A new type of tailrace tunnel ventilation hole structure

A technology of tailrace tunnels and ventilation holes, which is applied in water conservancy projects, hydroelectric power generation, hydroelectric power stations, etc., can solve the problem that the minimum negative pressure and the maximum positive pressure cannot be well balanced, and achieve a remarkable effect and relieve the impact pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

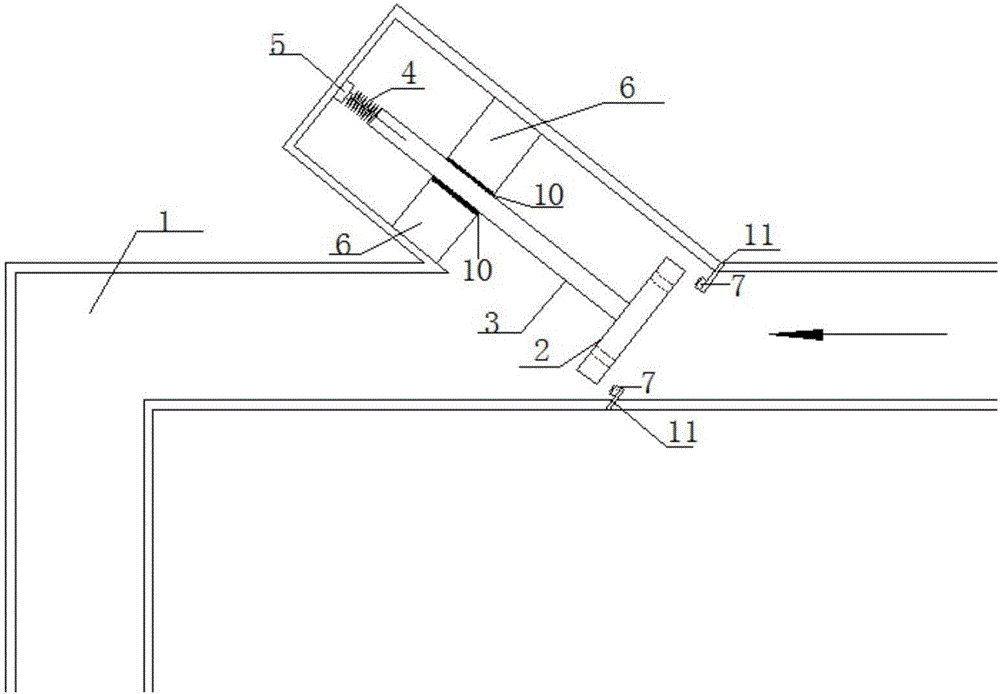

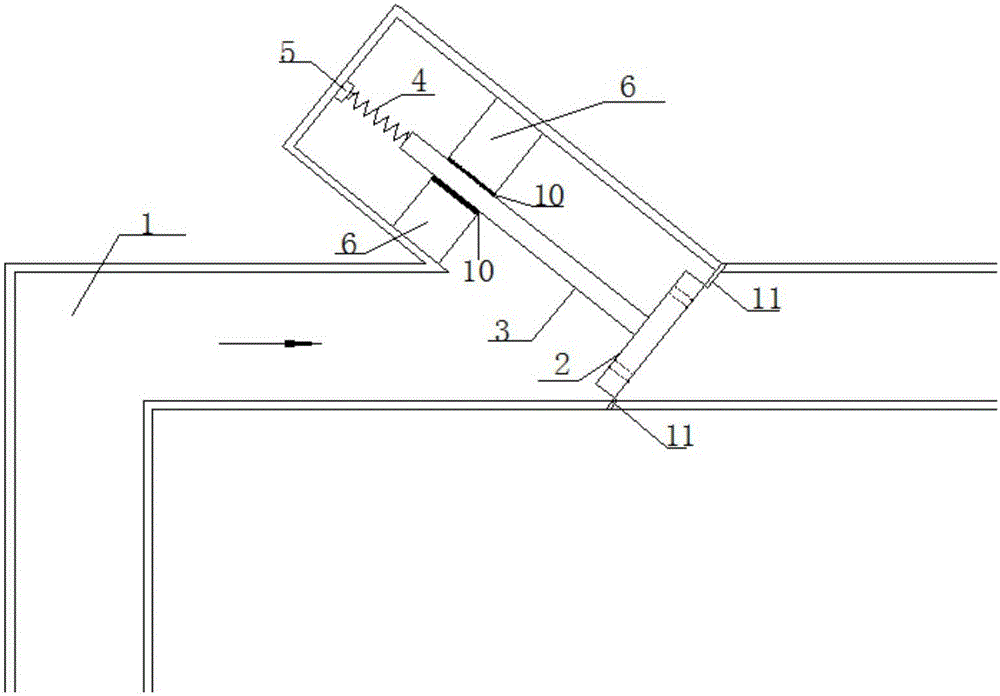

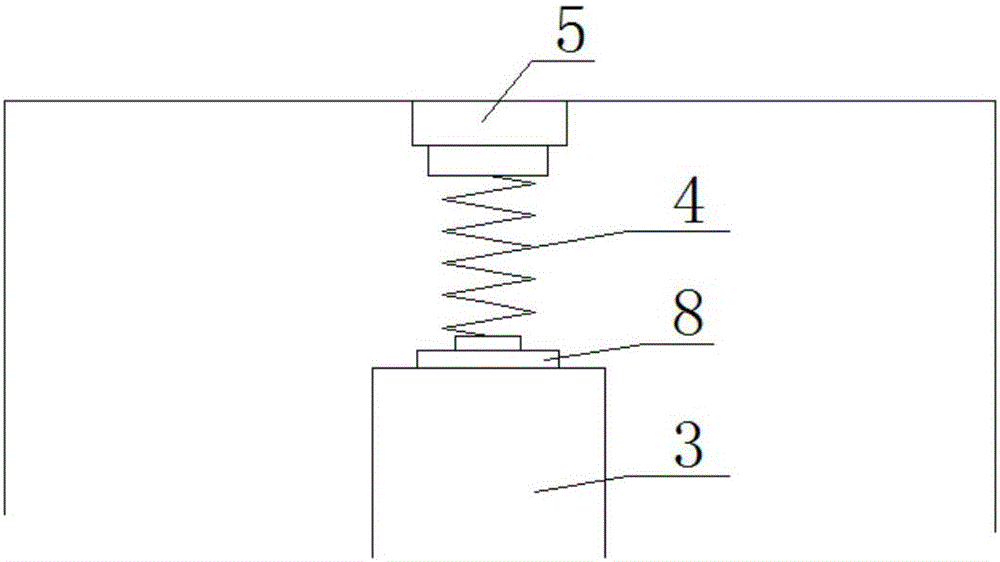

[0033] The novel tailrace tunnel ventilation orifice structure of this embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, when the movable baffle 2 is closed, the air flow can only pass through the reserved round hole 9 in the movable baffle 2, the movable connecting rod 3 is fixed with the movable baffle 2, and the annular anti-slip block body 6 is used to fix the movable connecting rod 3. direction. A movable baffle 2 is set at the ventilation hole 1. When the movable baffle 2 is opened, the movable connecting rod 3 slips sideways. A lubricating device 10 is arranged between the annular anti-slip block body 6 and the movable connecting rod 3. The spring buffer device 5 is used to protect The movable connecting rod 3, when the movable baffle 2 is pushed up by the air flow of the intake air, the movable connecting rod 3 moves accordingly, compressing the spring 4, at this time, the ventilation hole is full-area air intake; when the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com