Automatic glue dropping system with synchronous material feed and method thereof

A technology for automatic dispensing and dispensing, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of expensive mechanical arm devices, increase manufacturing costs, and consume operating time, so as to increase manufacturing costs and reduce processing. time, the effect of speeding up the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

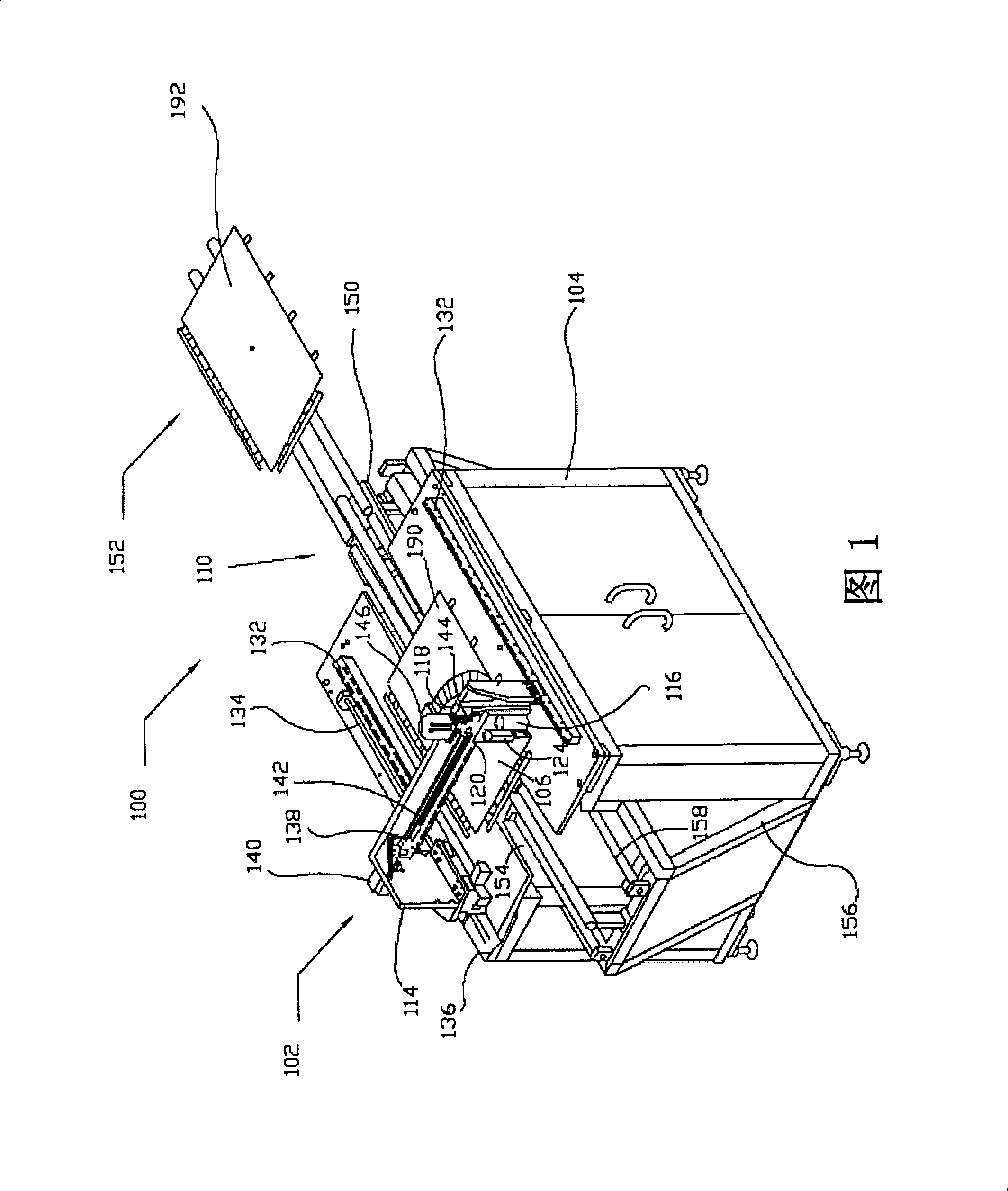

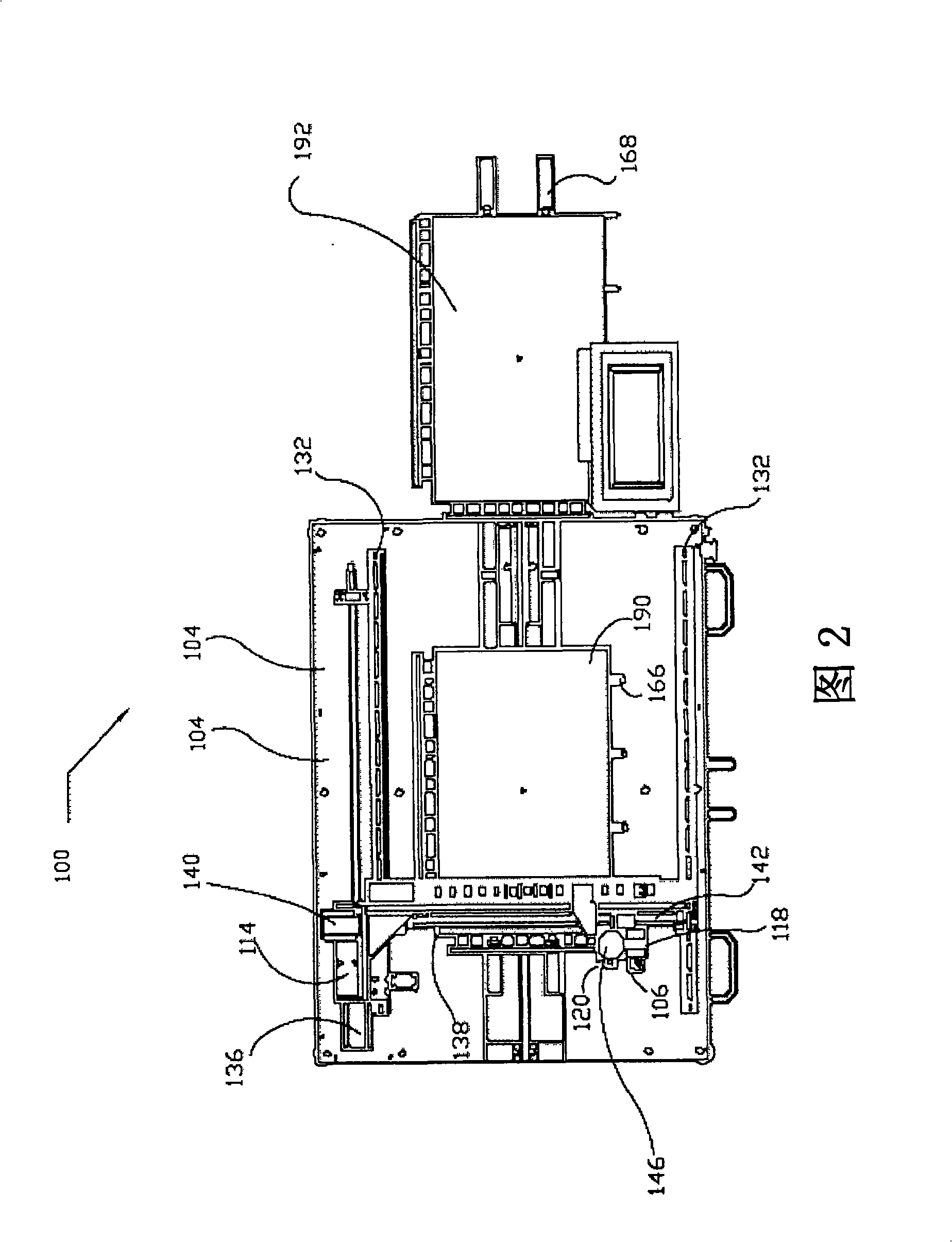

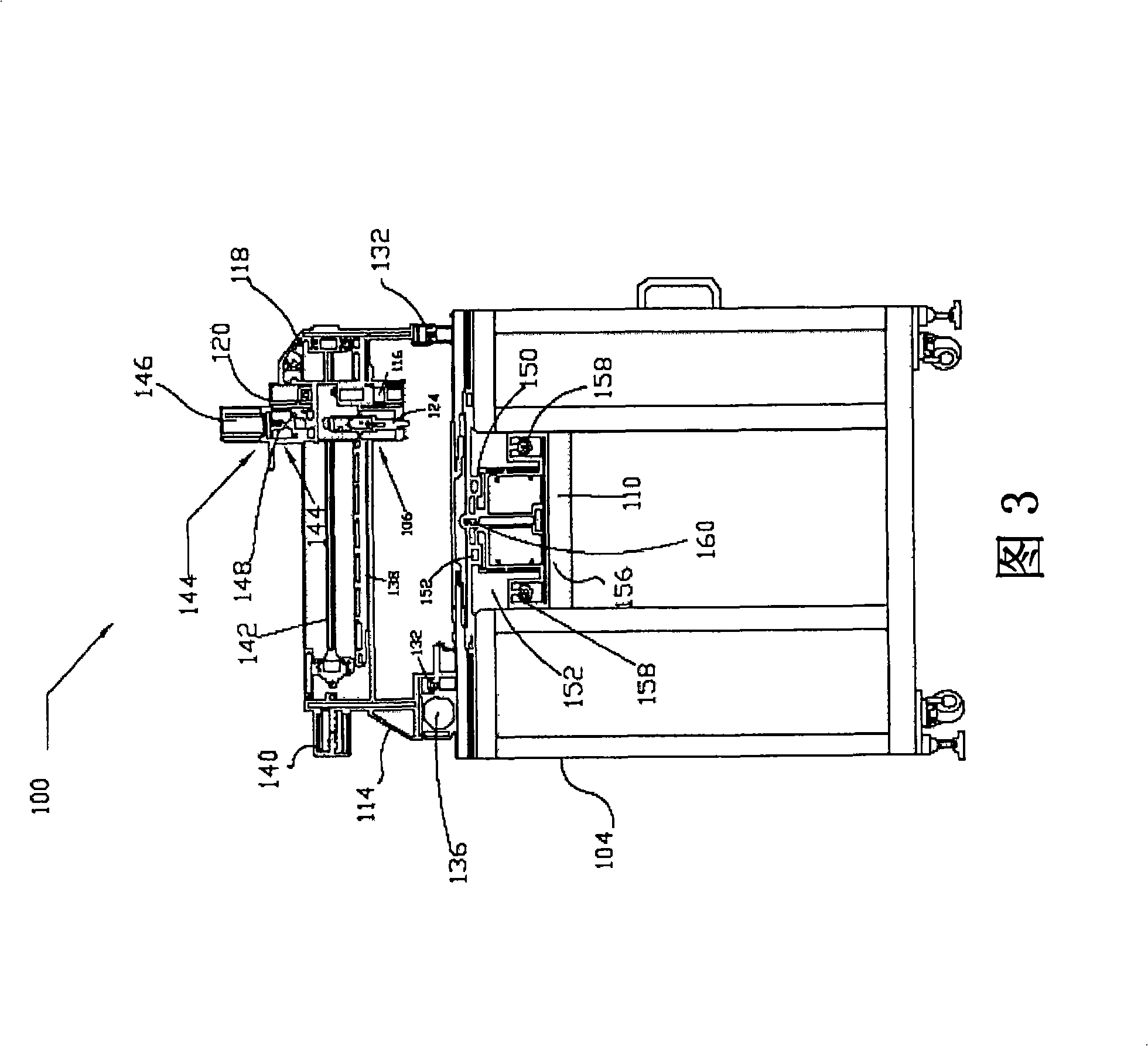

[0056] For a more complete understanding of the present invention and its advantages, detailed description will be given below with reference to the accompanying drawings, wherein like numerals represent like components. It should be understood that all the specific embodiments in the present invention are for illustrative purposes only, so except for the specific embodiments herein, the present invention can also be widely applied in other embodiments, and the present invention is not limited to any implementation For example, the scope of the appended claims and their equivalents should be determined.

[0057] Throughout this patent specification, "a specific embodiment" means to describe a specific feature, structure or characteristic related to a specific embodiment, and in the present invention, the number of the specific embodiment is at least one. Therefore, the appearance of "in a specific embodiment" in this specification does not necessarily mean that the same embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com