Method for dynamically measuring guide rail linearity

A technology of dynamic measurement and straightness, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of inability to dynamically and continuously measure the straightness of guide rails, large visual errors, visual fatigue, etc., and achieve dynamic continuous measurement and data processing Intuitive and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

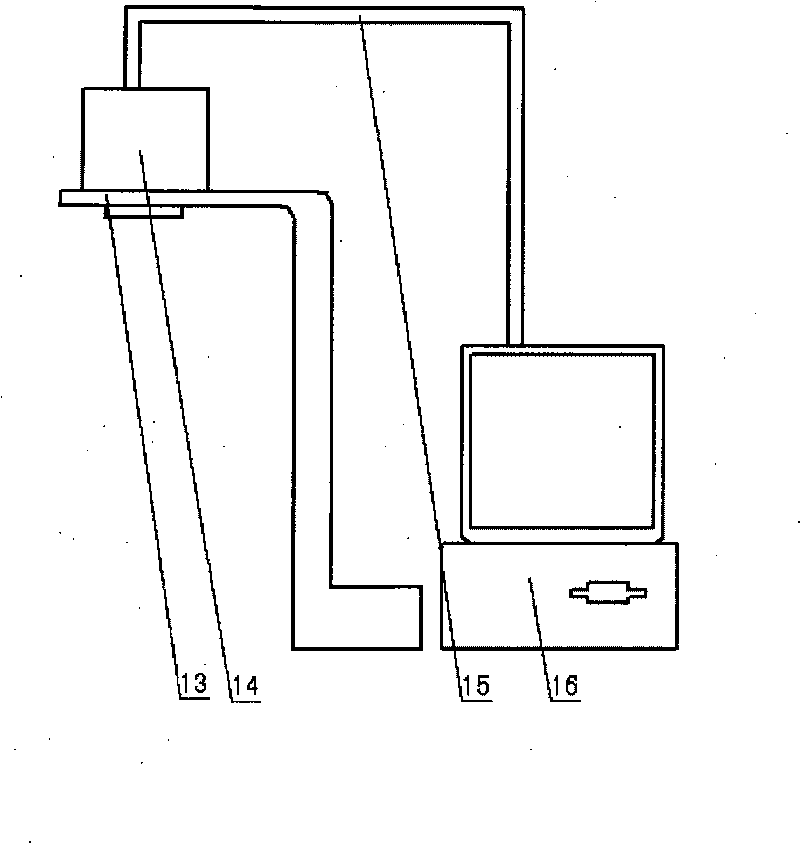

[0017] The instrument and equipment that the inventive method adopts presses Figure 4 The position shown is placed and docked on the optical measurement platform 1, and each step of the method is executed according to the five steps set in the technical plan, wherein the optical measurement platform 1 used in the first step adopts an isolated and stable platform with a foundation, and the platform’s The working surface is a 1000cm×800cm rectangular platform.

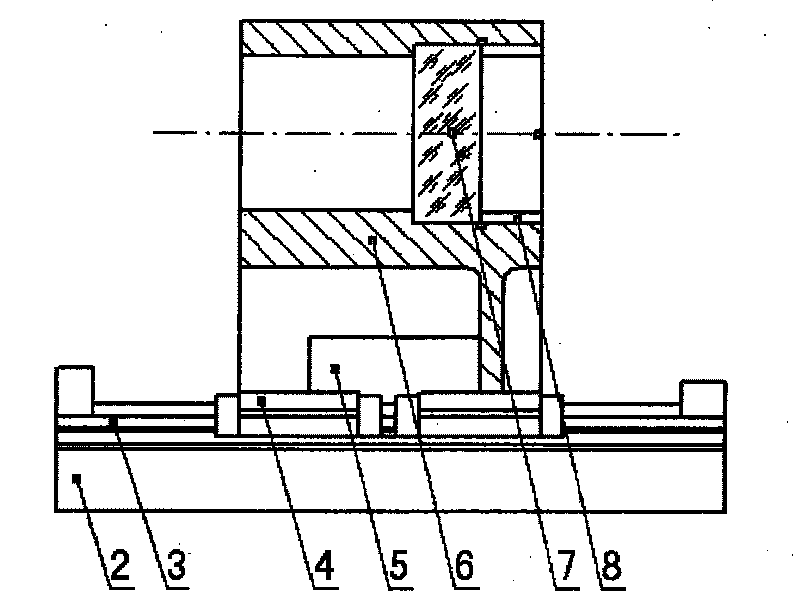

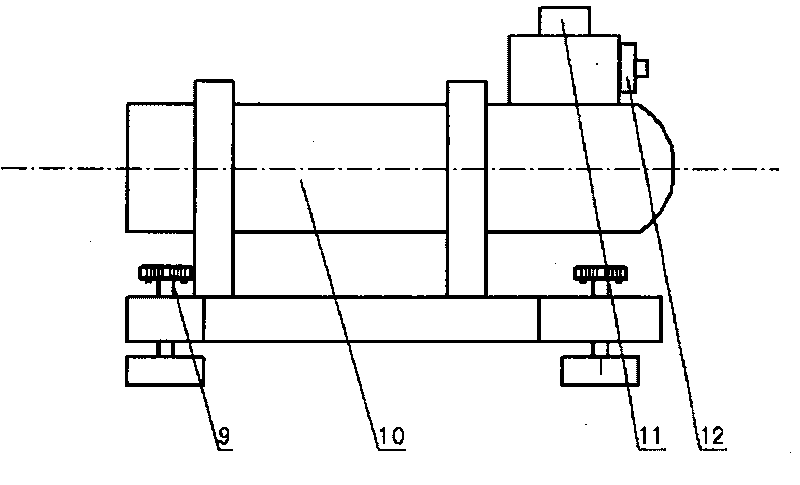

[0018] In the second step, the integrated part composed of the base 2 and the guide rail 3 is placed on the left half of the optical measurement platform 1, the slider 4 in the component to be tested is installed on the guide rail 3, and the screw rod of the linear motor assembly 5 passes through two The end seat is fixed on the base 2, the linear motor is fixed on the mirror frame, and the mirror frame is fixed on the slider. The linear motor assembly 5 drives the mirror frame and the slider 4 to move linearly along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com