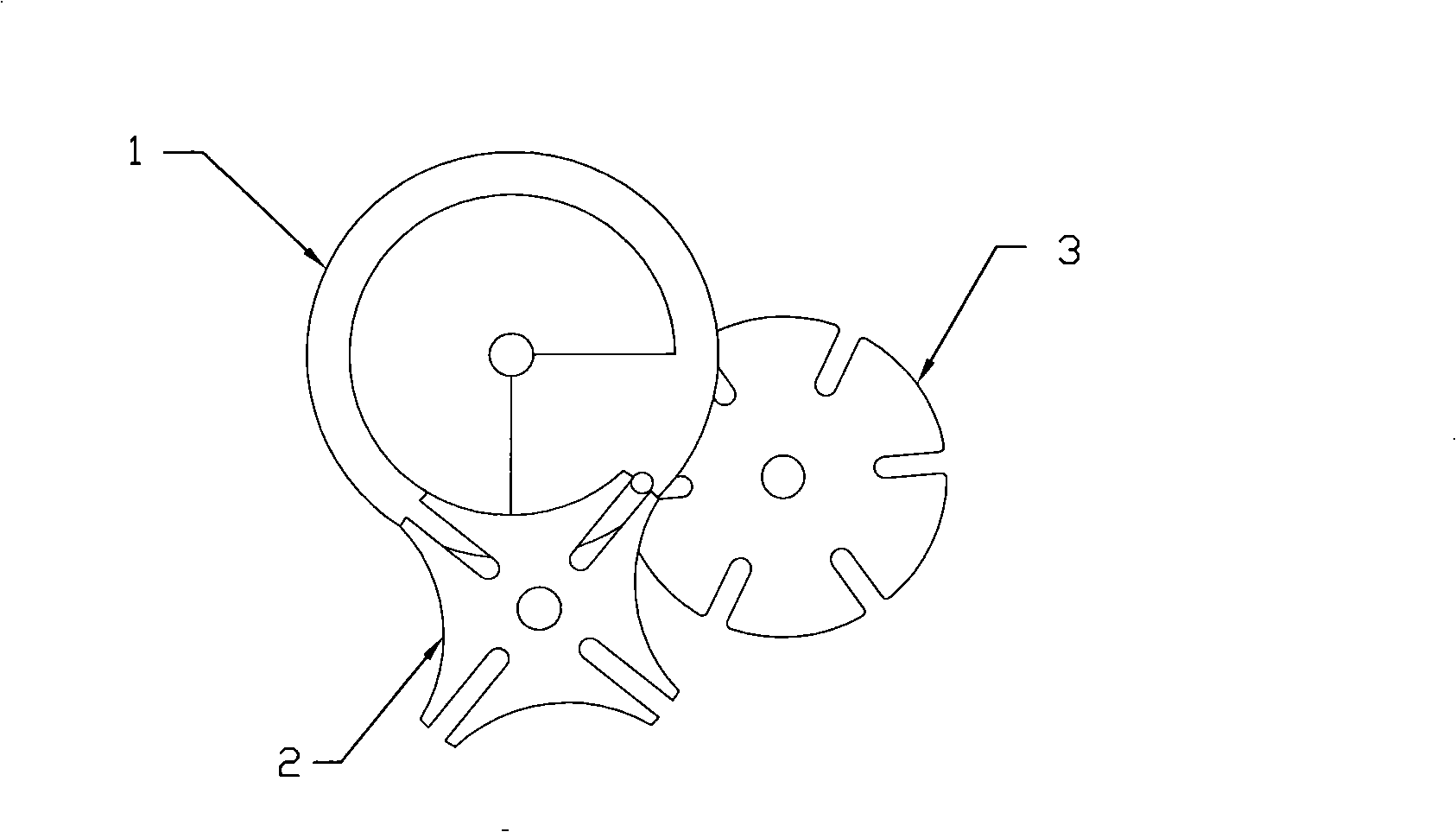

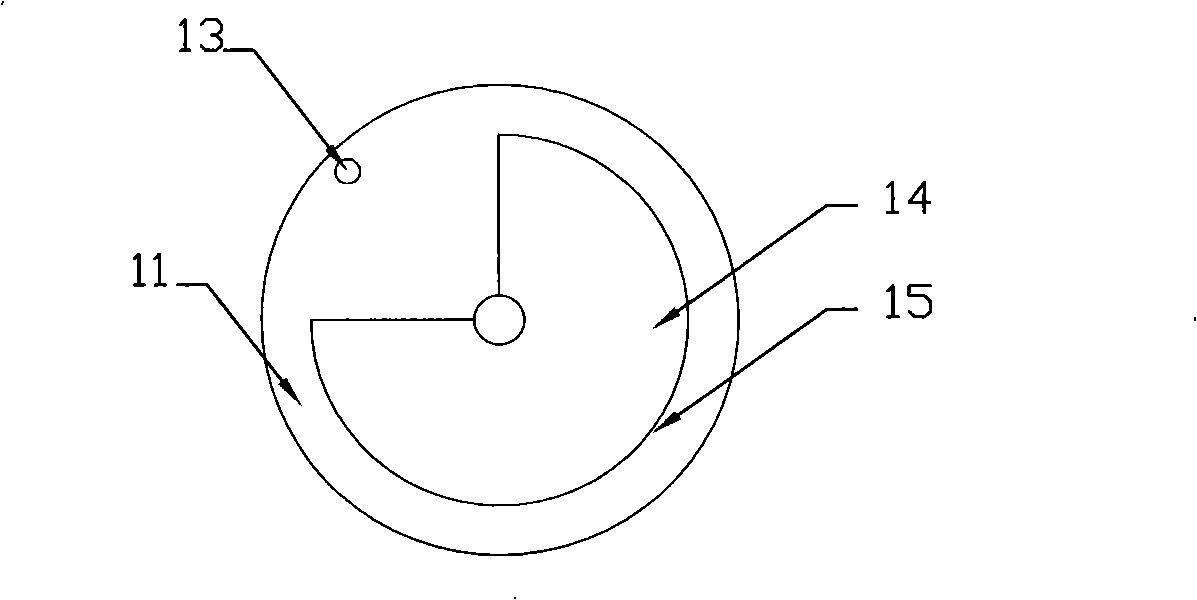

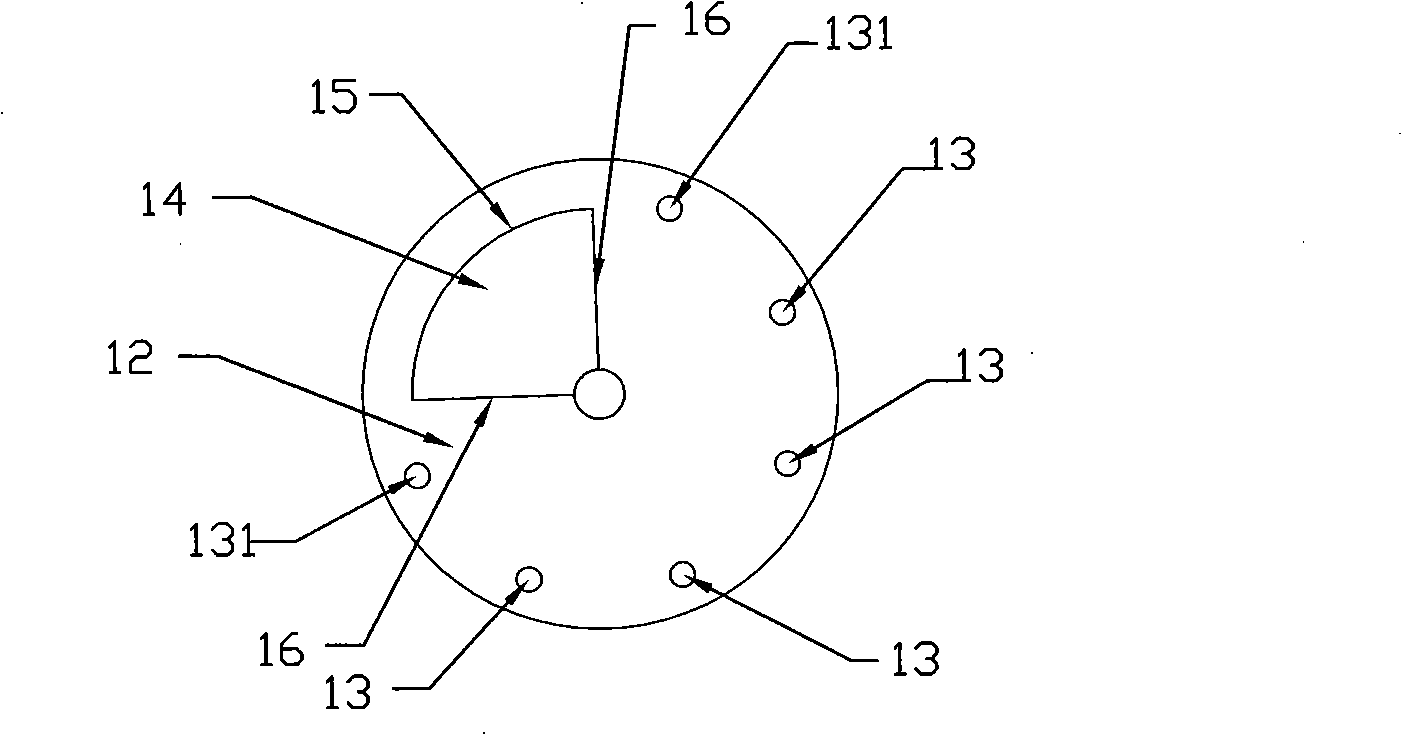

[0015] Referring to the attached picture:

[0016] Realize the combined sheave mechanism of the present invention, including a driving dial 1 and a first sheave 2, the circular pins 13 for transmitting power and the locking arcs for locking the sheave are evenly distributed on the front face 11 of the dial Platform 14; the distance from the center of circle of the round pin 13 to the center of the dial is greater than or equal to the sum of the radius of the round pin 13 and the radius of the locking arc protrusion 14; the outer edge 15 of the locking arc protrusion It has a circular profile, and the opening angle of the locking arc protrusion 14 is the inter-groove angle formed by the centerlines of two adjacent straight grooves on the sheave 2 plus 180 degrees. Straight grooves 21 are evenly distributed on the first sheave 2, and the end of the straight grooves 21 is a semicircular arc 23 with the groove width as the diameter. Cooperate; the distribution between the two str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com