Clutch metal strap type soft starting device

A metal belt type and clutch technology, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., to achieve high transmission efficiency, stepless speed regulation, and smooth starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

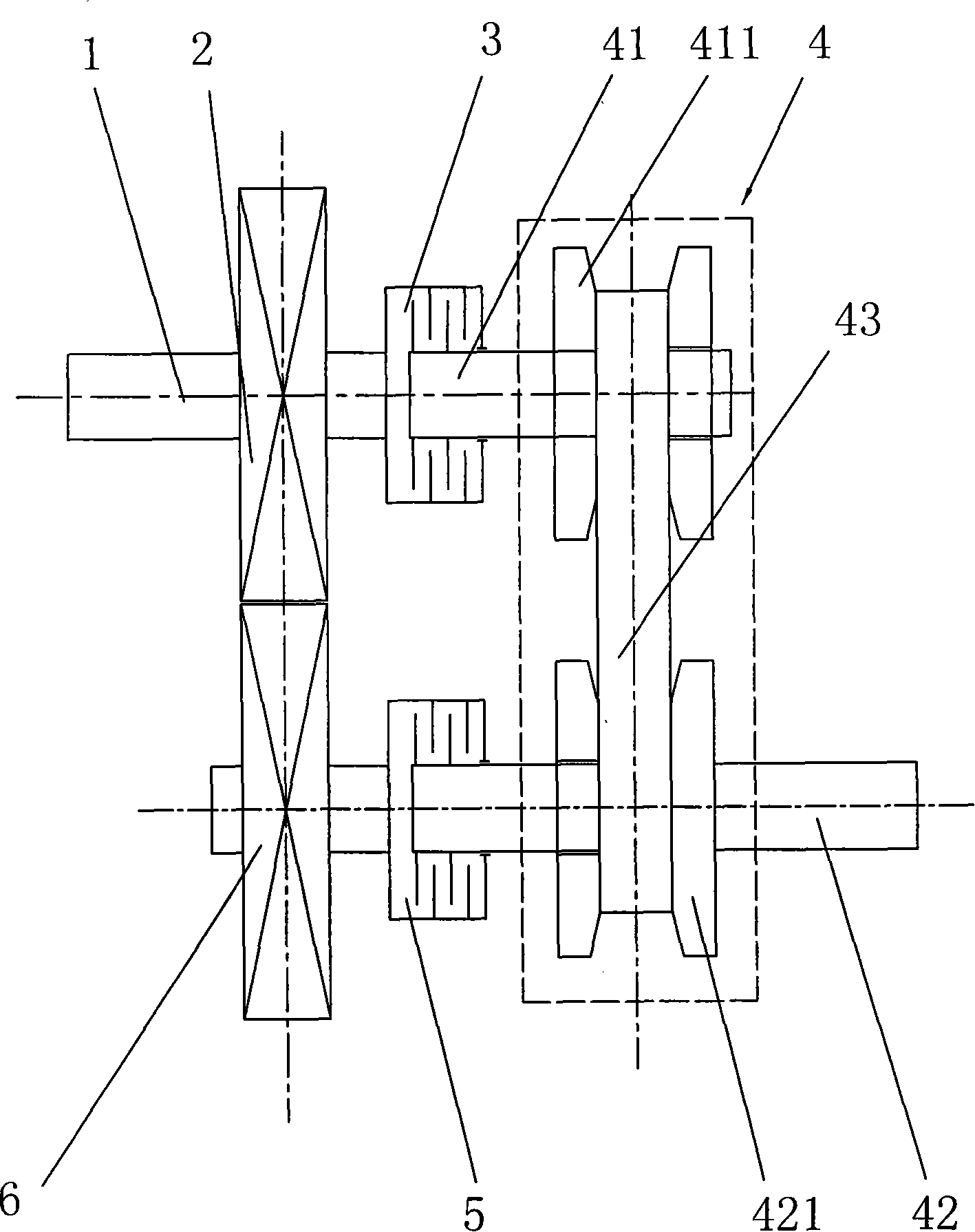

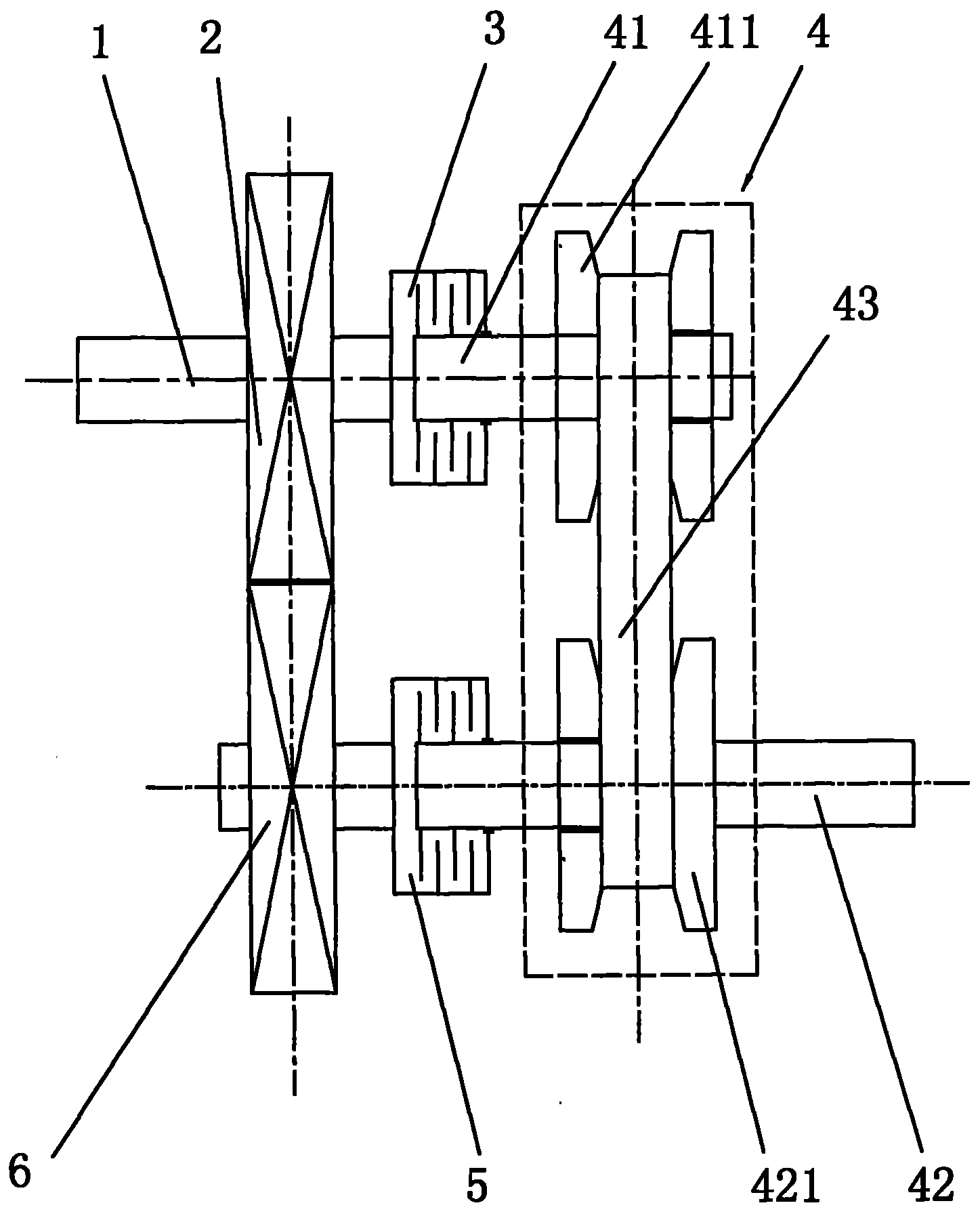

[0016] as attached figure 1 As shown, the clutch metal belt type soft starter of the present invention includes a power input shaft 1, on which a driving gear 2 is arranged, and the end of the power input shaft 1 passes through a fluid viscous clutch 3 and a metal belt assembly 4 The driving shaft 41 is connected with the driving shaft 41, the driving shaft 41 is sleeved with a driving pulley 411, the driven shaft 42 of the metal belt assembly 4 is a power output shaft, the driven shaft 42 is sleeved with a driven pulley 421, and the driving pulley 411 and the driven pulley 421 are connected by a metal belt 43, the end of the driven shaft 42 is connected with the axle of the driven gear 6 through the fluid viscous clutch 5, the driving gear 2 is meshed with the driven gear 6, and the transmission ratio is 1:1.

[0017] When the motor starts, the clutch 3 and the clutch 5 are in the clutch state, and the power input shaft 1 only drives the driving gear 2 and the driven gear 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com