Ultra-high pressure sea water safety valve

A technology of ultra-high pressure and safety valves, which is applied in the field of safety valves, can solve problems such as the limitation of the scope of application, and achieve the effect of unlimited scope of application and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

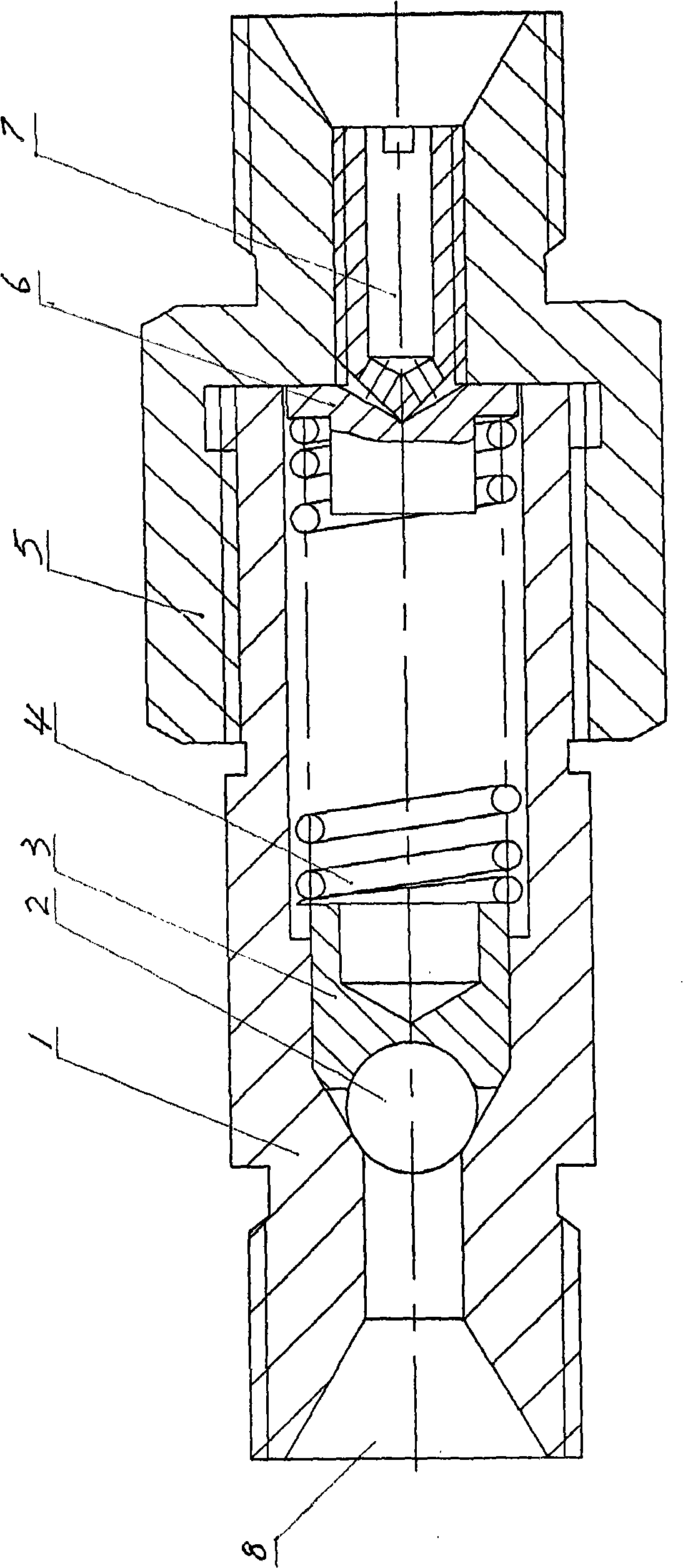

[0009] As shown in the drawings, the ultra-high pressure seawater safety valve of the present invention includes a valve body 1, which is tubular, with a water inlet 8 at one end and a gland 5 fixed at the other end. The end of the gland 5 connected to the valve body 1 is respectively processed with an internal thread and an external thread, and the gland 5 is fixed with the valve body by means of the internal thread and the external thread.

[0010] The center of the cover bottom of the gland 5 is processed with a screw hole, and the screw hole is equipped with a pressure regulating screw 7. Between the water inlet 8 and the gland 5, a valve flap 3, a spring 4 and a spring seat 6 are sequentially arranged. The inner diameter of the water inlet 8 is smaller than the diameter of the inner cavity of the valve body 1, and the connection between the water inlet 8 and the inner cavity of the valve body 1 is processed into a conical surface, and a steel ball 2 is arranged between th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap