Novel reverse flow preventing device

A backflow preventer, a new type of technology, applied in the direction of functional valve types, valve details, control valves, etc., can solve the problems that affect the system efficiency, cannot form an effective check, and the spring pressure is large, so as to achieve a small system water loss and one-way Good non-return effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] This embodiment is used to explain the claims of the present invention, and the protection scope of the present invention is not limited to the structures described below.

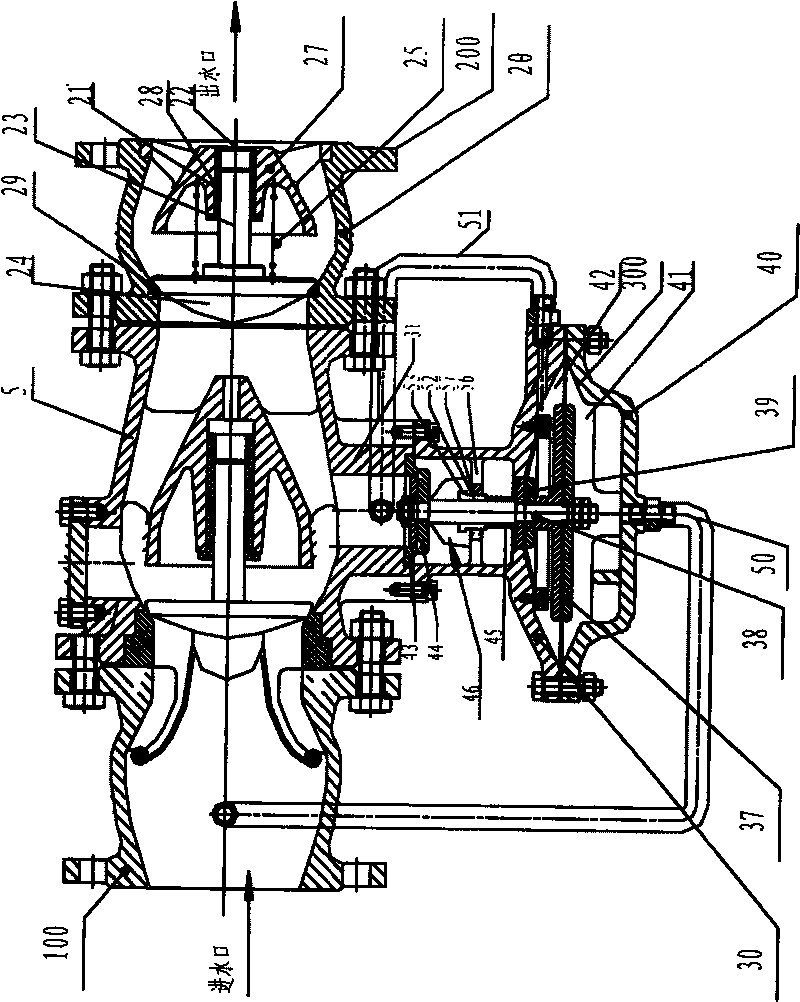

[0013] Such as figure 1 As shown, the first check valve 100 and the second check valve 200 are connected in series. Wherein, the middle valve body 5 is not only the rear valve body of the first check valve 100 but also the front valve body of the second check valve 200 . A drain valve 300 is connected to the valve body of the water outlet section of the first check valve 100 .

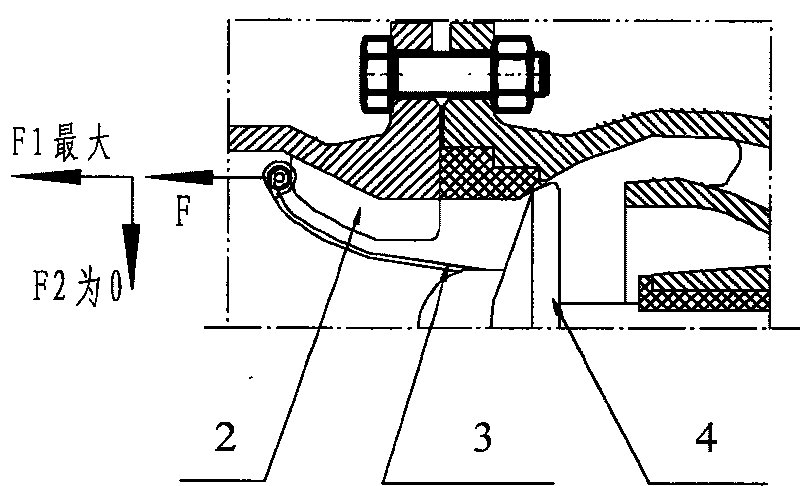

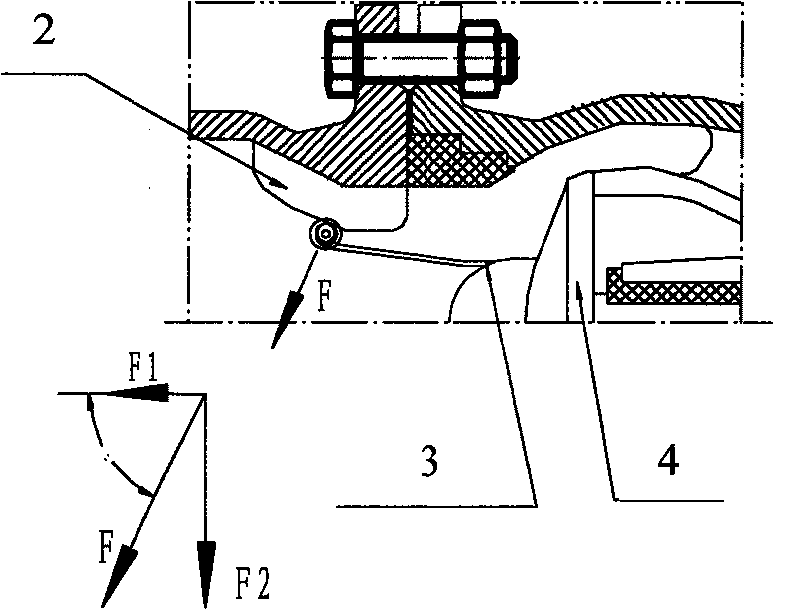

[0014] The structure of the first check valve 100 is as follows: Figure 4 As shown: the valve body of the first check valve 100 is composed of the front valve body 1 and the middle valve body 5 connected by bolts 6 . A valve seat 19 is arranged inside the middle valve body 5 . The disc guide body 7 in the middle valve body 5 is provided with a guide hole 8 on the disc guide body 7 , and the diversion hole 9 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com