Complete interchanging quick fix tower section K lever welding fixture

A technology of welding tooling and glyphs, which is applied in the field of welding tooling for fully interchangeable and fast-installed tower sections with K-shaped rods, can solve the problems of large dimensional errors of tower sections, low work efficiency, and difficult transportation, so as to reduce deformation out-of-tolerance and improve work efficiency. Efficiency, the effect of solving transportation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

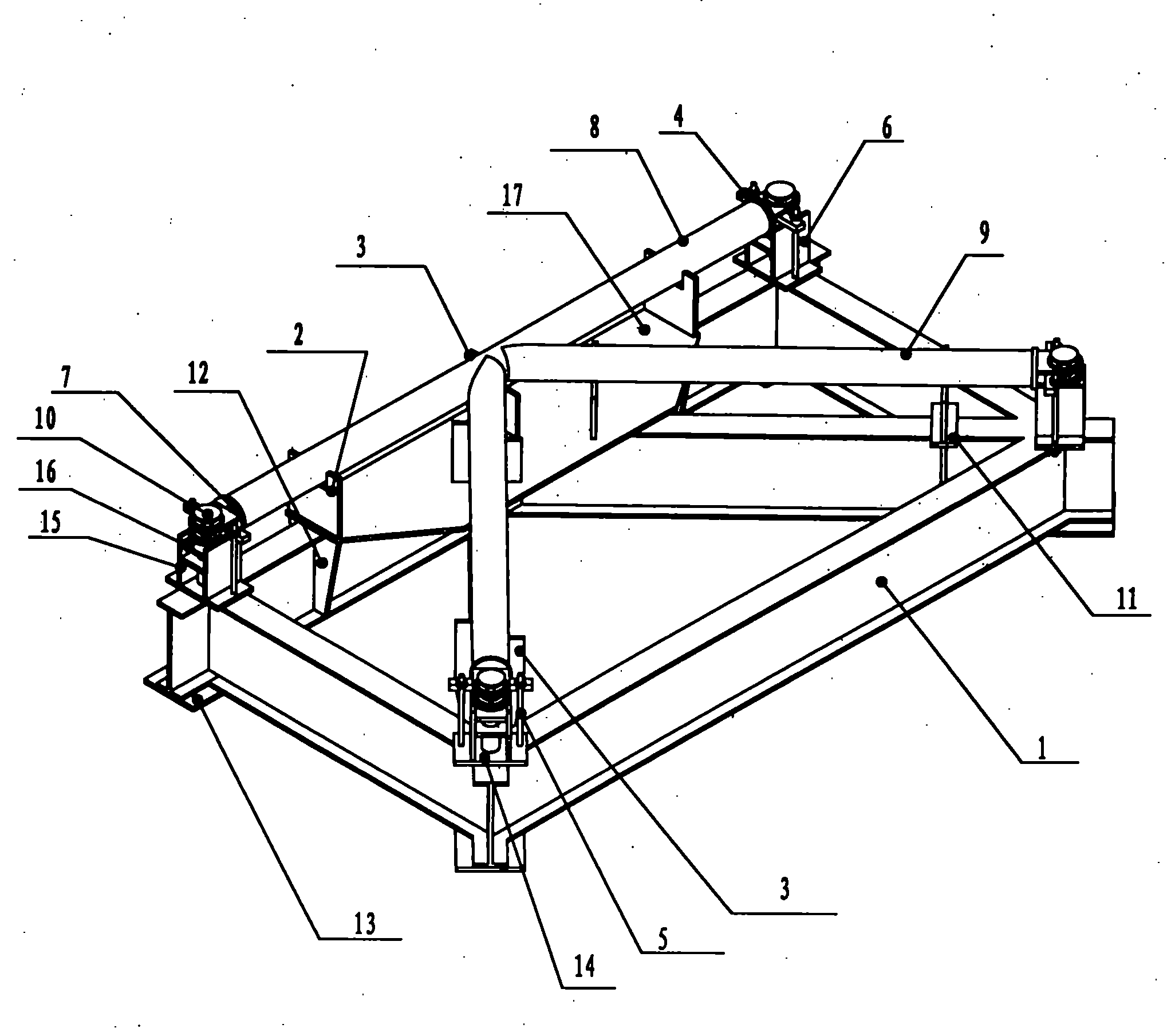

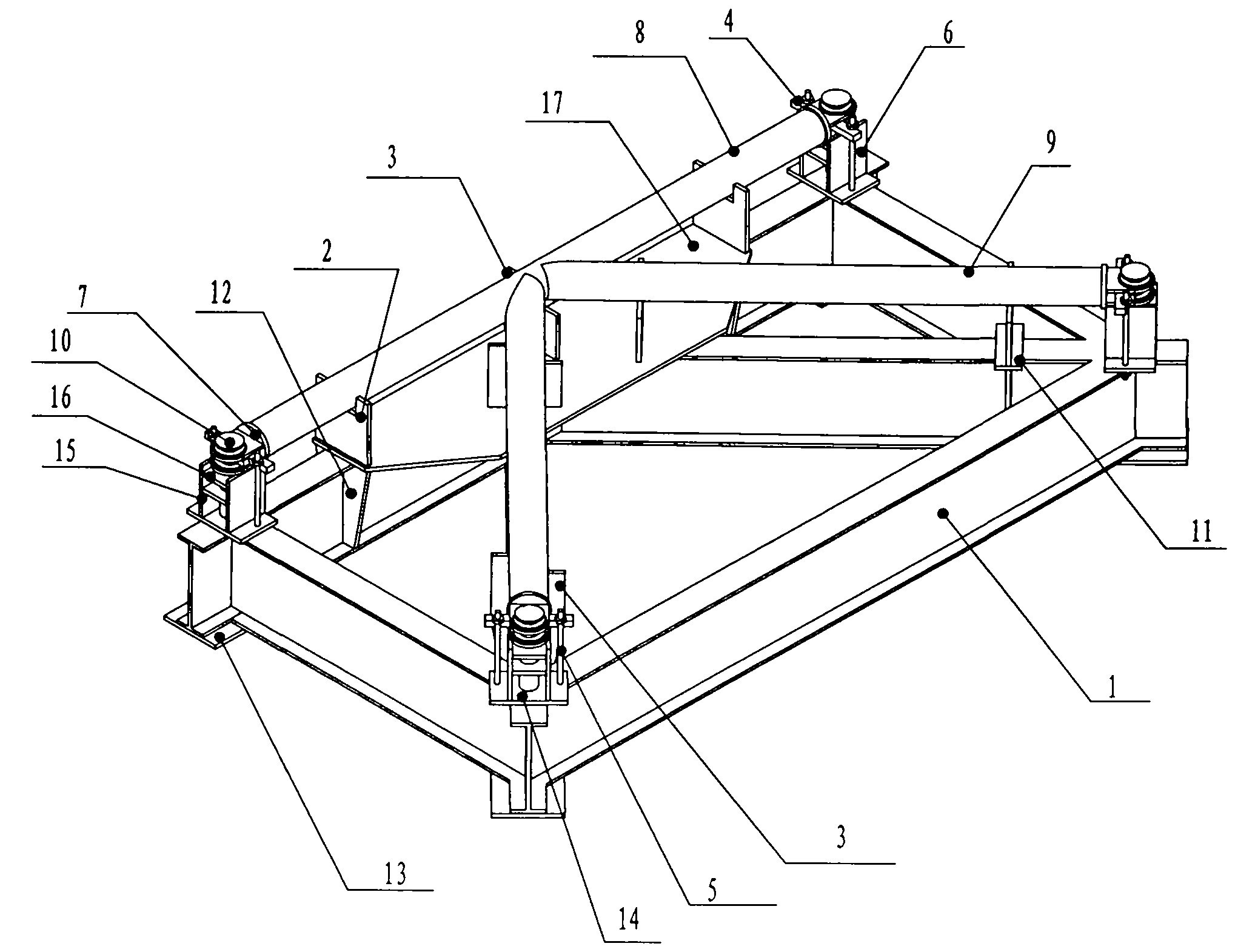

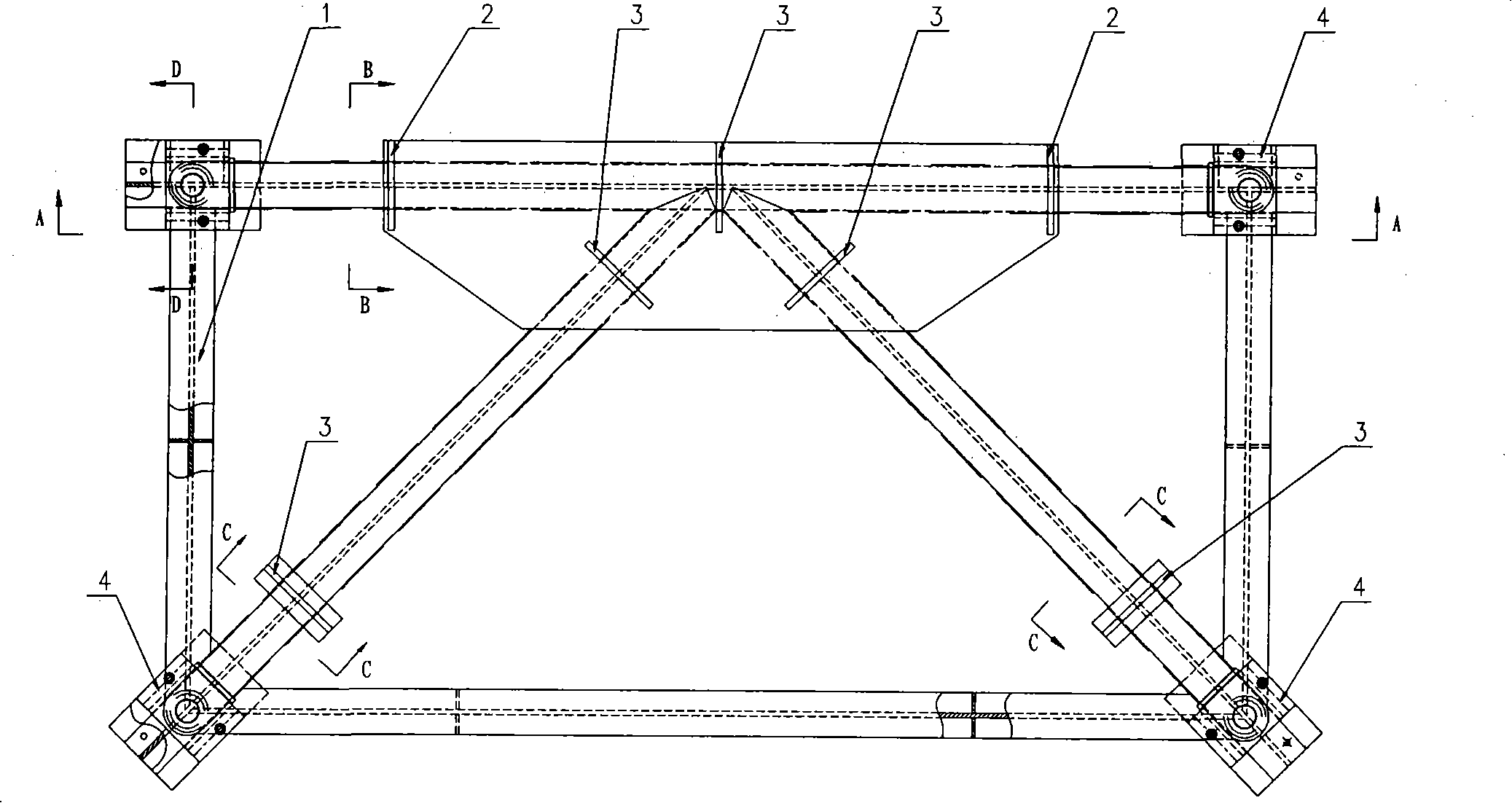

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] In Figure 1-6, the whole tooling is mainly divided into upper and lower parts: in the figure, the frame 1 (support) part is composed of "I"-shaped steel beams, and the positioning device part is composed of steel plates, pressure plates 4 and fixing bolts 5. Frame 1 is a supporting frame composed of "I"-shaped steel beams connected. The supporting frame is composed of six "I"-shaped steel beams, of which three "I"-shaped steel beams form a K-shaped shape, and the other three "I"-shaped steel beams are in turn Connect the endpoints of the K-shaped structure to form a closed body. A web 13 is respectively arranged as a support plane at four butt joint corners at the bottom of the frame and is welded firmly. Ribs 12 are provided on the inner side of the frame. The whole frame 1 is placed on the ground and does not need to be fixed.

[0024] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com