Methods for the electrolytic production of erythrose or erythritol

A technology of erythritol and erythritol, which is applied in electrolytic organic production, electrolytic components, electrolytic process, etc., can solve problems such as foaming, expensive erythritol, and the amount of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

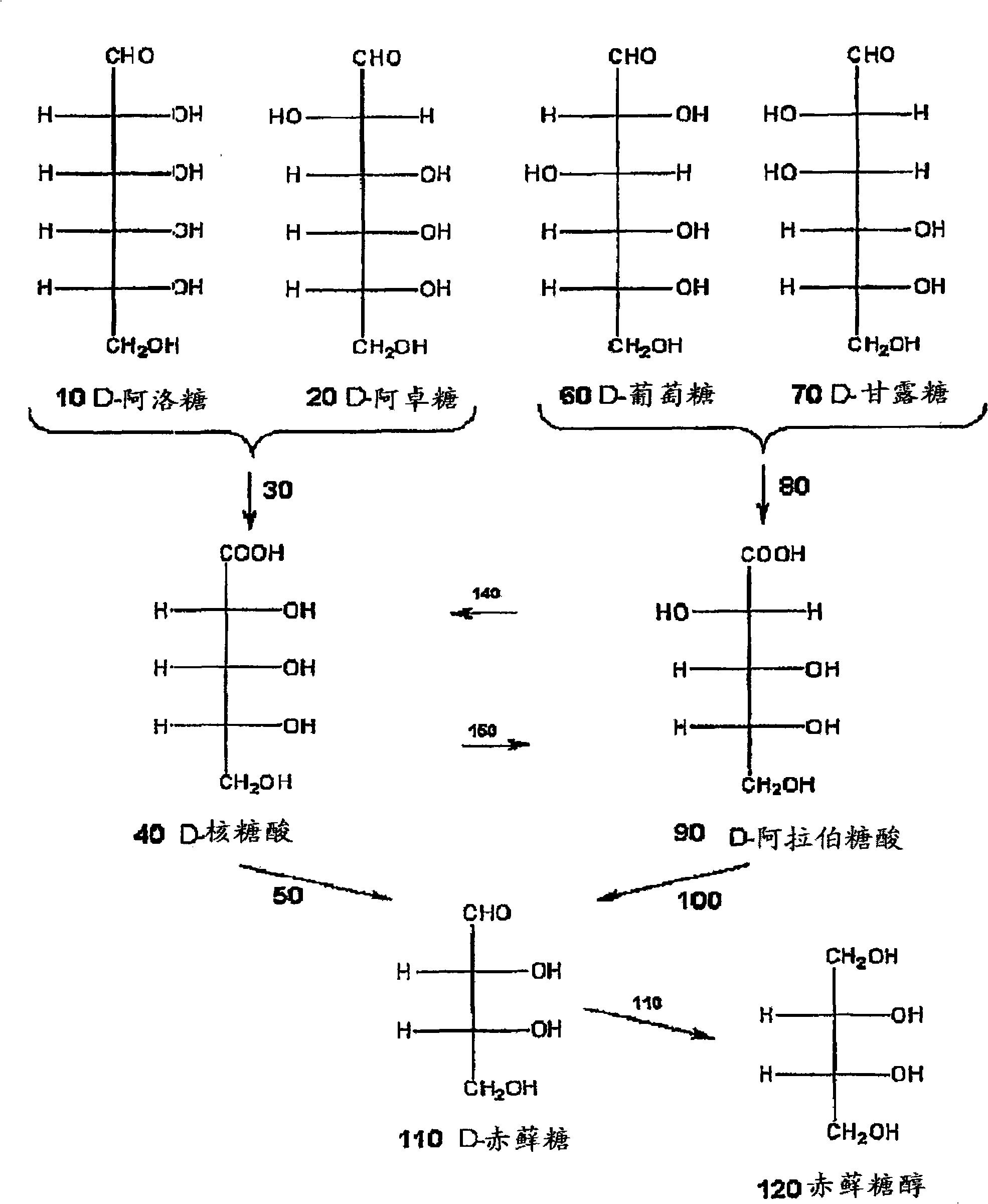

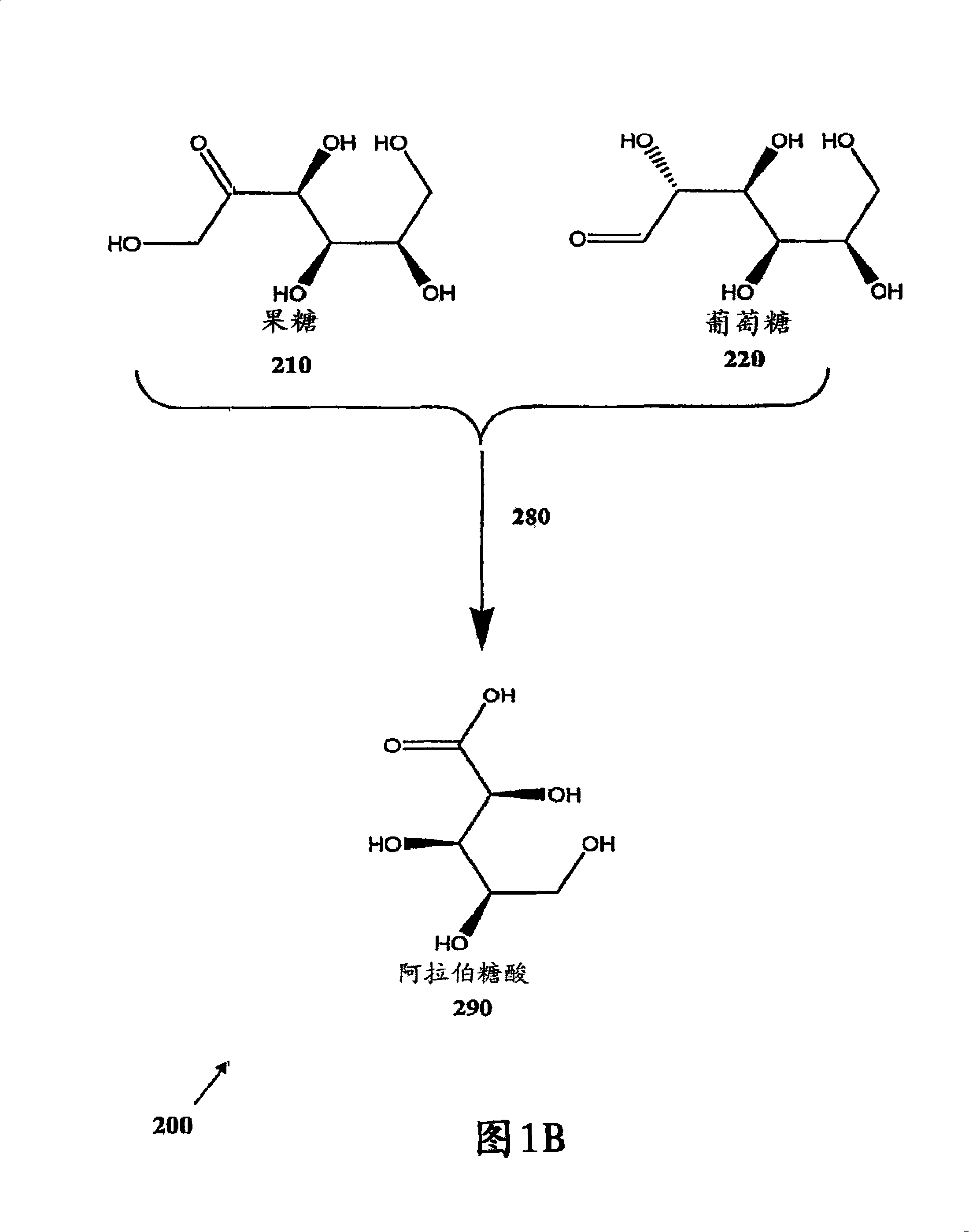

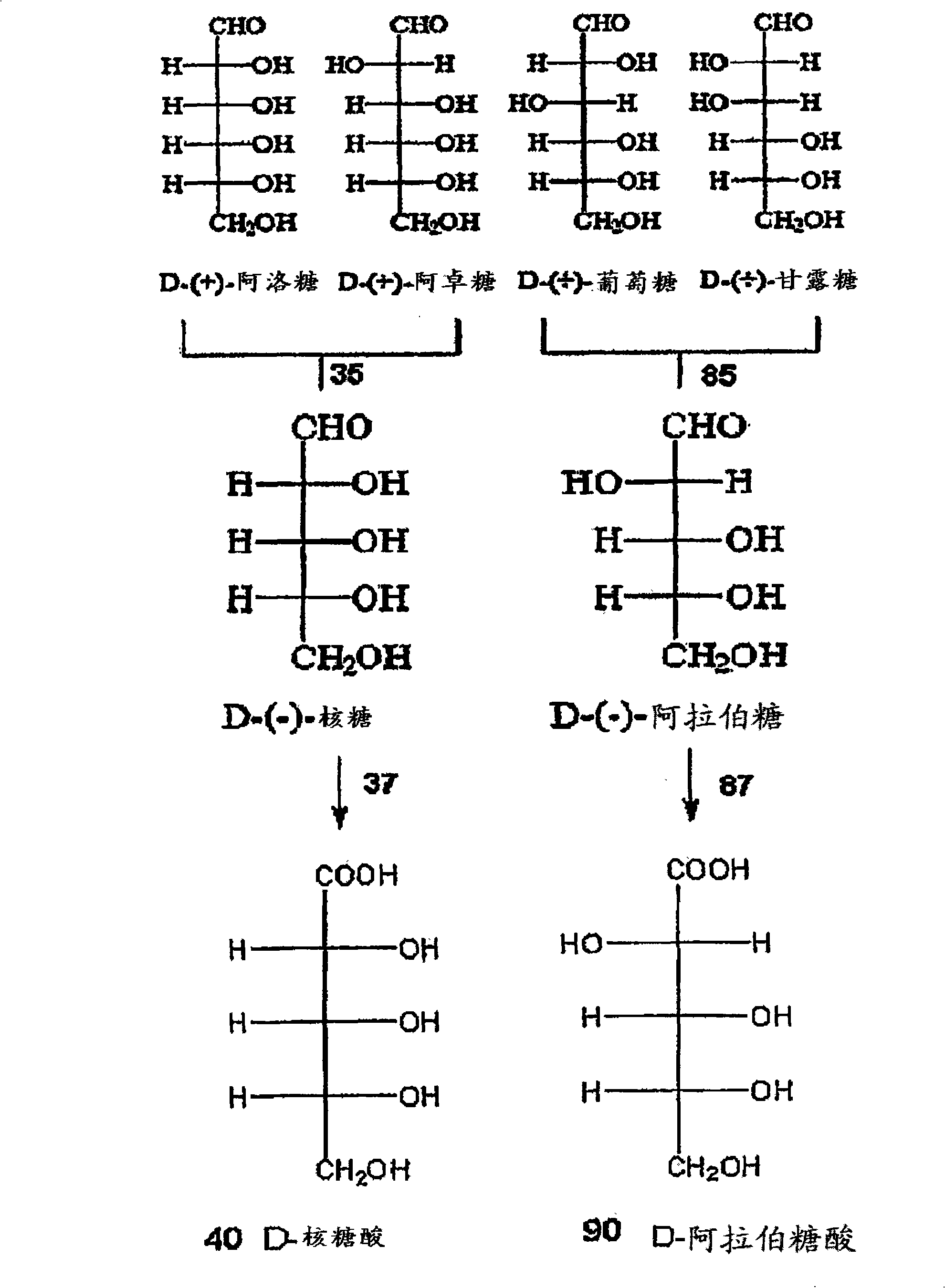

Method used

Image

Examples

Embodiment 1

[0068] Example 1: Electrolytic Decarboxylation of Ribose Acid

[0069] Sodium ribonate (15 mmol) was dissolved in 20 mL of water. Addition of cation exchange resin (Amberlite IRC747 H+ form) lowered the pH from 6.8 to 3.5 (or neutralized about 50% of the feedstock). The above solution was filtered to remove the cation resin, the ribose salt raw material was diluted to 30 mL, and 25 mL was transferred to a glass cell for electrolysis. The initial ribonate solution was analyzed by HPLC against standards and quantified at 9.54 millimolar (0.38M). Stir 25 mL of stock containing 9.54 mmol of ribonate in a glass cell while applying 0.5 A (100 mA / cm 2 ) constant current. The cell voltage averaged about 6.5 volts, and the pH of the substrate increased from 3.5 to 7.6 after a charge of 2 F / mole had passed. Samples were taken at 603, 1206 and 1809 coulombs. Samples containing erythritol product were reduced to erythritol using excess sodium borohydride, and HPLC-RI was used to ...

Embodiment 2

[0072] Example 2: Electrolytic Decarboxylation of Arabinonic Acid

[0073] Potassium arabinonate (15 mmol) was dissolved in 20 mL of water. Arabinonic acid was acidified to approximately 50% neutralization by adding cation exchange resin (Amberlite IRC747 H+ form) and lowering the pH from 8.4 to 3.5. The arabinonic acid salt was filtered to remove the resin, diluted to 30 mL, and transferred to a glass cell for electrolysis. Initial arabinonate was quantified by HPLC-RI relative to arabinonate standards and found to contain 9.2 millimolar (0.37M). There was a loss of 3.3 mmoles of arabinate to the cation exchange resin.

[0074] Stir 25 mL of stock containing 9.2 mmol arabinate in a glass cell while applying 0.5 amps (100 mA / cm 2 ) constant current. The cell voltage averaged about 5.5 volts, and the pH of the substrate increased from 3.5 to 7.7 after passing a 2F charge per mole of feedstock. Samples were taken at 603, 1206 and 1809 coulombs. Samples containing erythro...

Embodiment 2-5

[0081] Theoretical Examples 2-5: Oxidative decarboxylation and hydrogenation of glucose to arabitol

[0082] Elseviers et al. in U.S. Patent 5,831,078 filed July 23, 1997 and issued November 3, 1998 for the oxidative decarboxylation of glucose feedstock to arabinonate and the conversion of arabinonate to arabinitol Other suitable examples of are provided below as Theoretical Examples 2-5.

[0083] Theoretical Example 2: Oxidative Decarboxylation Using Oxygen at a Pressure of 2 Bars

[0084] Under stirring at 1000 rpm, the glucose solution (1.5 kg-10% w / w solution) feedstock was heated to 45° C. in a two-liter autoclave. The reactor containing the glucose solution was purged with oxygen twice for 0.5 min at a pressure of 1 bar. After purging, the oxygen pressure in the reactor was adjusted to 2 bar. The reaction was started by dosing potassium hydroxide solution (242 g - 50% w / w solution) to the glucose solution using a dosing burette at a dosing rate of 1.3 moles KOH / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com