Self-acting valve of pressure cooker

A technology of automatic valves and pressure cookers, applied in pressure cookers, etc., can solve the problems of increased product failure probability, complicated pressure valve structure, and increased production costs, and achieve the effects of safe and reliable failure rates, convenient daily cleaning, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific example

[0025] The present invention will be specifically and further described below in conjunction with the accompanying drawings.

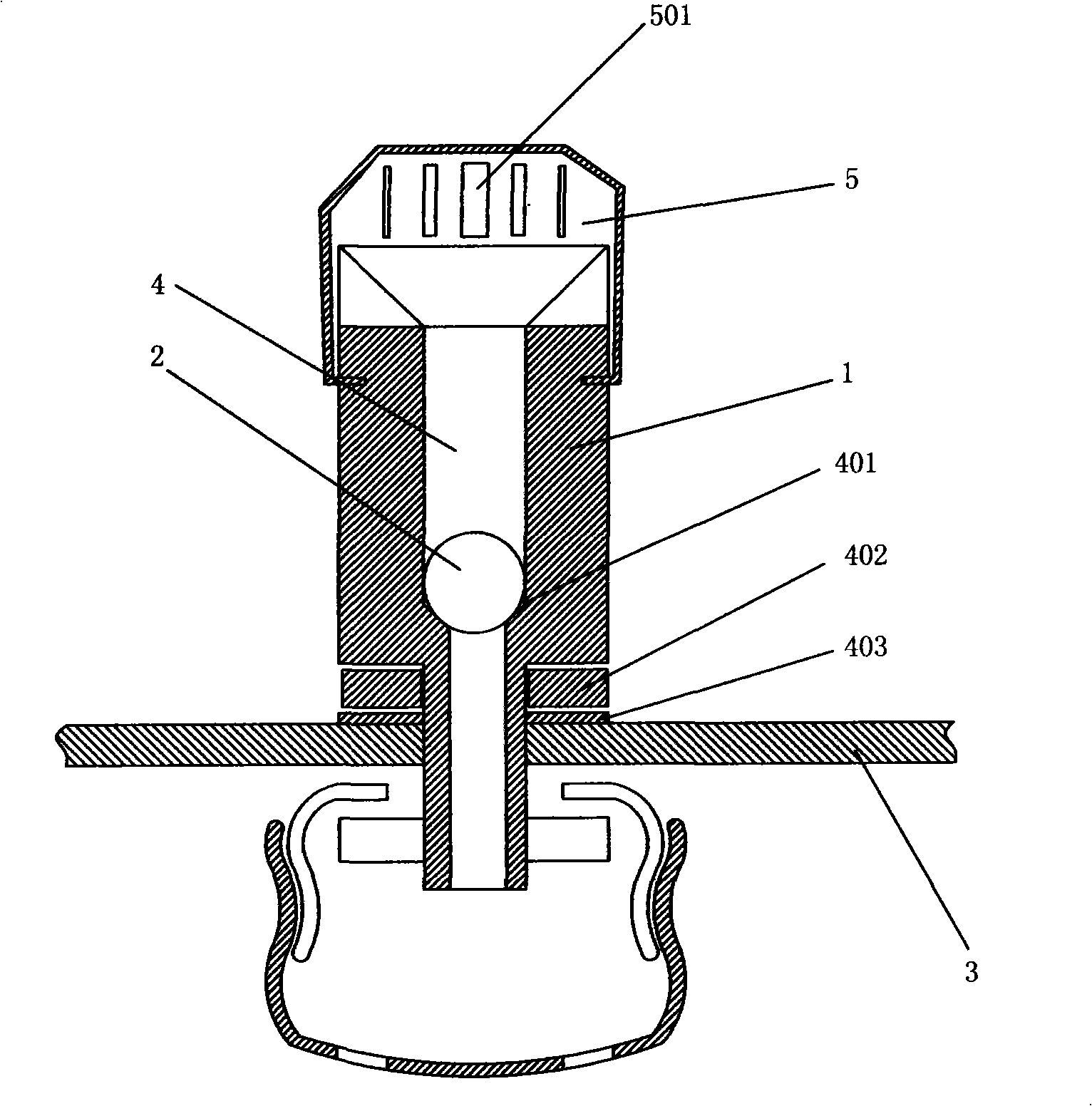

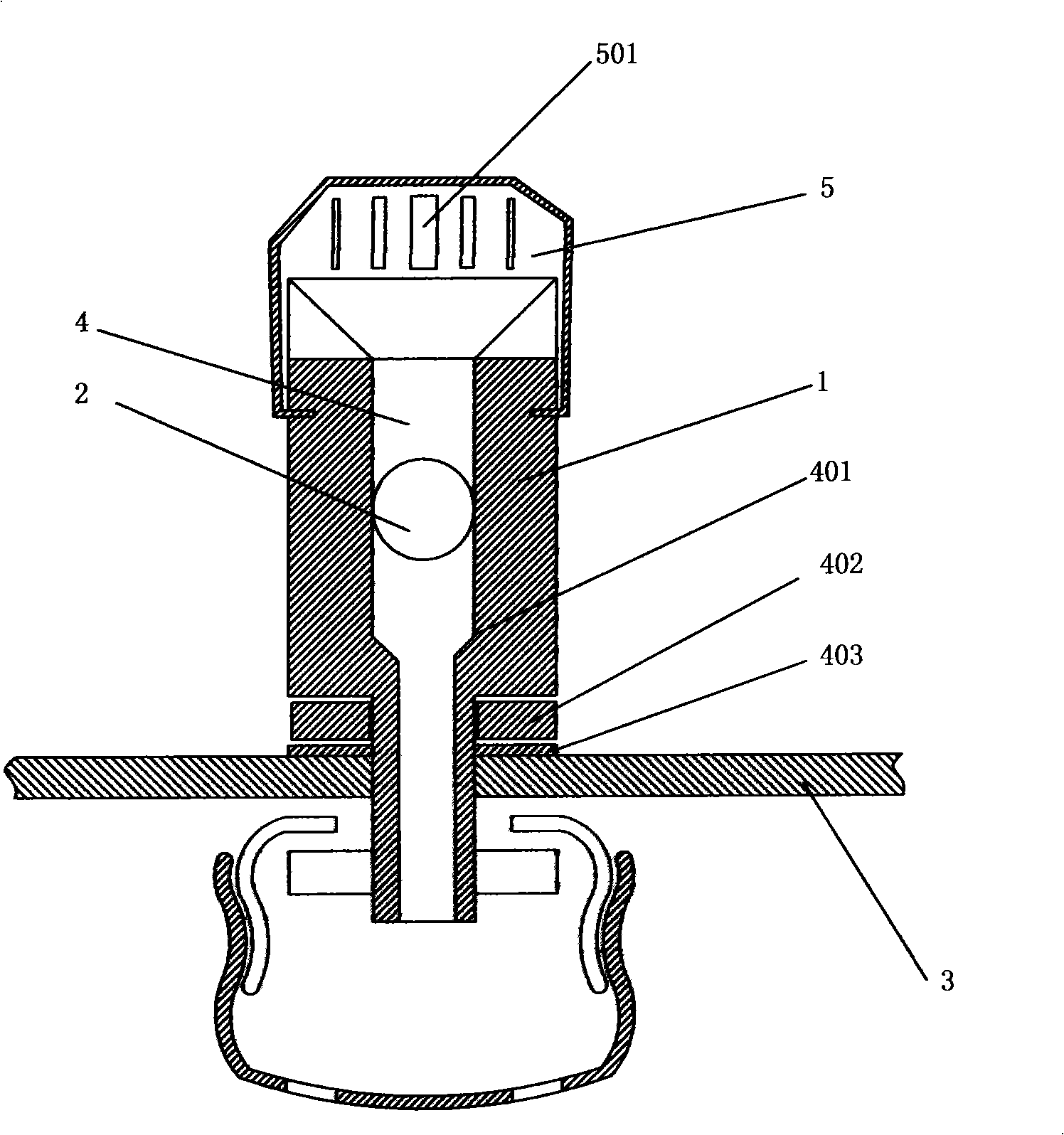

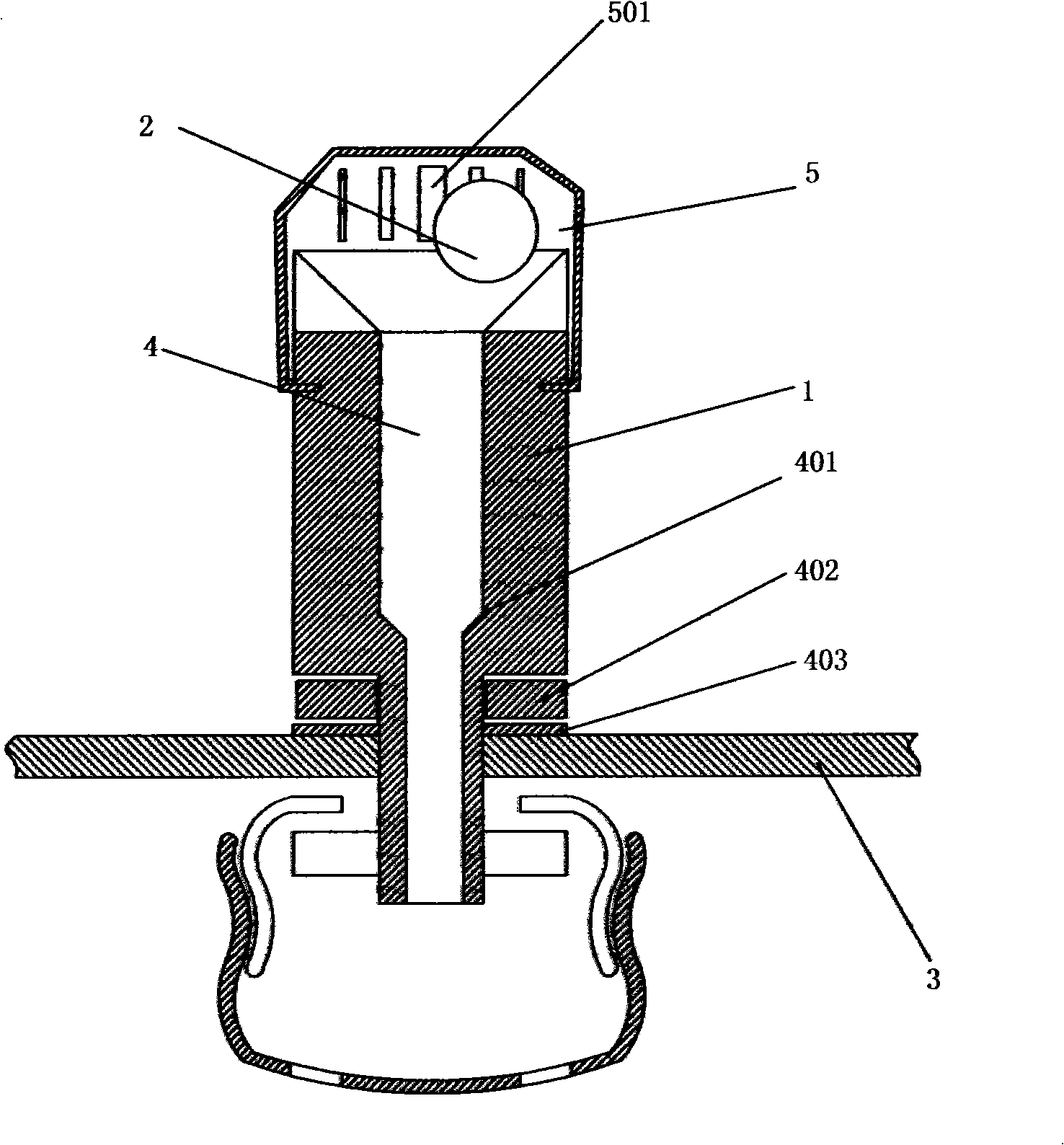

[0026] Such as figure 1 As shown, it consists of a valve seat 1 and a valve core 2. The valve seat 1 is provided with an exhaust passage 4 connecting the inside and outside of the pot. The valve core 2 is located in the exhaust passage 4, and the exhaust passage 4 is provided with a step 401. , the diameter of the upper section of the step 401 matches the size of the spool 2, the spool 2 is located on the port of the step 401, and closes its port, the spool 2 is made of a magnetic material, and the lower end of the step 401 is provided with a magnetic block 402, Attracted with the spool 2, the spool 2 can move up and down in the exhaust passage 4, and when there is no pressure in the pot, the spool 2 stops on the step 401 and seals the passage.

[0027] The valve seat 1 is made of non-magnetic material, and the lower end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com