Movable contact element and switch using the same

A technology of moving contacts and contact bodies, applied in the direction of electric switches, electronic switches, electrical components, etc., which can solve the problems of increased number of parts, high cost of movable contact body 102 and switch 150, complex structure of switch 150, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

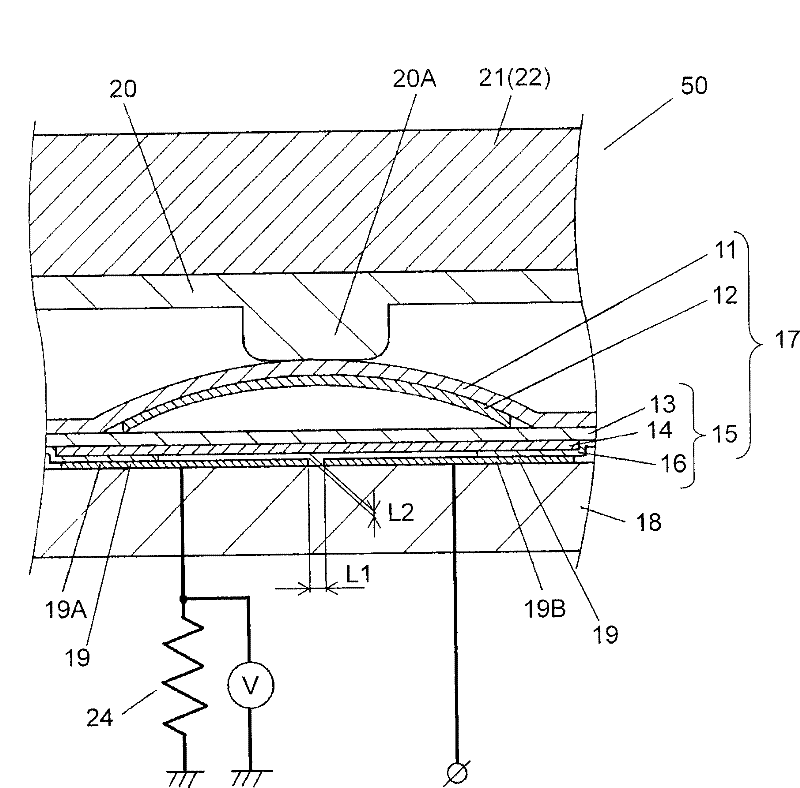

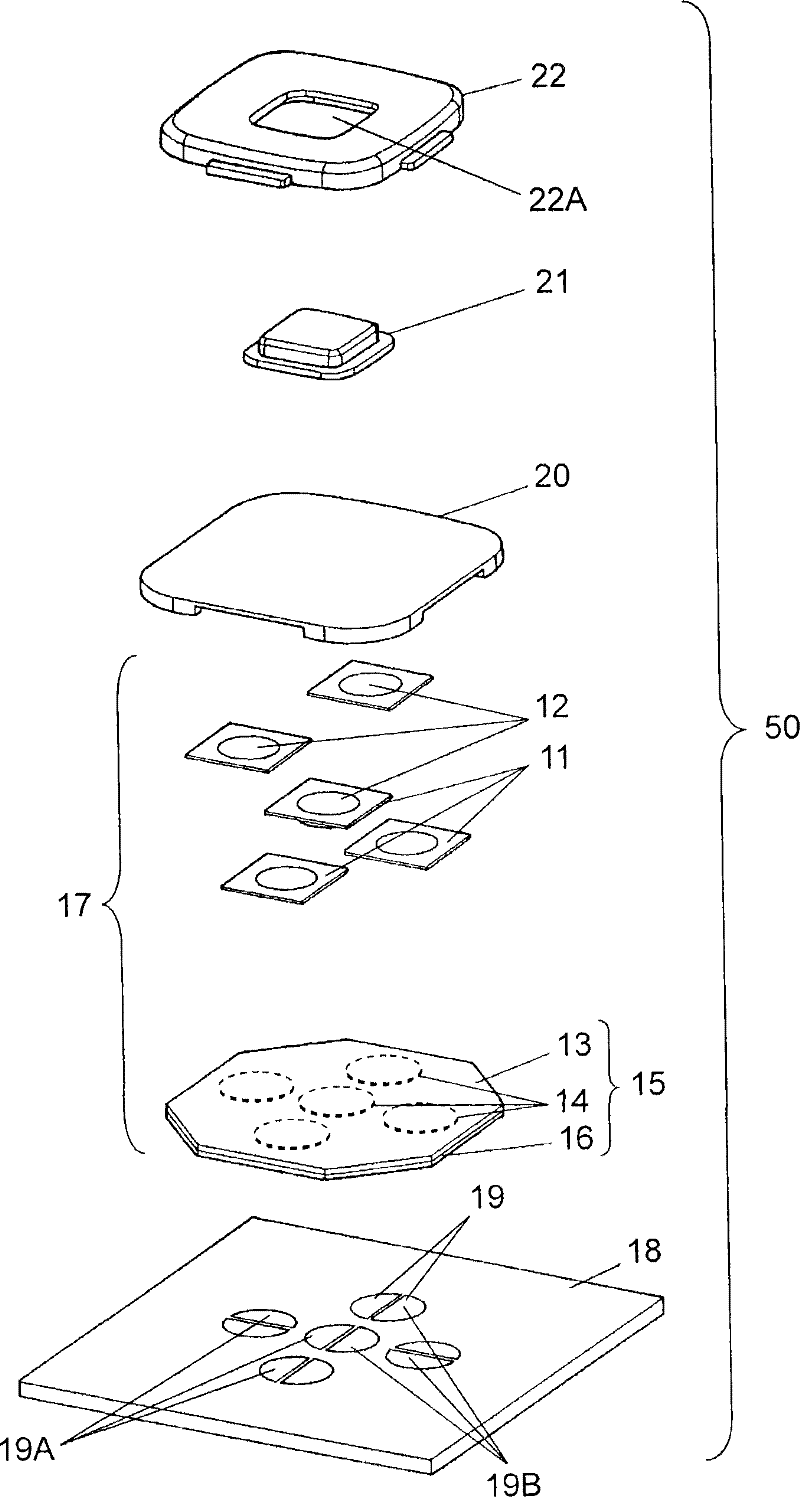

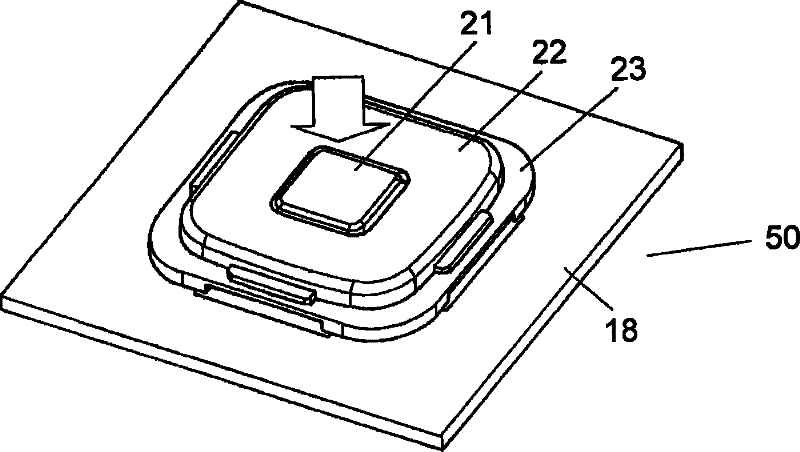

[0040] Below, use figure 1 ~ Fig. 8, Embodiment 1 of the present invention will be described.

[0041] figure 1 It is a sectional view of the switch 50 according to Embodiment 1 of the present invention. figure 2 It is an exploded perspective view of the switch 50 . Figure 3A and Figure 3B is a perspective view of the switch 50 . Figure 4 is a cross-sectional view of a pressure-sensitive conductive plate 15 (hereinafter referred to as a sheet 15 ) employed in the switch 50 . Figure 5 It is a cross-sectional view when the switch 50 is pressed. Figure 6 is a characteristic diagram of the switch 50. Figure 7A It is a plan view of the display screen 30 of an electronic device (not shown) equipped with the switch 50 . Figure 7B It is a plan view of the display screen 30 of another mode of the electronic device equipped with the switch 50 . Figure 8A is a plan view of the fixed contact 19 used in the switch 50 . Figure 8B It is a plan view of another fixed conta...

Embodiment approach 2

[0071] Embodiment 2 of the present invention will be described below using the drawings. It should be noted that the same reference numerals are assigned to the same configuration as that of Embodiment 1, and detailed description thereof will be omitted.

[0072] Figure 9 It is a sectional view of switch 50A according to Embodiment 2 of the present invention. Figure 10 It is a plan view of the fixed contact 29 used in the switch 50A. Figure 11 is a characteristic diagram of switch 50A.

[0073] Such as Figure 9 and Figure 10 As shown, in the switch 50A, the movable contact 12 is pasted on the lower surface of the cover plate 11 . In addition, in the switch 50A, the cover plate 11 is pasted on the upper surface of the pressure-sensitive conductive plate 15 . These structures have the same structure as that of the first embodiment. In addition, in movable contact body 17A and switch 50A according to Embodiment 2, the outer periphery of pressure-sensitive conductive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com