Liquid level detector

A technology of liquid level detection and relative position, applied in the direction of buoy liquid level indicator, etc., can solve the problems of explosion, small energy consumption, hidden safety hazards, etc., and achieve the effect of wide application range, energy saving and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

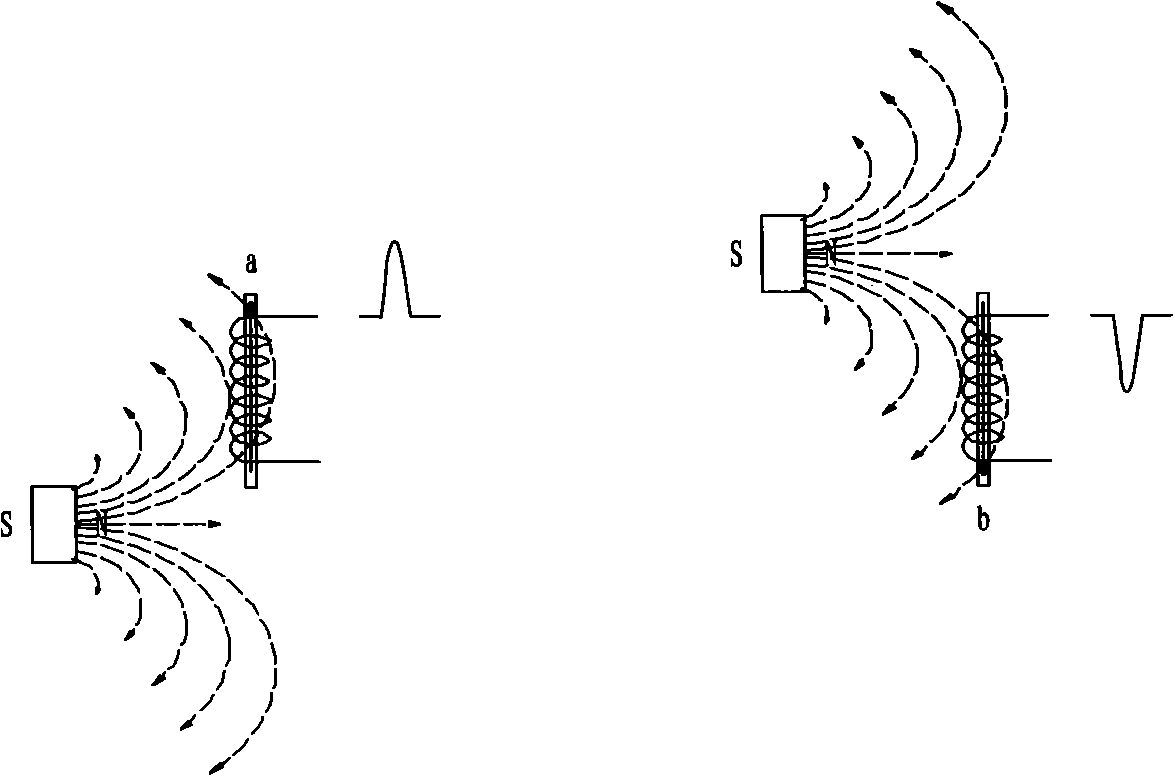

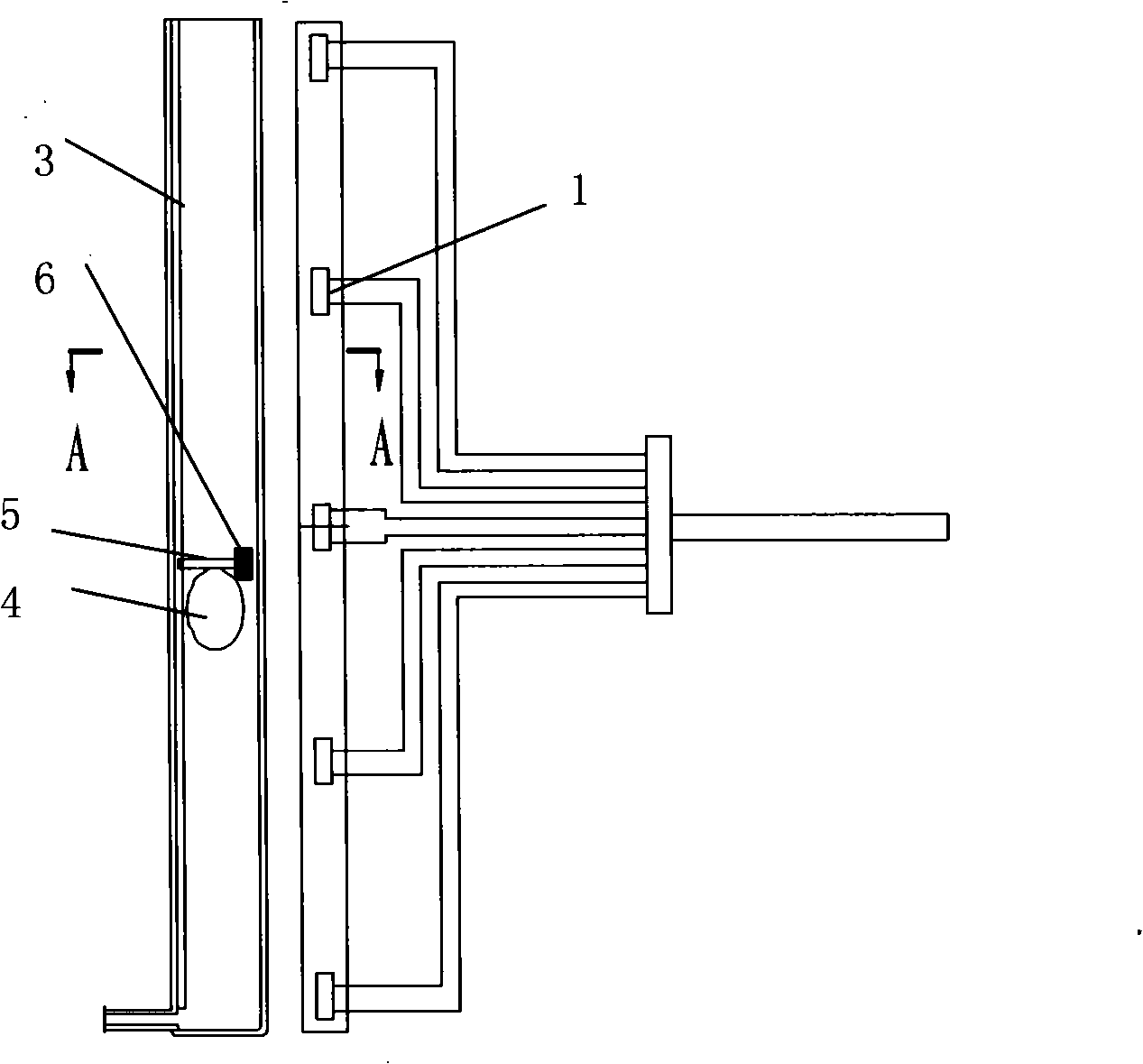

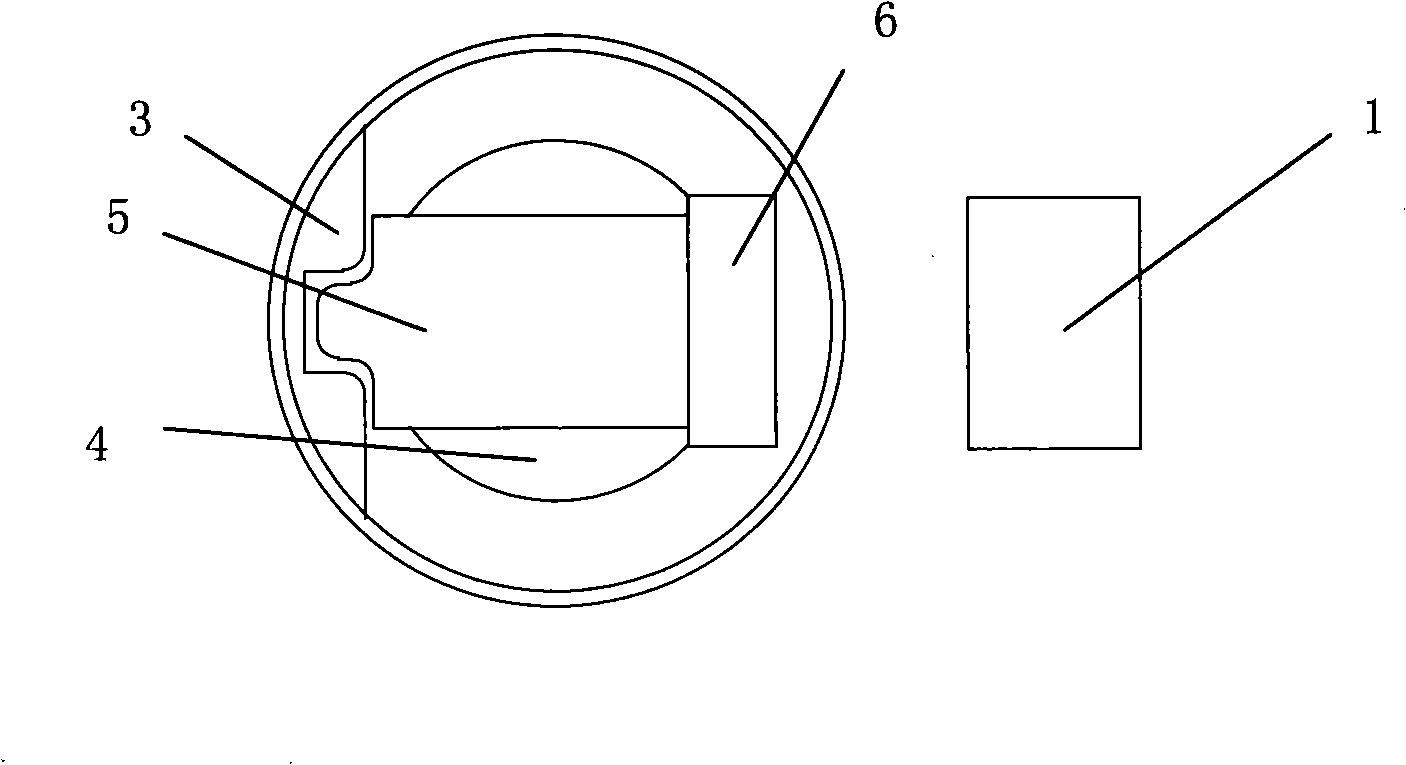

[0019] Such as figure 1 As shown, the dotted line indicates the magnetic field distribution of the magnet 6, and the arrow indicates the direction of the magnetic field. When the magnet 6 is close to the lower end of the magnetic sensor 1, the magnetic induction intensity component parallel to the sensitive wire 2 reaches the set value B, so that the magnetization direction of the sensitive wire 2 points to a, and the coil induces a positive electric pulse; when the magnet 6 rises to At the upper end of the magnetic sensor 1, the magnetic field at the sensitive wire 2 is reversed, the magnetic induction intensity component parallel to the sensitive wire 2 reaches the set value -B, the magnetization direction of the sensitive wire 2 is instantly reversed to point b, and the coil induces a reverse electric current pulse. The magnetic sensor 1 made of magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com