Exterior parameter self-calibration method for camera with rotating stereovision

A stereo vision, self-calibration technology, applied in image data processing, image analysis, instruments, etc., can solve the problem of camera extrinsic parameters camera extrinsic parameter calibration loss of meaning and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings.

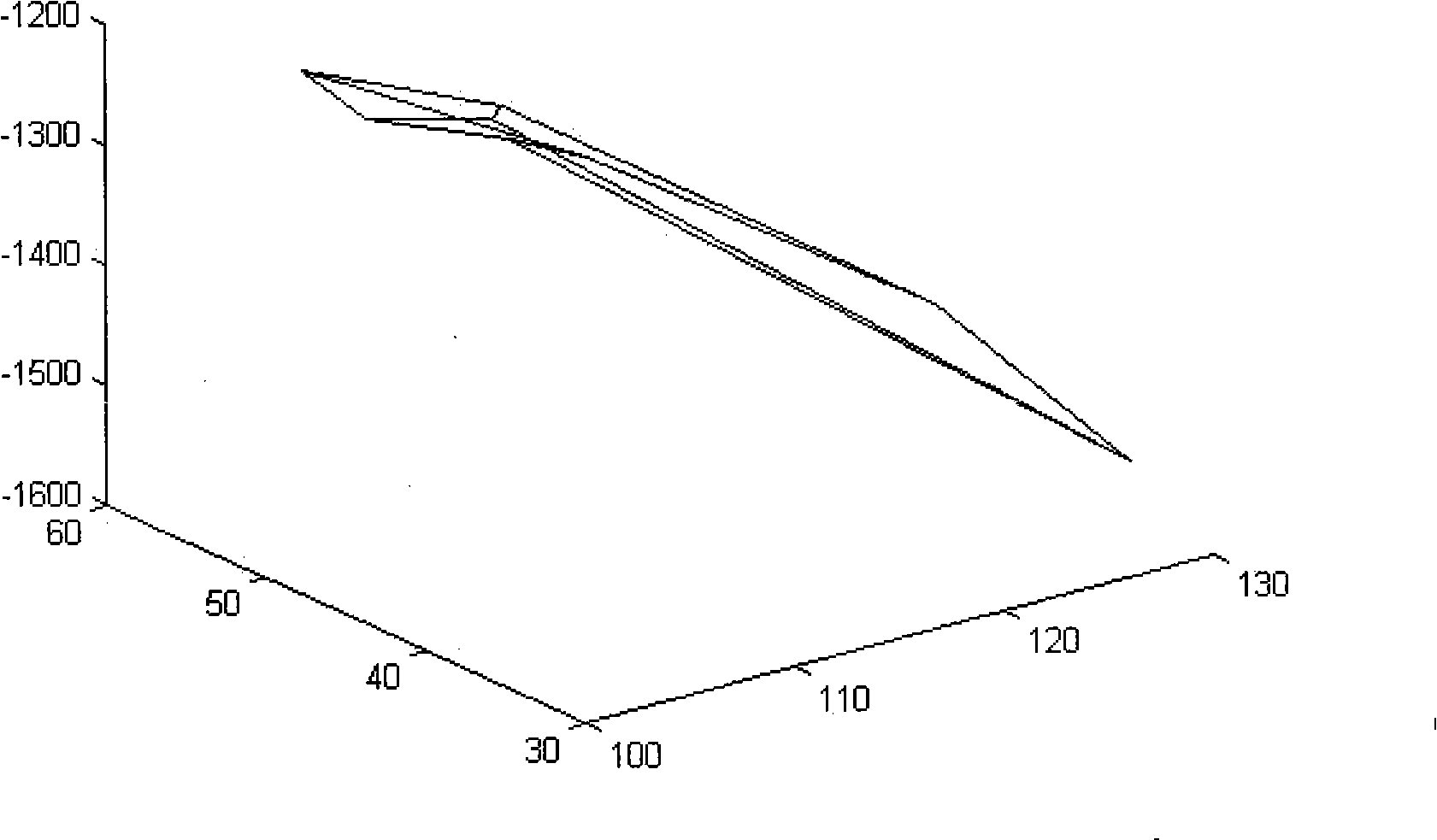

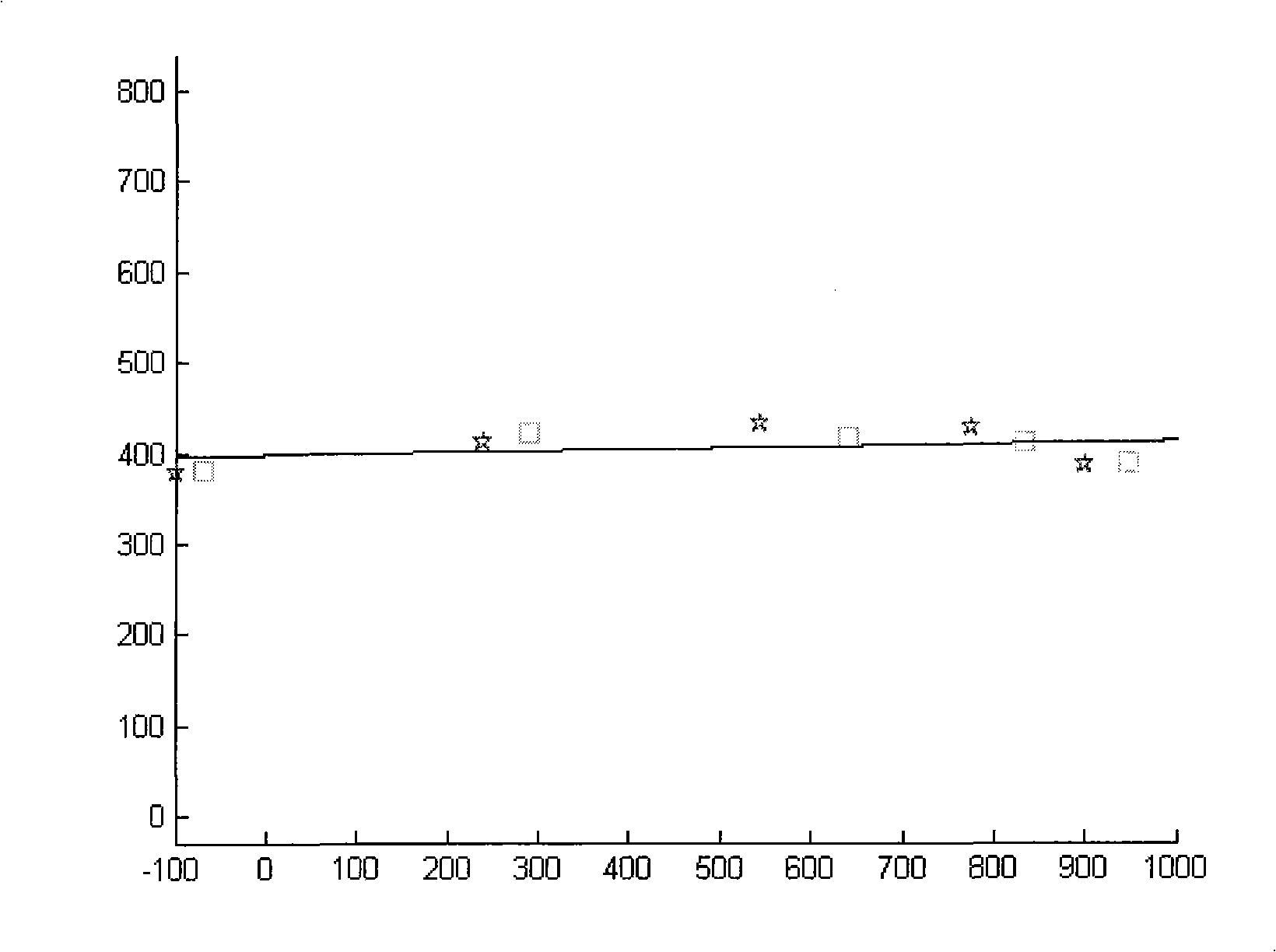

[0069] refer to Figure 1 to Figure 4 , a self-calibration method for external parameters of rotational stereo vision, the self-calibration method comprises the following steps:

[0070] 1) Manual calibration of the camera to obtain the internal parameters of the camera:

[0071] A coordinate plane of the world coordinate system is set to coincide with the plane of the calibration plate, and the coordinate axis perpendicular to this coordinate plane is perpendicular to the plane of the calibration plate. Here, the coordinate plane that coincides with the calibration plate plane is the XOY plane. Calibration board as appendix figure 1 In this way, the world coordinates of the center point on the calibration plate can be obtained. By moving the calibration plate in the Z direction, the world coordinates of multiple points in space that are not on the same plane can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com