Method of selecting a transmission shift schedule

A technology of shifting regularity and transmission, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description is merely exemplary in nature and is not intended to limit the invention and its uses.

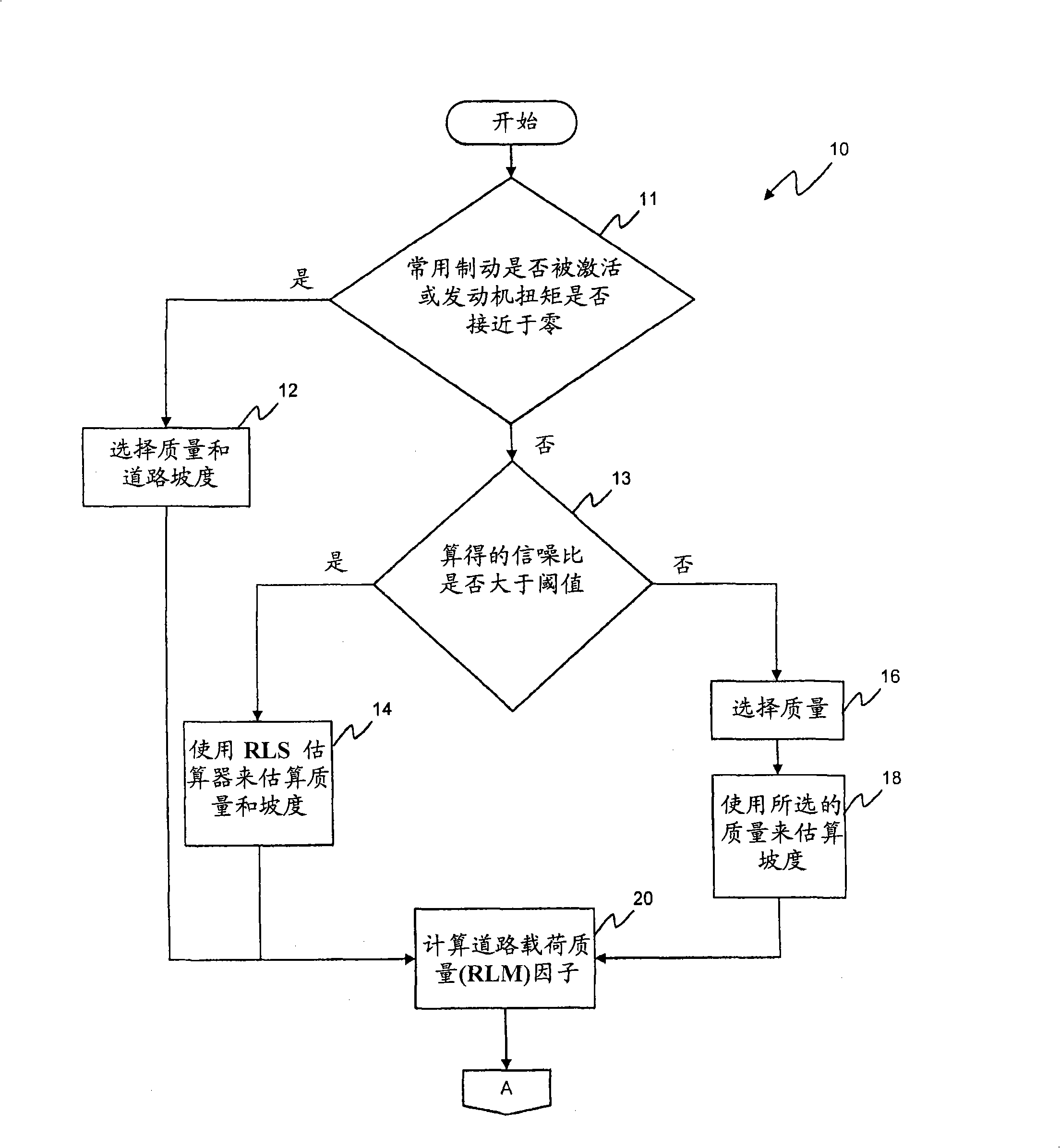

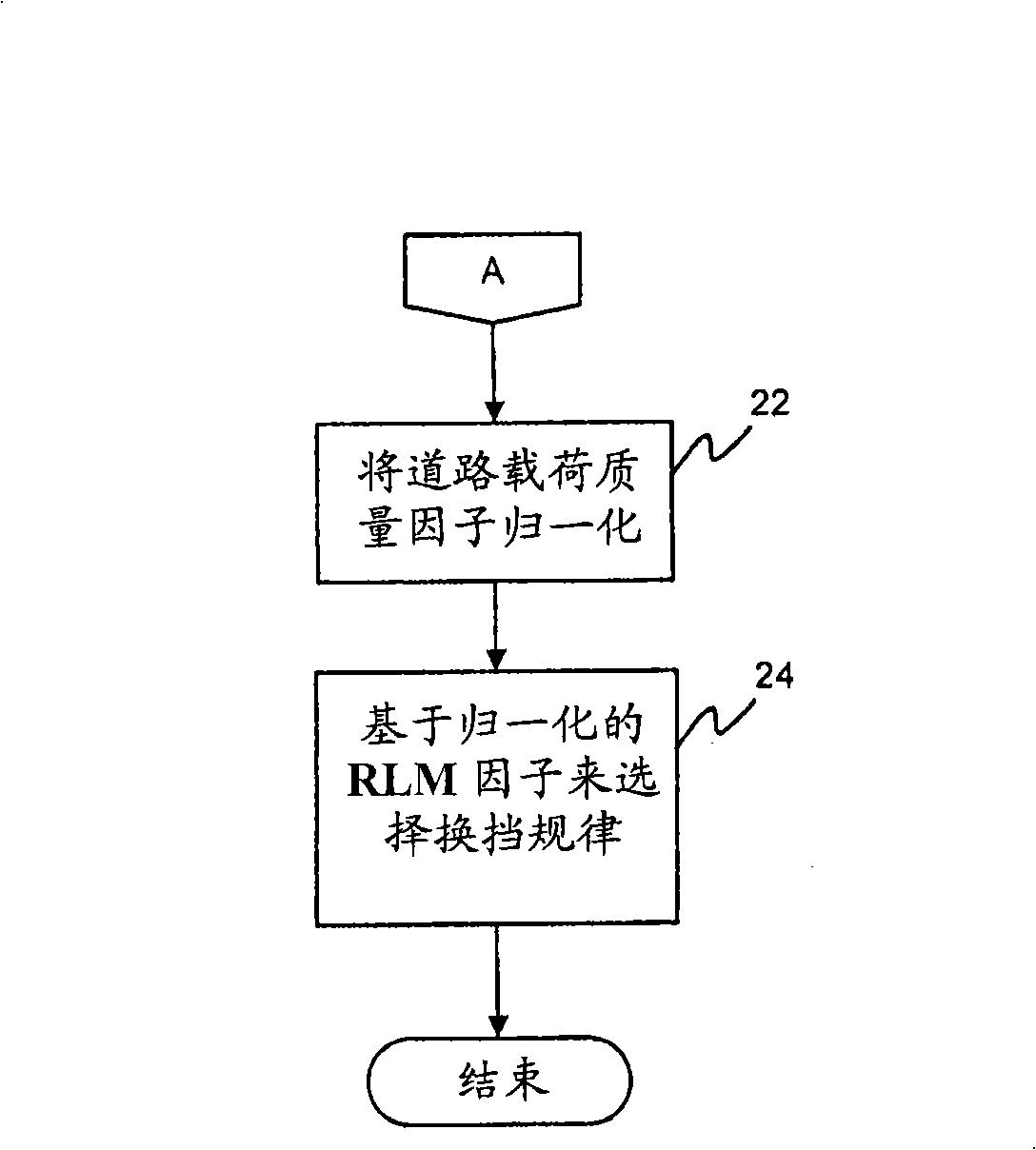

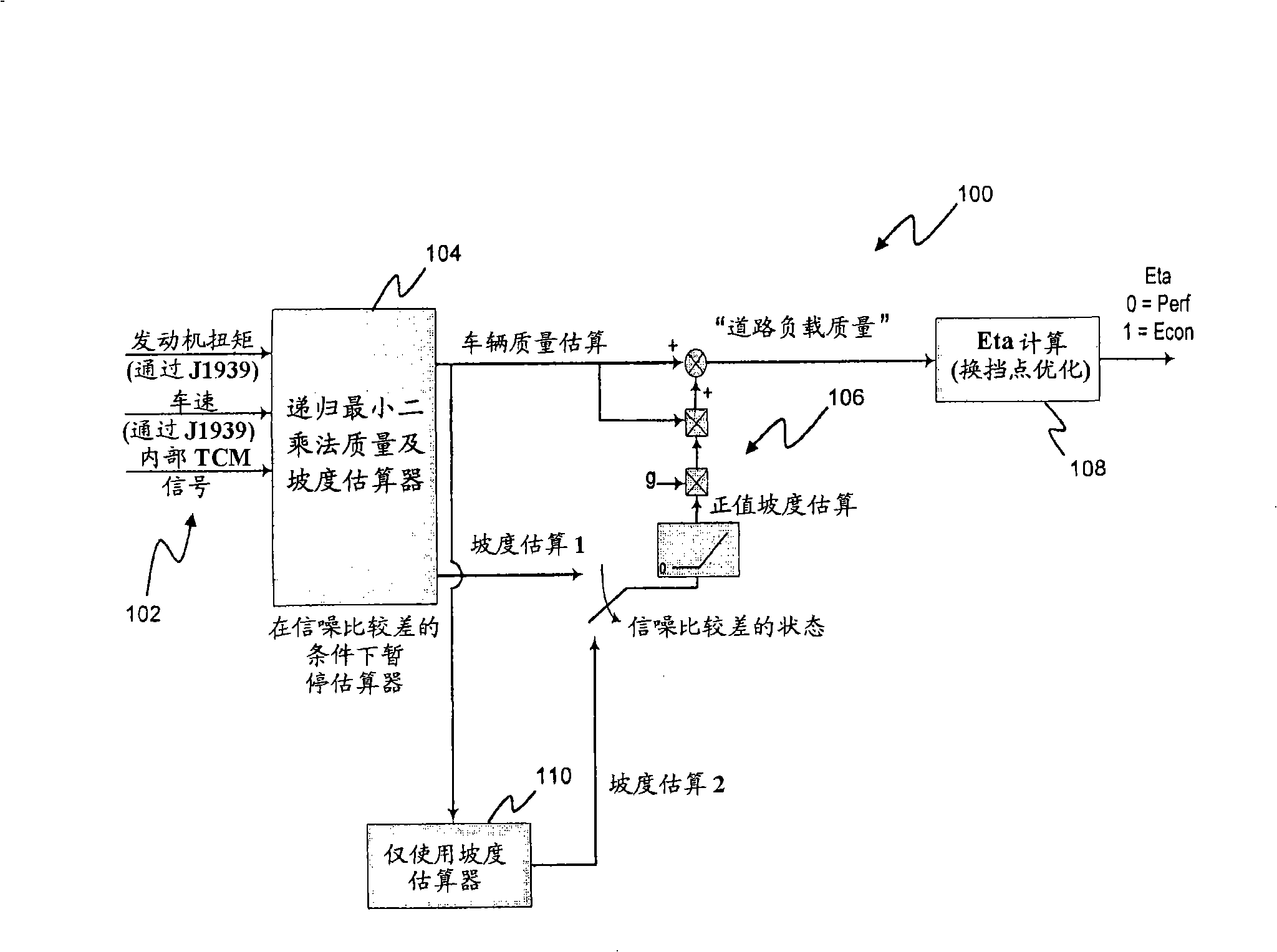

[0028] refer to Figure 1A and 1B , numeral 10 generally shows a method for selecting a shift schedule for an automatic transmission in an automobile. An automobile (not shown) typically includes a powertrain with an engine and an automatic transmission. As the car travels, the slope of the road may vary between a flat slope and a steep slope, depending on the given route. In addition, the mass of the car may also change due to changes in the number of passengers, luggage, storage items, the presence of a trailer or other trailers, etc. Method 10 estimates the road gradient and vehicle mass at any given moment in order to select a shift schedule that suits the needs of the driver of the vehicle. Therefore, the method 10 runs continuously in real time.

[0029] Method 10 begins at step 11 where the controller determines whether a service brake is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com