Energy-saving type automatic compensation valve core multi-functional pilot solenoid valve

A pilot solenoid valve and automatic compensation technology, which is applied in the mechanical field, can solve the problems of narrow adaptability to medium and working conditions, and the decline of the closing performance of the diaphragm solenoid valve, and achieve the effects of reliable sealing, reduced rigid impact, and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

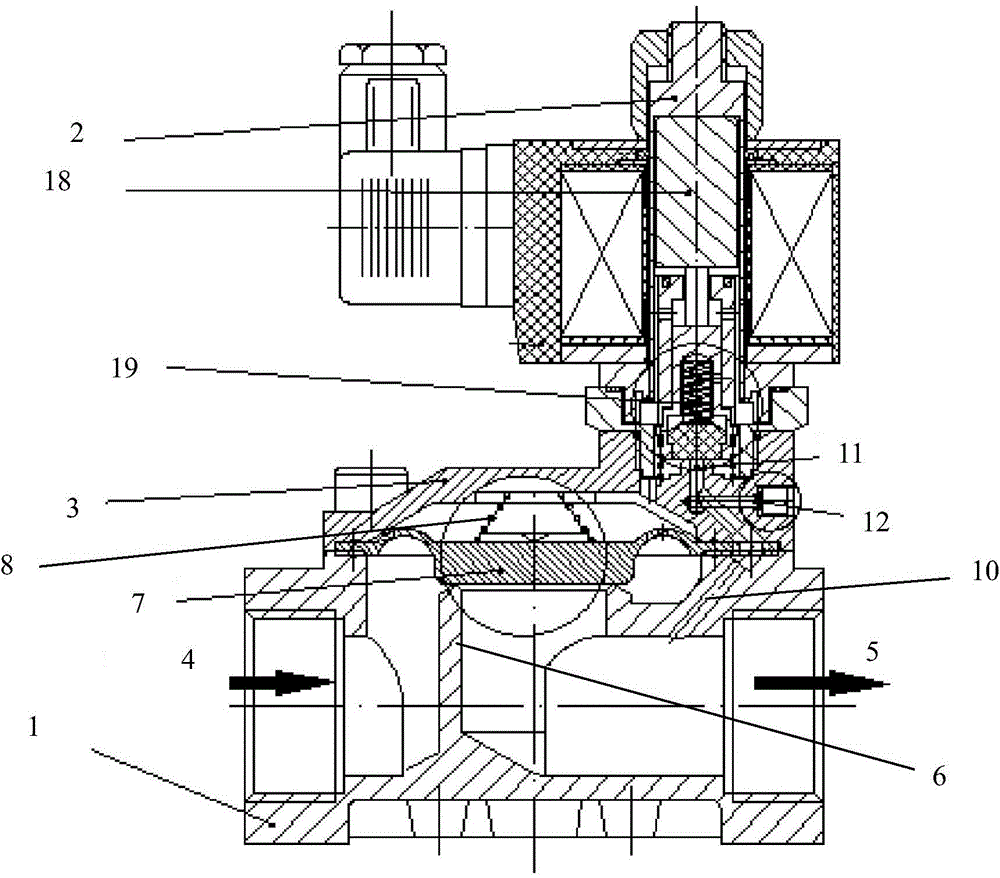

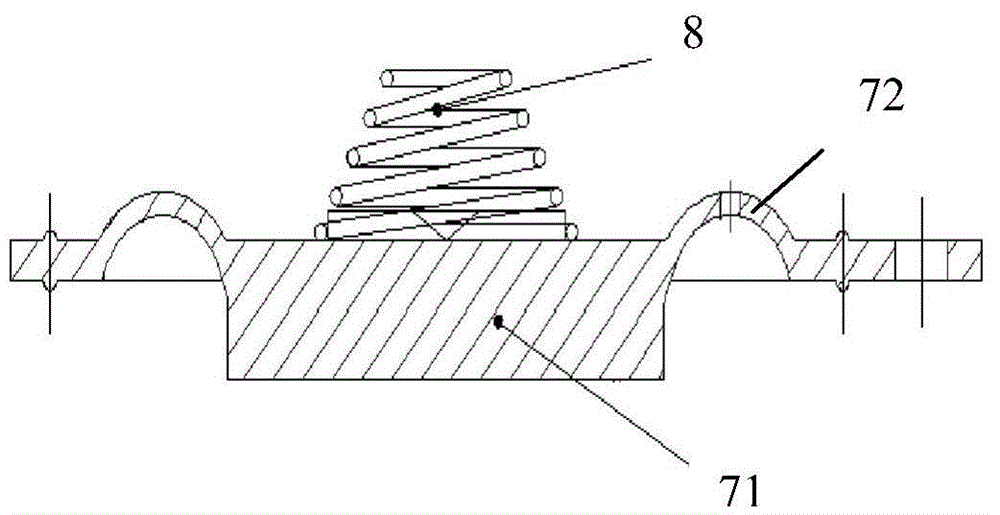

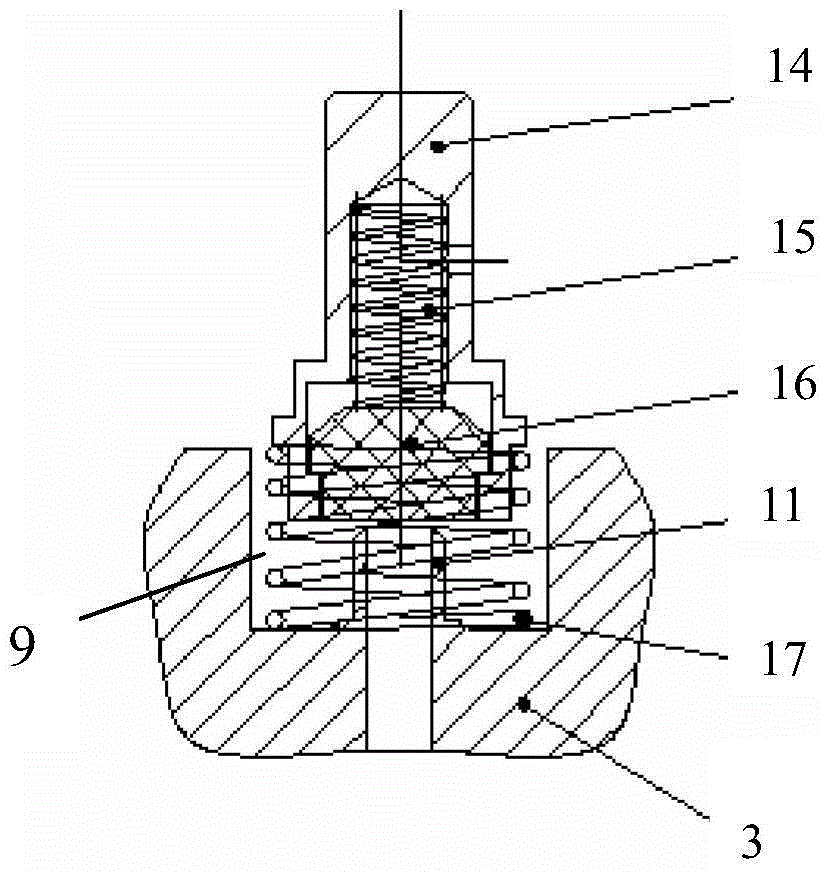

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, an energy-saving automatic compensating spool multifunctional pilot solenoid valve of the present invention includes a valve body 1 and an electromagnetic drive mechanism 2, and a valve cover 3 is fixedly arranged on the valve body 1, and the electromagnetic drive The mechanism 2 is fixedly connected with the valve cover 3, the valve body 1 includes a fluid inlet 4 and a fluid outlet 5, a valve cavity is arranged between the fluid inlet 4 and the fluid outlet 5, and the valve cavity A valve seat 6 is arranged inside, and the valve seat 6 is connected to the inner wall of the valve cavity. The valve seat 6 includes a flow channel, and the flow channel is connected with the fluid outlet 5, wherein the valve cavity A corrugated diaphragm 7 is arranged inside, and the corrugated diaphragm 7 includes a main diaphragm 71, and the periphery of the main diaphragm 71 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com