Vertical roller mill with side shifting roll-changer

A vertical roll mill and replacement technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of increasing the amount of maintenance spare parts, the consumption of spare parts, the cumbersome operation of changing rolls in the rolling mill, and the easy damage of the connecting device and other problems, to achieve the effect of light weight, convenient maintenance and repair, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

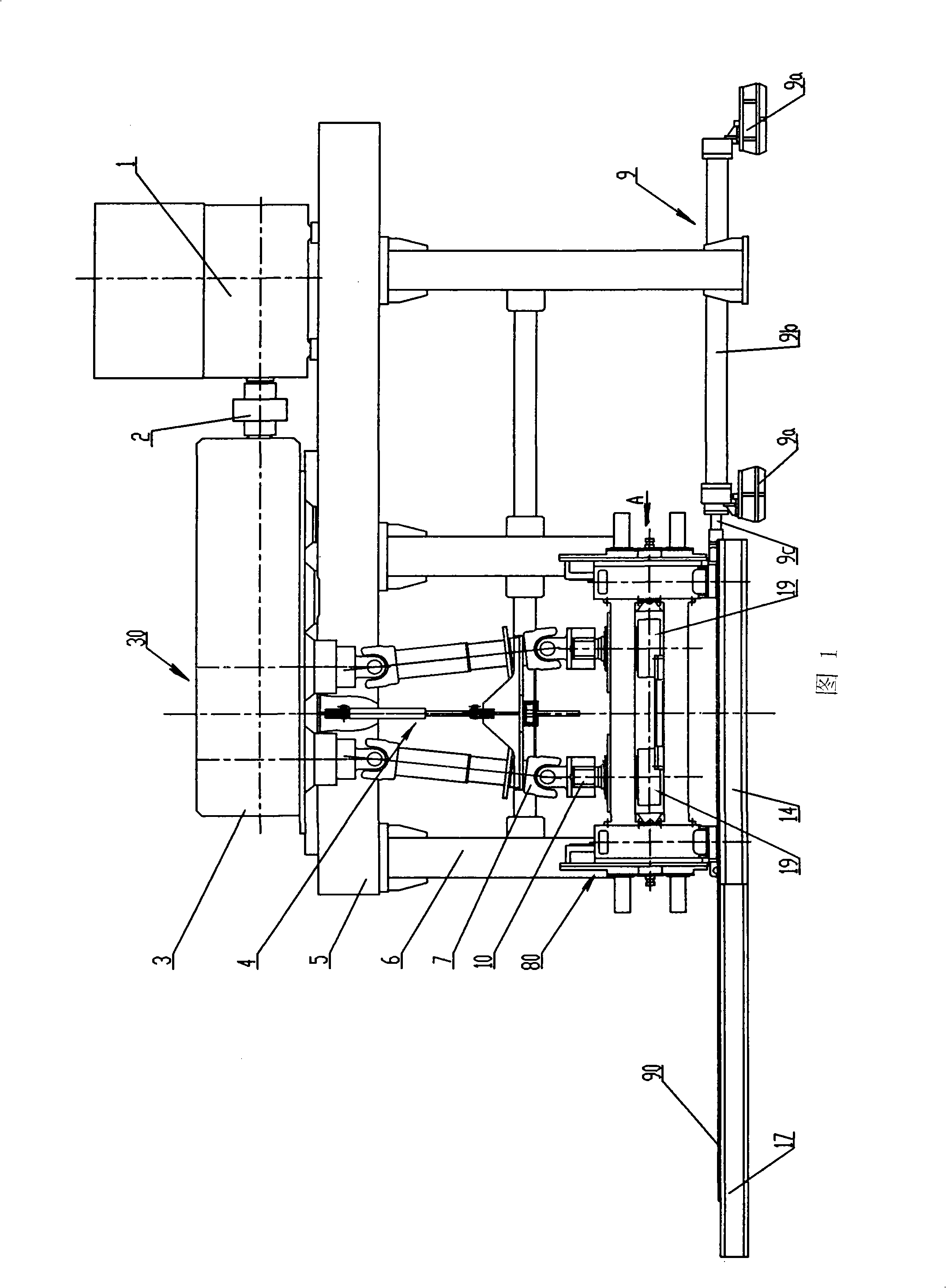

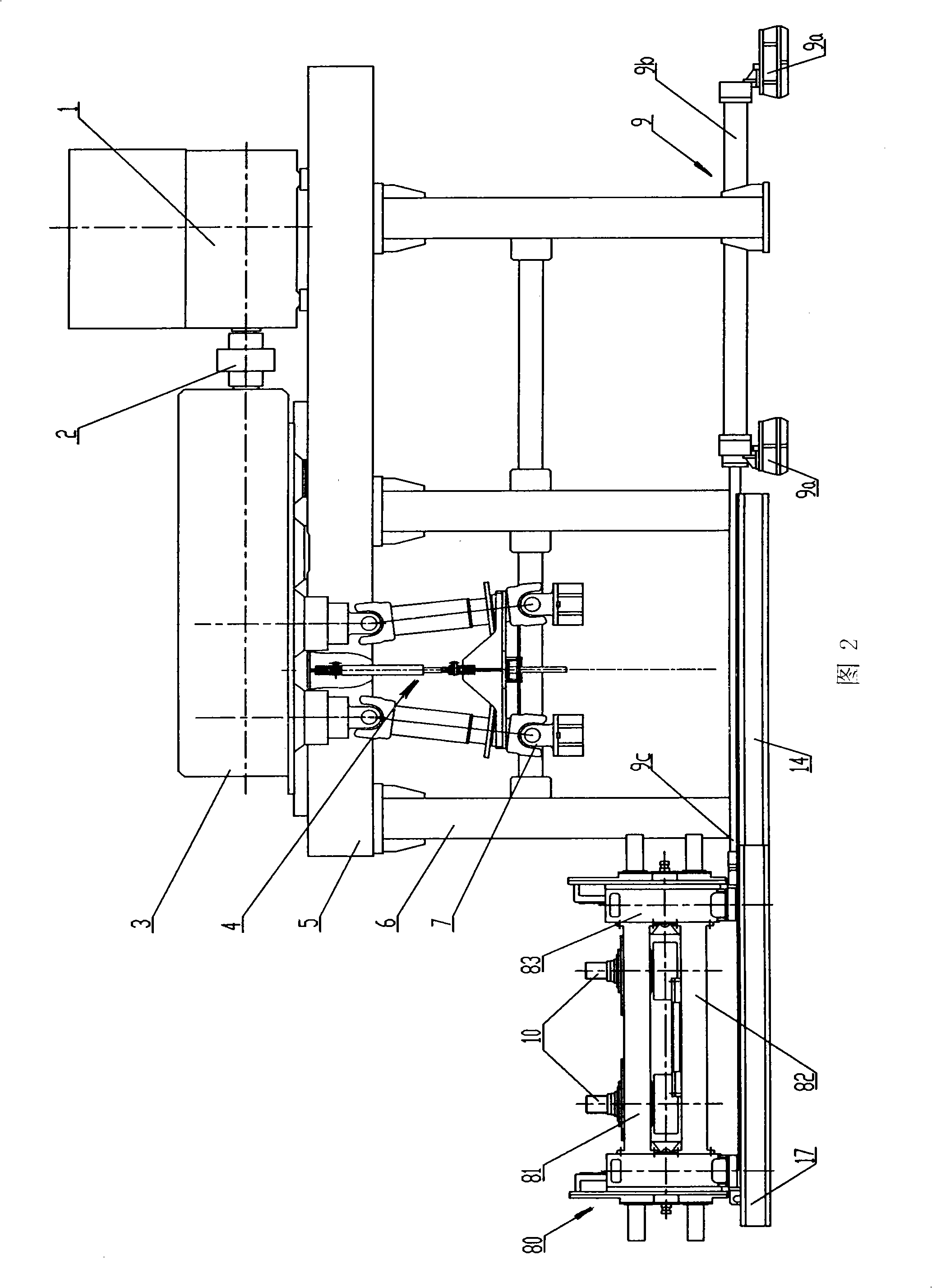

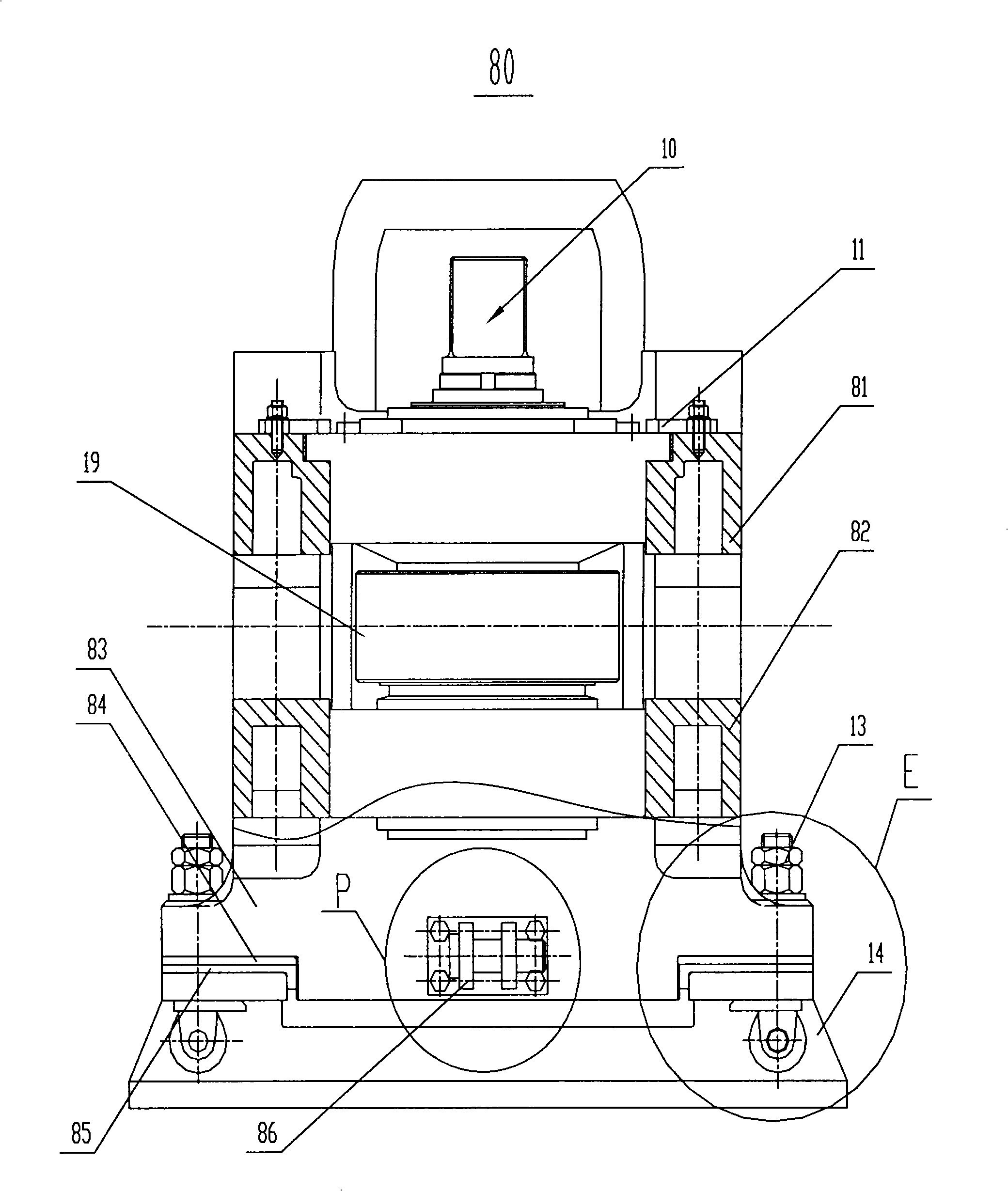

[0031] As shown in Fig. 1 and Fig. 2, the present invention provides a vertical rolling mill with a side shifting roll changing device. The vertical rolling mill includes: a transmission platform 5 supported by a column 6, a power output part 30, a The rolling mill body 80 of the series 10.

[0032] The vertical rolling mill also includes a push roll part 9 and a cardan shaft lifting part 4 that push the rolling mill body 80 to move horizontally.

[0033] The roll pushing part 9 is arranged on one side of the rolling mill body 80 , and a roll changing platform 17 is arranged on the other side of the rolling mill body 80 . A lining plate 90 is installed on the roll changing platform 17 , and the lining plate 90 is convenient for the roll pushing part 9 to smoothly push the rolling mill body 80 on the roll changing platform 17 .

[0034] The cardan shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com