Digital pressure regulating valve

A pressure regulating valve, digital technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, servo motor components, etc., can solve the problems of high labor intensity of test personnel, low degree of automatic operation, complex hydraulic system, etc. , to achieve the effect of preventing insufficient starting power, high degree of automatic operation, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

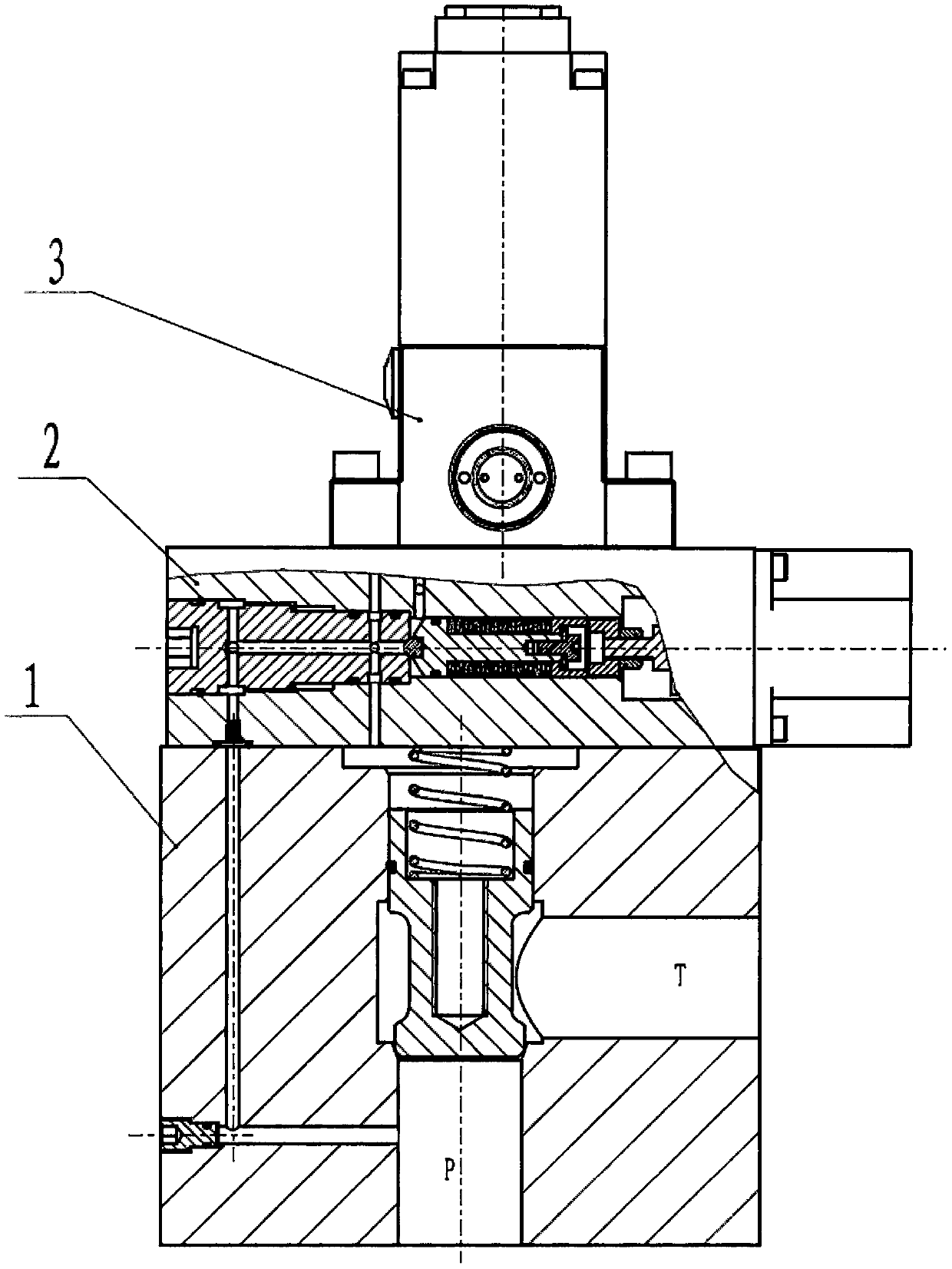

[0030] figure 1 As shown, the digital pressure regulating valve mainly includes a main valve part 1, a pilot valve part 2, and an electromagnetic pilot valve 3.

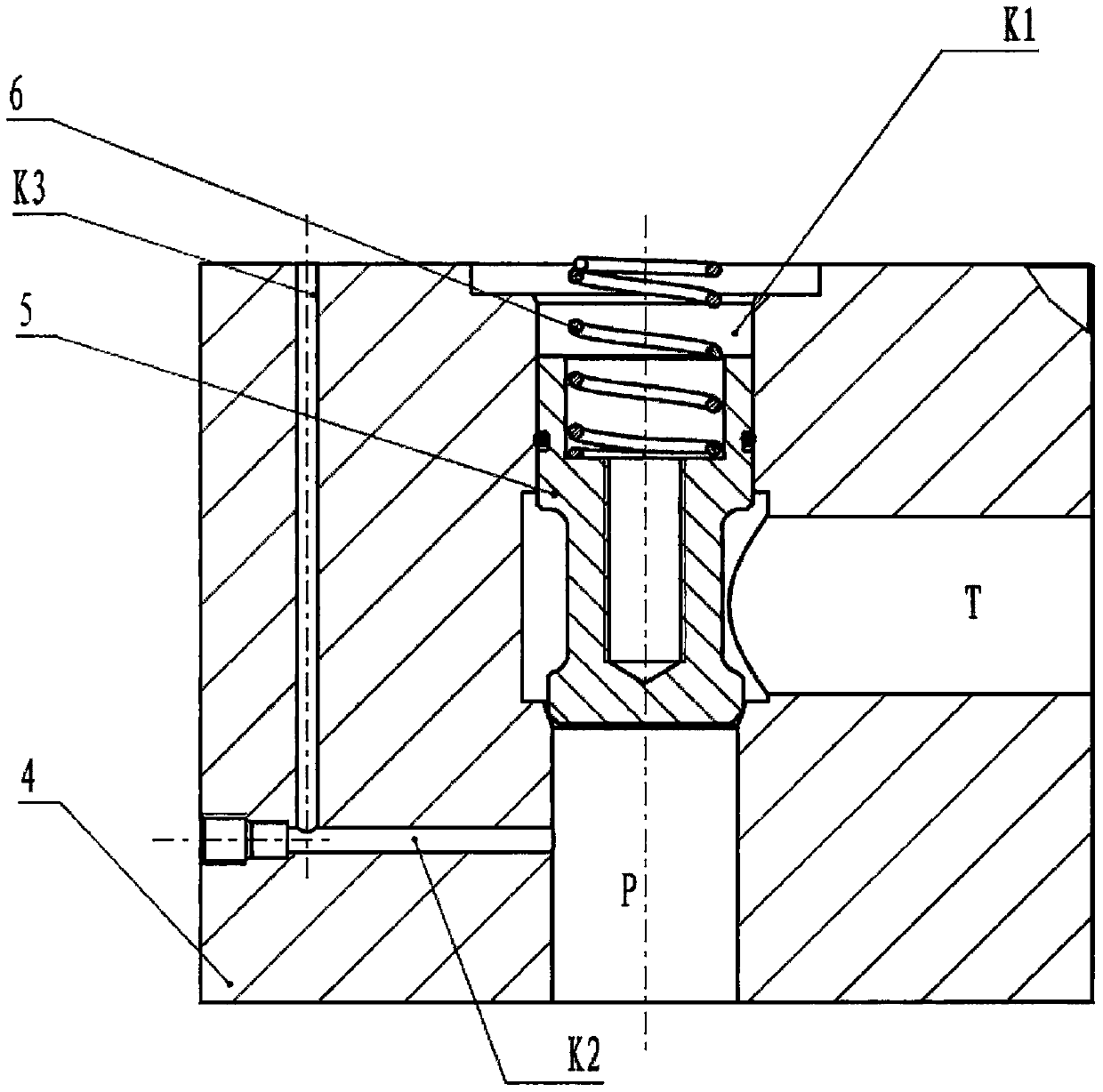

[0031] like figure 2 As shown, the main valve part includes the main valve body 4, the main valve body 4 is opened with the main valve core chamber K1, the liquid inlet P, and the liquid outlet T, the main valve core chamber K1 is equipped with the main valve core 5, the main valve core 5. There are threaded holes in the inner processing, which is convenient for disassembly and assembly. The main valve core is provided with a return spring 6, which is in a compressed state. The lower end compresses the pilot valve core 5 to reliably seal with the sealing cone surface in the main valve body 4, and the upper end connects with the pilot valve body 7. At the same time, the main valve body 4 is provided with a main valve fluid hole A K2 and a main valve fluid hole B K3.

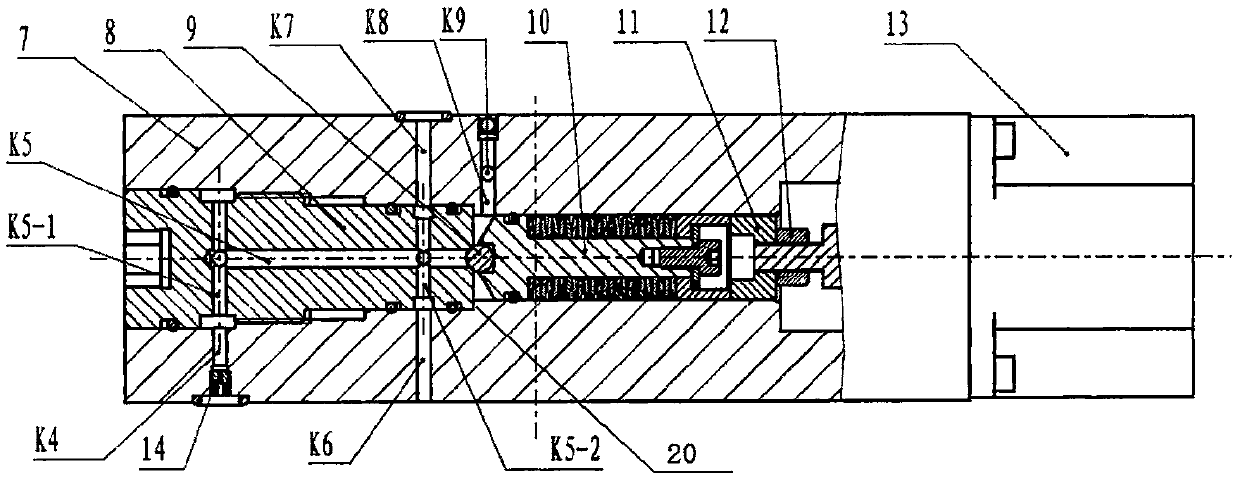

[0032] like image 3 As shown, the pilot valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com