Efficient shell and tube type condenser

A condenser and shell-and-tube technology, which is applied in the field of heat transfer equipment, can solve the problems of high heat transfer attenuation, poor heat transfer of heat transfer tubes, and reduced heat transfer efficiency of heat transfer tubes, and achieve the effect of improving heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

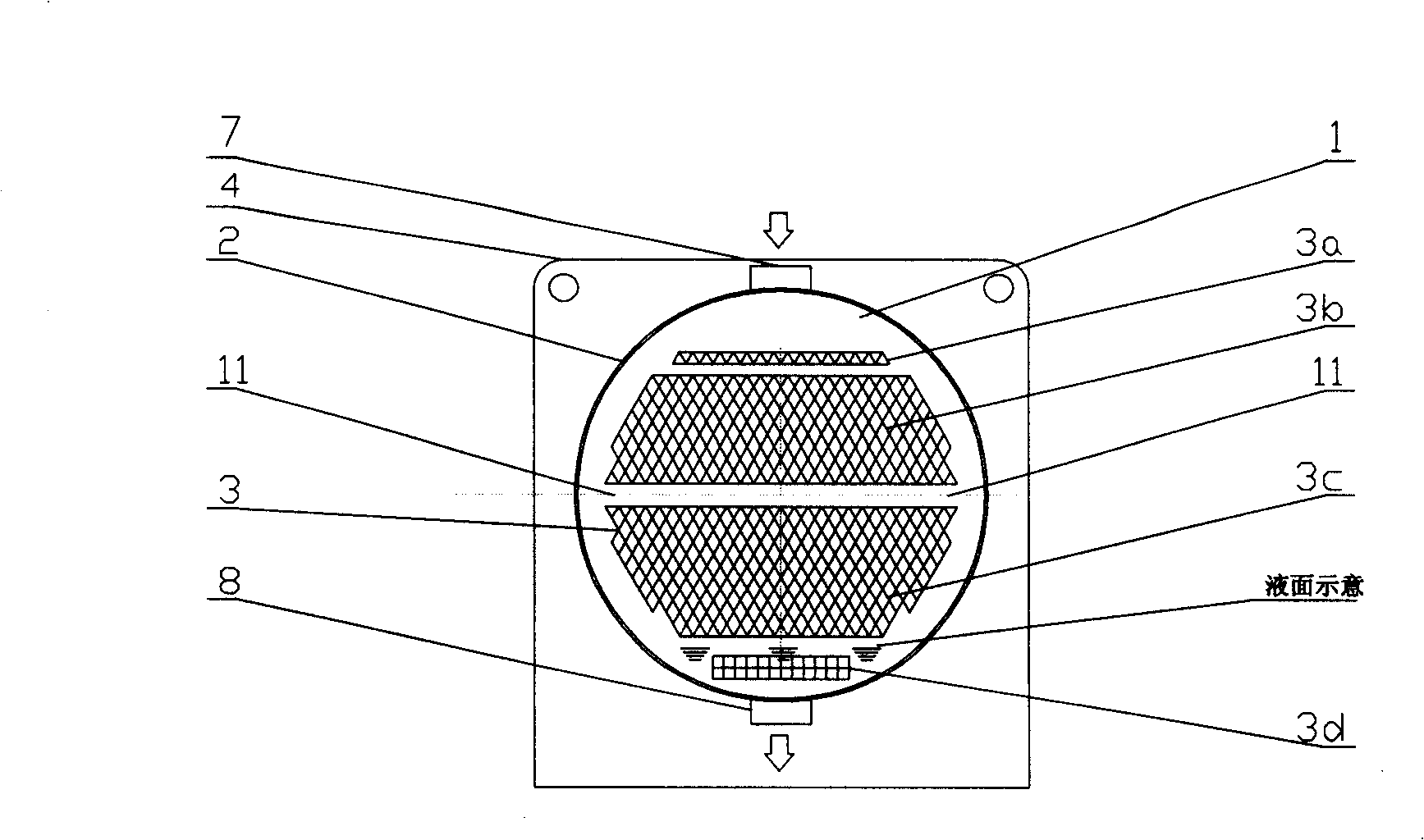

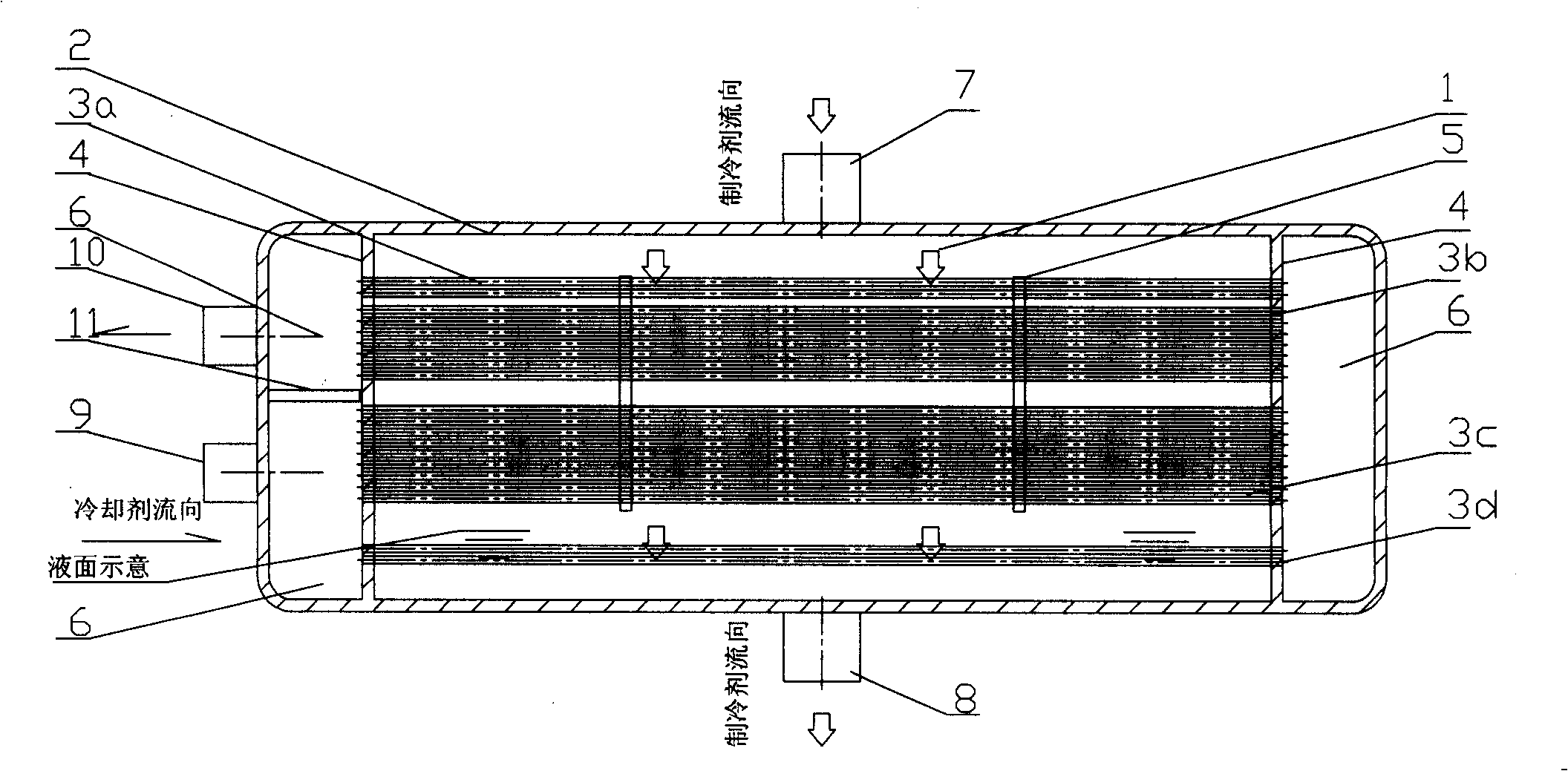

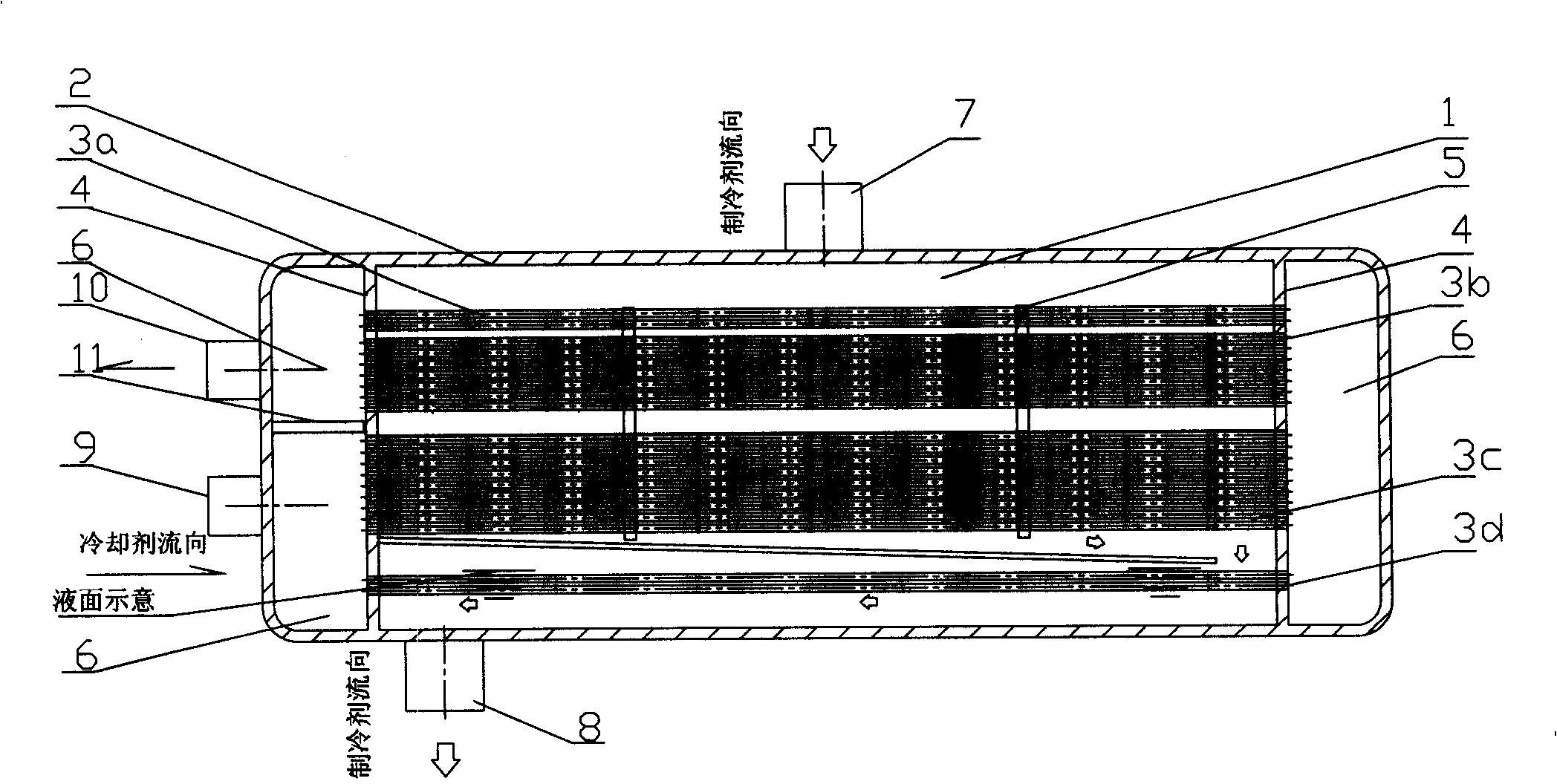

[0029] The conventional structure of shell and tube condenser is as follows: figure 1 , as shown in 2 and 3, usually the cooling liquid walks in the tubes, and in the shell, the superheated gas of the refrigerant enters from the upper interface 7, and when passing through the heat transfer tube bundle 3, because the temperature of the cooling liquid in the tube is low, the gas first passes through the tube bundle 3a and is Cool to near saturation, and then further condense into liquid through tube bundle 3b. In the tube bundles 3b and 3c, due to gravity, the condensate gradually drips from the tubes, and because the tube spacing of the condenser is usually small, the condensate is easy to accumulate on the tubes laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com