Center coiling type synthetic leather product inspection machine

A finished product inspection, synthetic leather technology, applied in the inspection of textile materials, winding strips, textiles and papermaking, etc. Ensure product quality and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

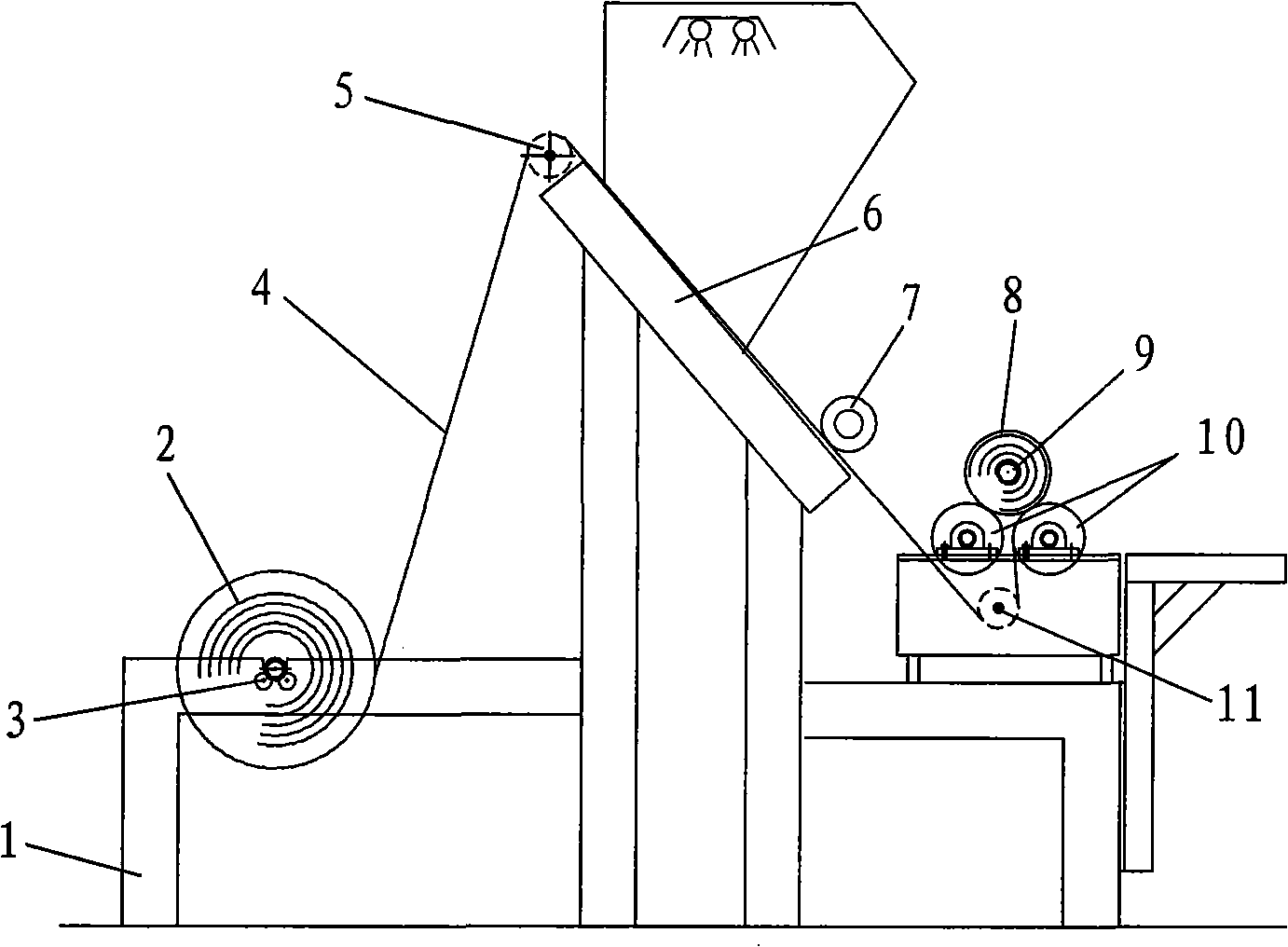

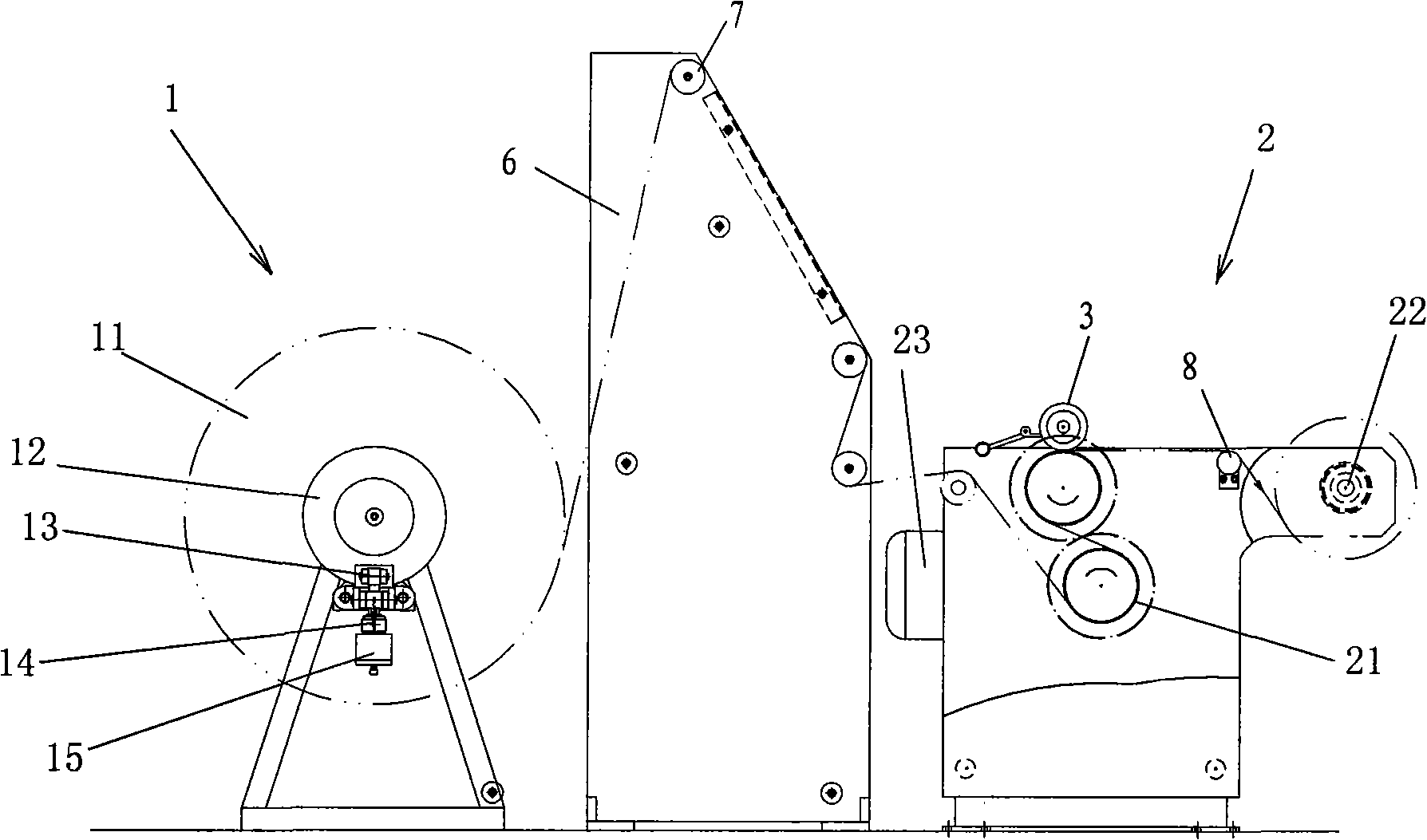

[0023] see figure 2 , image 3 , the inspected product is led out from the unwinding roller 11 in the unwinding unit 1, passes through the transition roller 7 on the inspection table after passing through the inspection table 6, and is pulled by the traction roller 21 in the rewinding unit 2 and wound on the rewinding unit 2 on the central winding rod 22; the tension of the unwinding roller 11 is adjustable, and the central winding rod 22 is driven by the traction roller 21 and has the same linear speed as the traction roller 21.

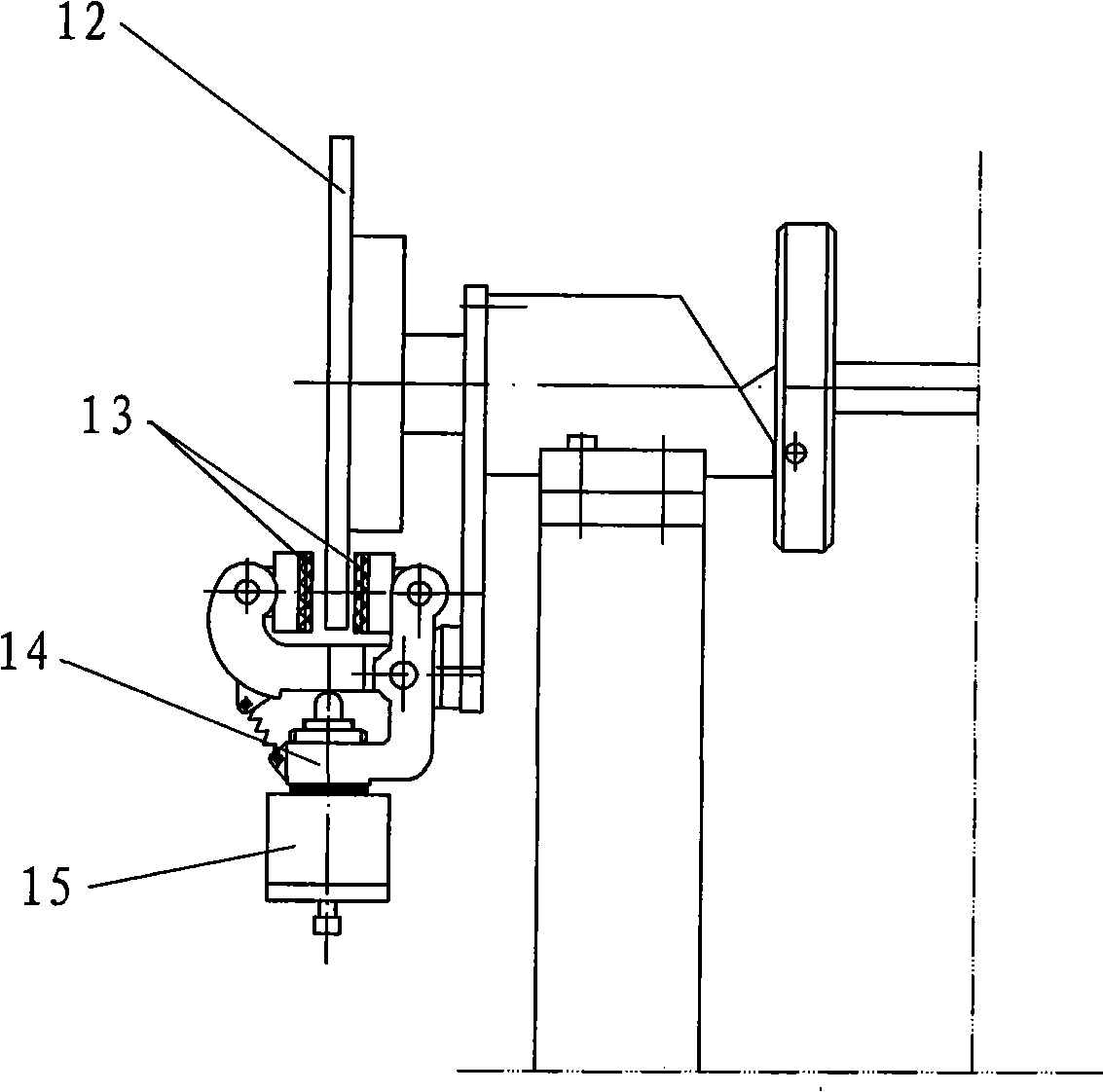

[0024] In specific implementation, as figure 2 , image 3 As shown, an unwinding tension control mechanism is set in the unwinding unit 1, and the unwinding tension control mechanism is an air-clamp friction disc. The piece 13 is fixedly arranged on the two jaws of the air clamp 14, and the clamping force between the two jaws of the air clamp 14 is pneumatically adjustable; image 3 As shown, a power cylinder 15 with controllable pressure is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap