Slide rail verticality testing apparatus

A detection device and verticality technology, applied in measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve problems such as poor applicability, increased use costs, and reduced detection device accuracy, and achieve strong applicability and save enterprises. Cost, good looks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

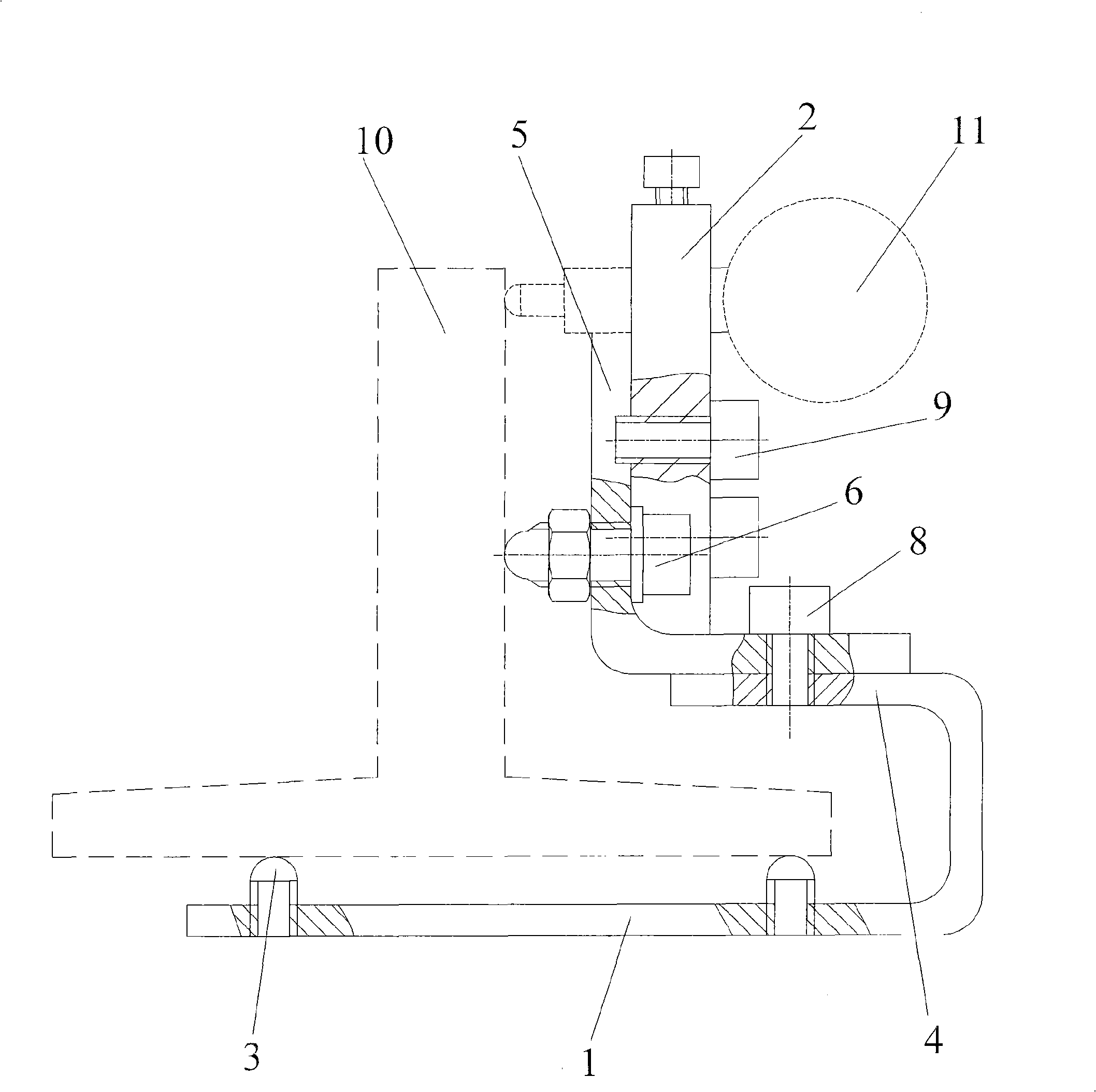

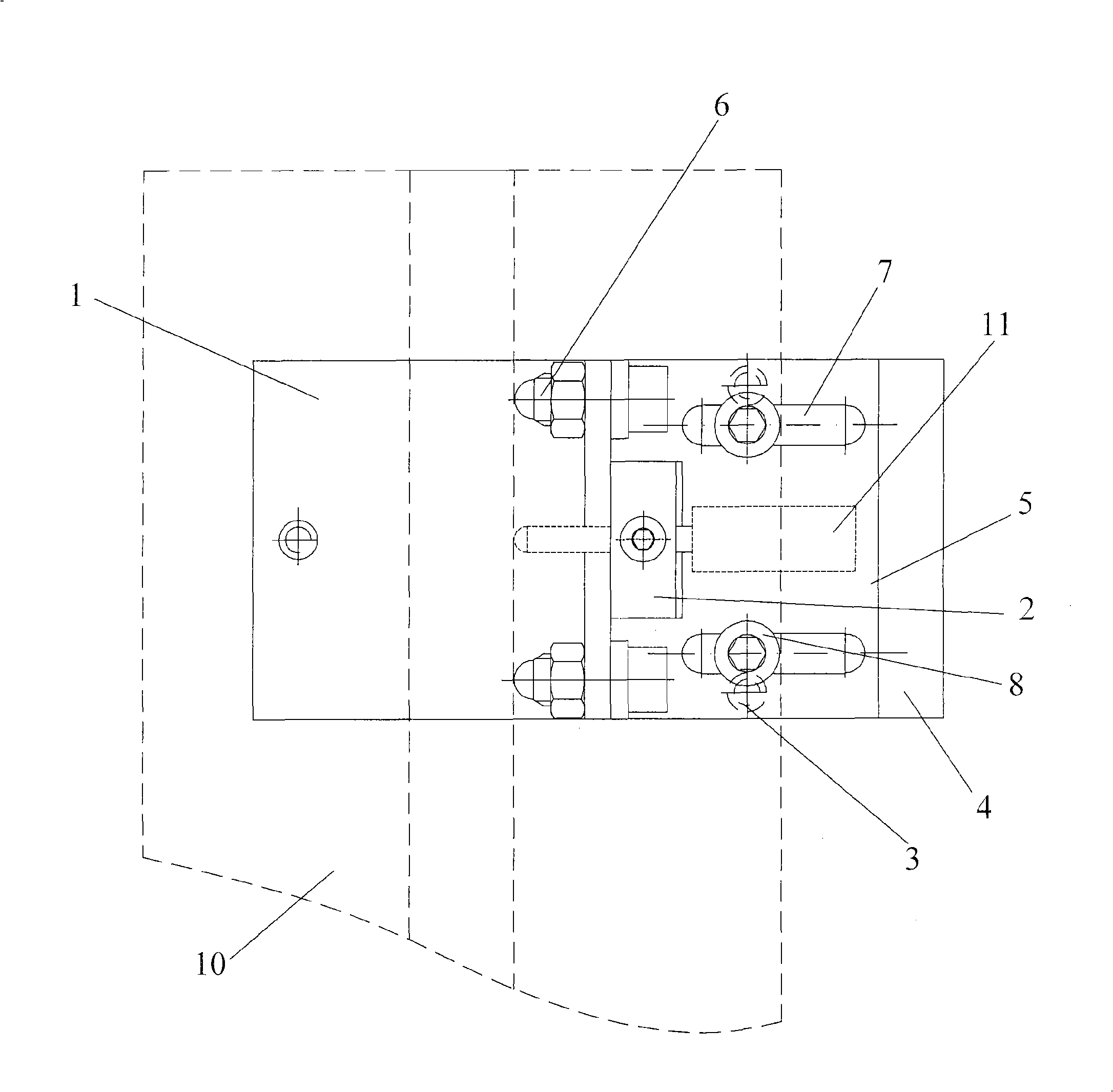

[0013] Example: such as figure 1 and figure 2 As shown, a guide rail verticality detection device includes a base plate 1 and a dial indicator mounting plate 2 vertically arranged with the base plate 1. The base plate 1 is provided with positioning beads 3, and the bottom surface of the T-shaped guide rail 10 is placed on three On the positioning bead 3 forming a triangle, one end of the bottom plate 1 extends upwards and is folded inward to form an upper plate 4 parallel to the bottom plate 1. The detection device also includes a moving plate 5 with an L-shaped cross section. The lower part of the moving plate 5 is Fixed with the upper plate 4, the dial gauge mounting plate 2 is fixed to the side of the moving plate 5, and the side of the moving plate 5 is provided with a side positioning piece 6. When testing, the hemispherical top of the side positioning piece 6 is just against the On the side working surface of the T-shaped guide rail 10 , the measuring head of the dial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com