Stop dog of clamper

A technology of block and fixture, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of short service life of the crimping device, affecting work efficiency, scratches on the PCB board, etc., to improve the service life, high practicability, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

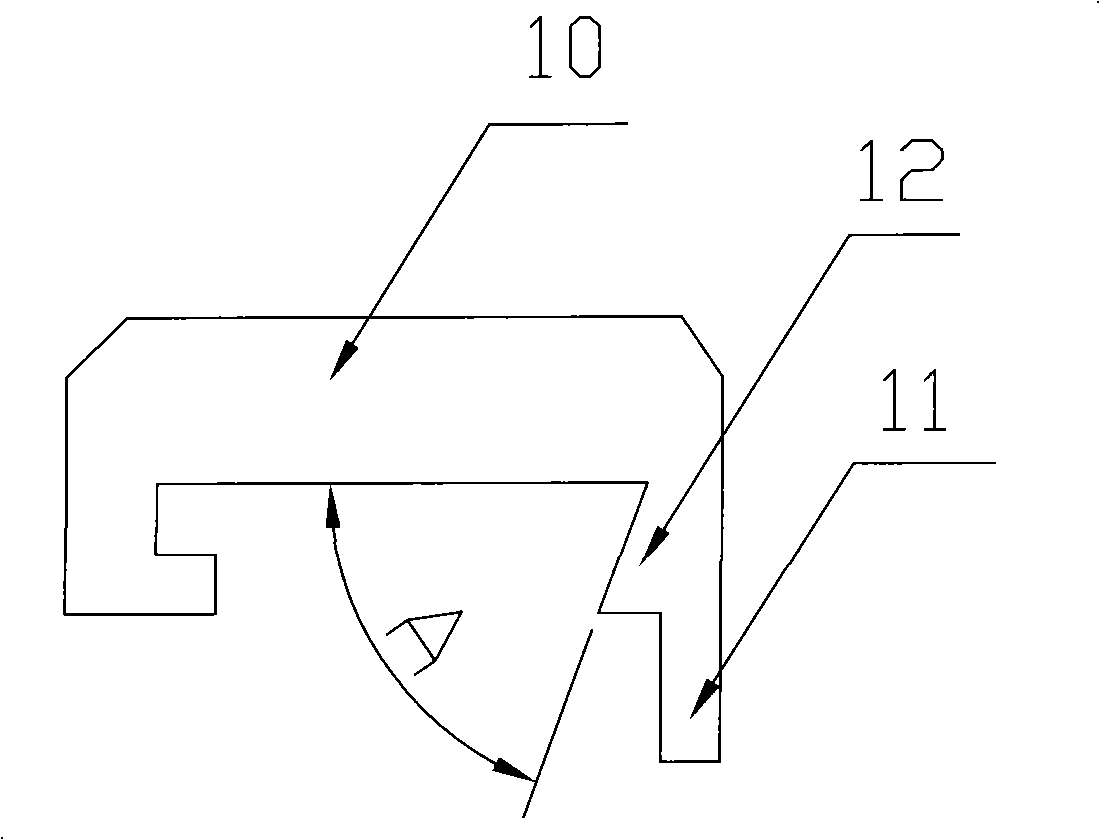

[0017] Such as figure 1 The shown clamp block includes a block body 10, an extension block 11 is provided on one side of the block body 10, and a raised triangular block 12 is arranged inside the extended block 11, and the raised triangular block The connection angle A between one side of 12 and the lower side of the block body 10 is 70 degrees.

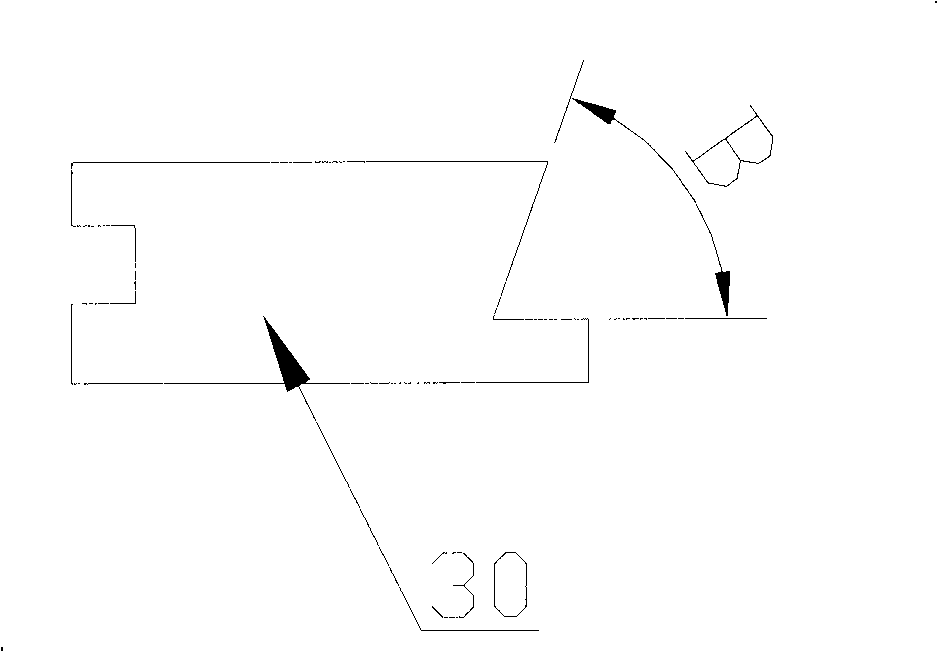

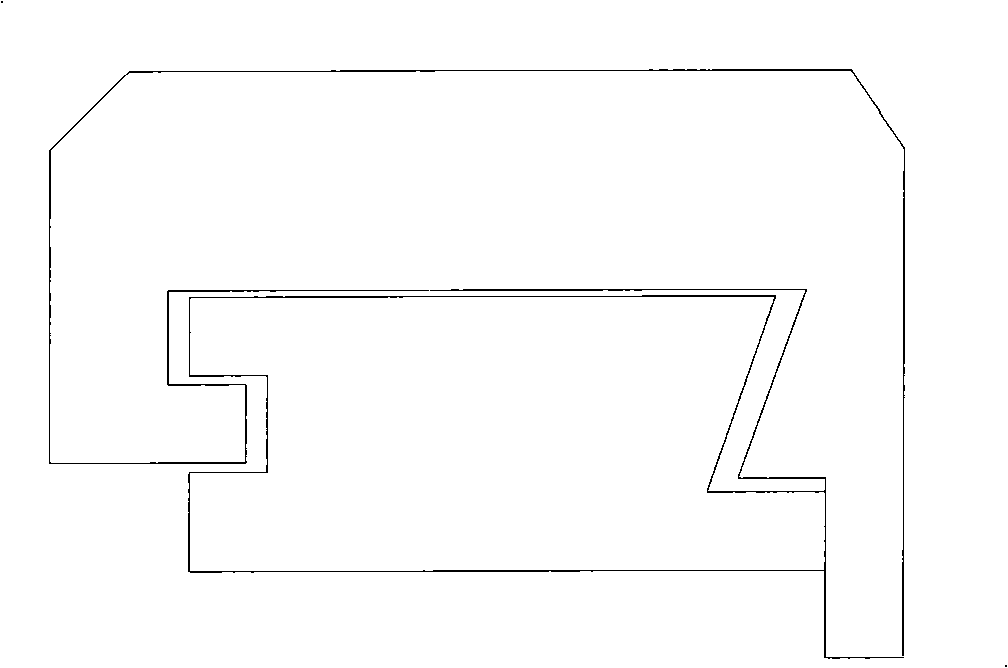

[0018] Such as image 3 , Figure 5 As shown, the block body 10 is slidably connected to the bar-shaped loading platform 30, and is fixed on the bar-shaped loading platform by screws, and the block body 10 can freely move left and right on the bar-shaped loading platform 30 when the connection is loosened.

[0019] Such as Figure 4 As shown, the block body 10 is connected on the bar-shaped loading platform 30, and the PCB board 20 is fixed in the middle by the two front and rear bar-shaped loading platforms 30 and the left and right two blocks 10 installed on the front and rear bar-shaped loading platform 30.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap