Bearing assembly

A technology for bearing devices and rolling bearings, applied to bearings, bearing elements, shafts and bearings, etc., can solve the problems of oil aging and service life impact, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

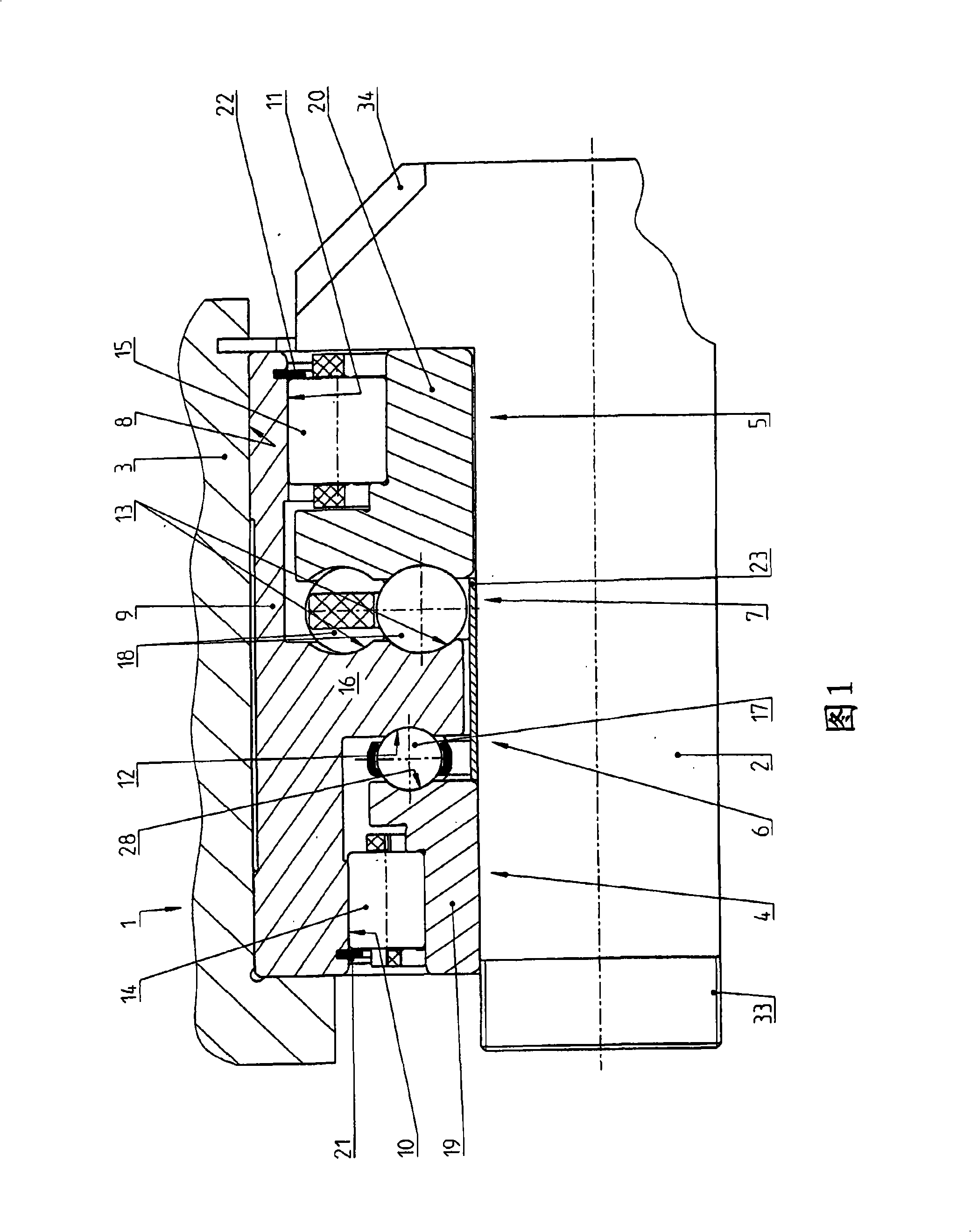

[0026] FIG. 1 shows a bearing arrangement 1 which radially and axially supports a shaft part 2 in the form of a bevel pinion shaft with a bevel pinion 34 relative to a housing 3 . The bearing arrangement 1 is located in a bore 8 in the housing 3 . The bearing arrangement 1 has two radial rolling bearings 4 and 5 designed as cylindrical roller bearings and two axial rolling bearings 6 and 7 designed as ball bearings. Both cylindrical roller bearings 4 , 5 and axial ball bearings 6 , 7 are each arranged at an axial distance from one another.

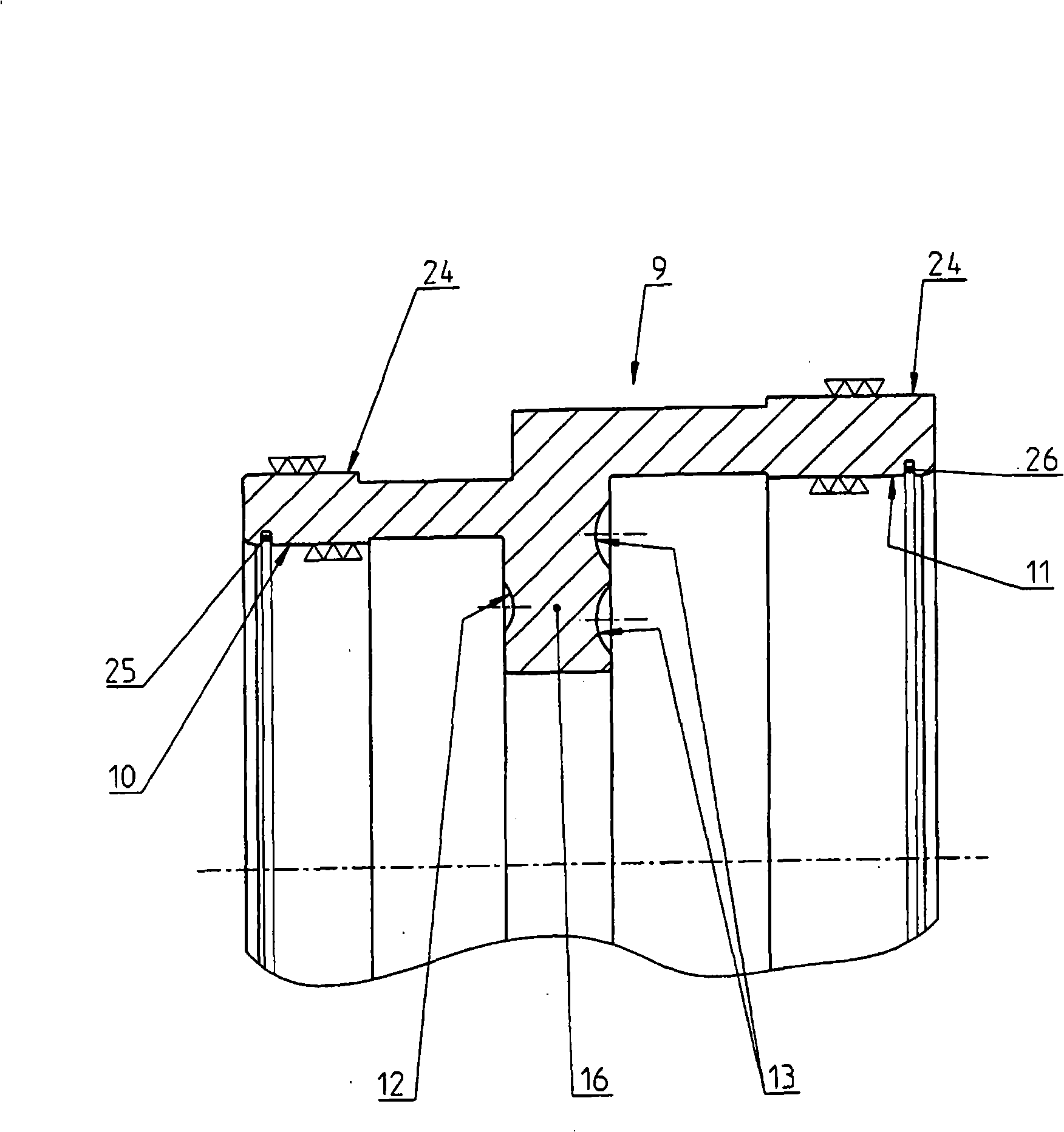

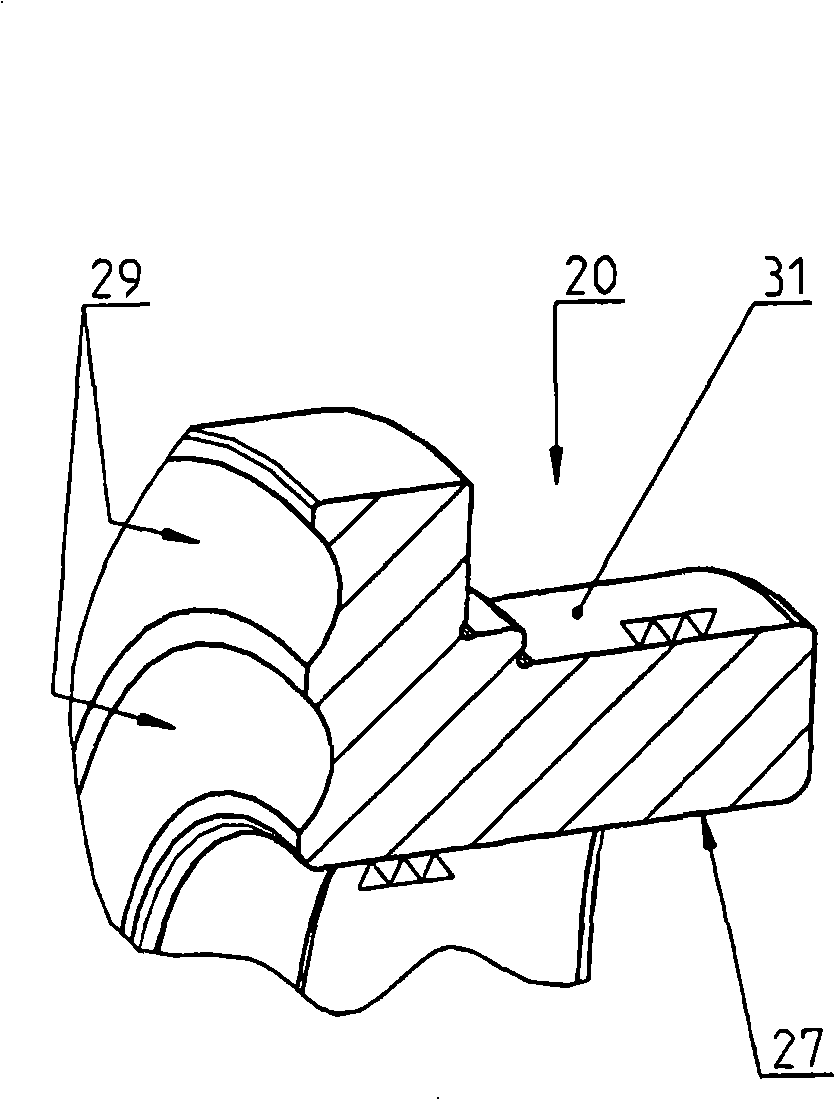

[0027] The bearing outer ring 9 is formed in one piece and has all the raceways 10 , 11 , 12 and 13 for the two cylindrical roller bearings and for the two axial ball bearings. The two cylindrical raceways 10 and 11 for the two cylindrical roller bearings are located in the region of the two axial ends of the bearing outer ring 9 . In the central region, the ring segment 16 extends radially inwards. Ball raceways 12 or 13 are formed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com