Lubrication type angular contact articulated bearing

A kind of joint bearing and angular contact technology, applied in the direction of sliding contact bearings, bearing components, shafts and bearings, etc., can solve the problem of low oil storage, and achieve the effect of improving lubrication conditions, reducing wear and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

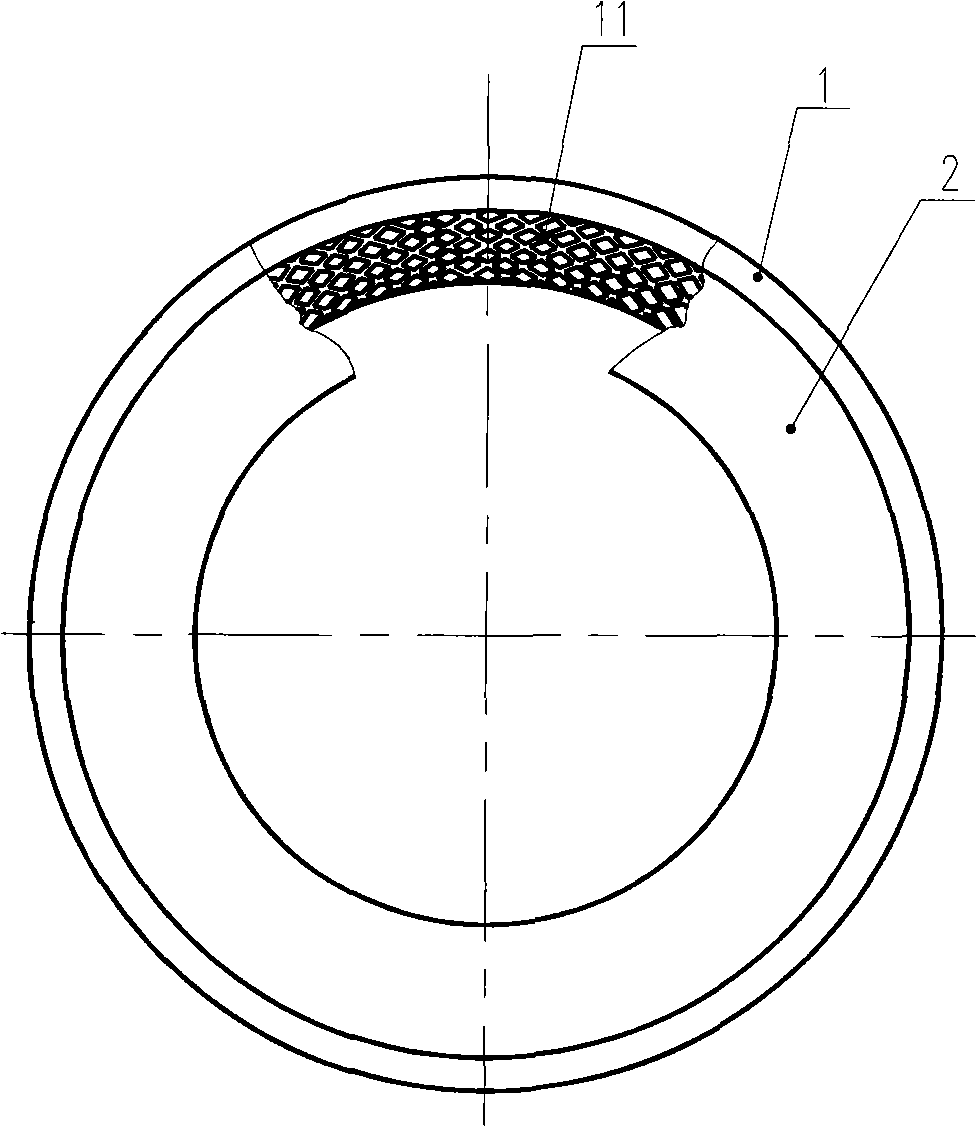

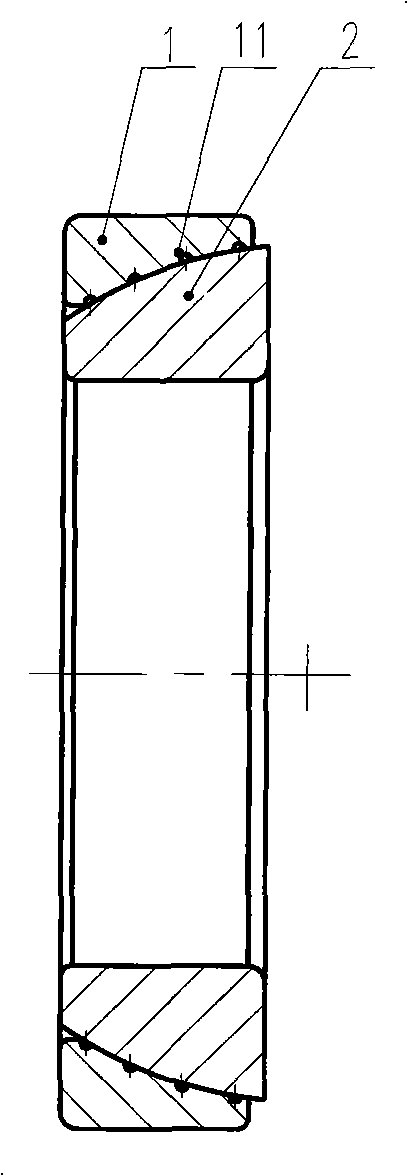

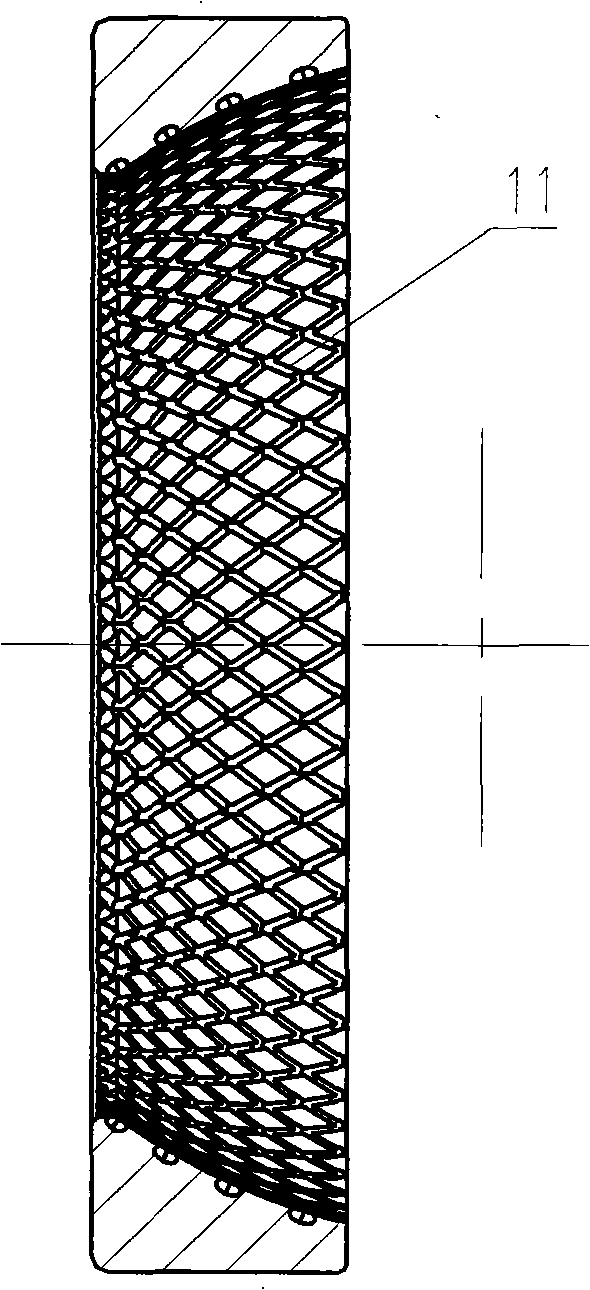

[0011] Embodiment 1: as figure 1 , figure 2 As shown, a lubricated angular contact joint bearing of the present invention is composed of an outer ring 1 and an inner ring 2, the contact surface of the inner and outer rings is the working surface, the working surface of the inner ring is an outer spherical surface, and the working surface of the outer ring is an inner spherical surface. like figure 1 , image 3 As shown, the inner spherical surface of the outer ring is processed with a mesh lubricating oil groove 11. The front and back are evenly distributed, the number of front and back is the same, and the front and back cross at 60°. The cross-sectional shape of the mesh lubricating oil groove 11 is an arc shape. The specific processing method is as follows: according to the ordinary joint bearing processing method, the inner spherical surface of the outer ring of the bearing is turned, and then the forming milling cutter is used on the processing center, and the indexin...

Embodiment 2

[0012] Embodiment 2: as figure 1 , figure 2 As shown, a lubricated angular contact joint bearing of the present invention is composed of an outer ring 1 and an inner ring 2, the contact surface of the inner and outer rings is the working surface, the working surface of the inner ring is an outer spherical surface, and the working surface of the outer ring is an inner spherical surface. like figure 1 , image 3 As shown, the inner spherical surface of the outer ring is processed with a mesh lubricating oil groove 11, the front and back of which are evenly distributed, the number of front and back is the same, and the front and back intersect at 50°. The cross-sectional shape of the mesh lubricating oil groove 11 is an arc shape. The specific processing method is as follows: according to the ordinary joint bearing processing method, the inner spherical surface of the outer ring of the bearing is turned, and then the forming milling cutter is used on the processing center, an...

Embodiment 3

[0013] Embodiment 3: as figure 1 , figure 2 As shown, a lubricated angular contact joint bearing of the present invention is composed of an outer ring 1 and an inner ring 2, the contact surface of the inner and outer rings is the working surface, the working surface of the inner ring is an outer spherical surface, and the working surface of the outer ring is an inner spherical surface. like figure 1 , image 3 As shown, the inner spherical surface of the outer ring is processed with a mesh lubricating oil groove 11, the front and back of which are evenly distributed, the number of front and back is the same, and the front and back intersect at 70°. The cross-sectional shape of the mesh lubricating oil groove 11 is a triangle. The bottom of the top corner is arc-shaped. The specific processing method is as follows: according to the ordinary joint bearing processing method, the inner spherical surface of the outer ring of the bearing is turned, and then the forming milling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com