Preparation method iron based SmFeAsO1-xFx superconducting wire

A smfeaso1-xfx, superconducting wire technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of poor material performance, low preparation success rate, small sealing and restraint effects, etc. problems, to achieve the effect of convenient operation, high preparation success rate, and increase of critical current density

Inactive Publication Date: 2010-12-01

SOUTHWEST JIAOTONG UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Press the raw materials into sheets and wrap them with tantalum sheets, seal them in a vacuum quartz tube for high-temperature sintering, and wrap them with tantalum sheets to have little sealing and restraining effect on the raw materials, making the prepared superconducting materials loose and poor in material performance

At the same time, during the sintering process, the volatilized fluorine will corrode the quartz tube and cause the quartz tube to break, making the success rate of sample preparation low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

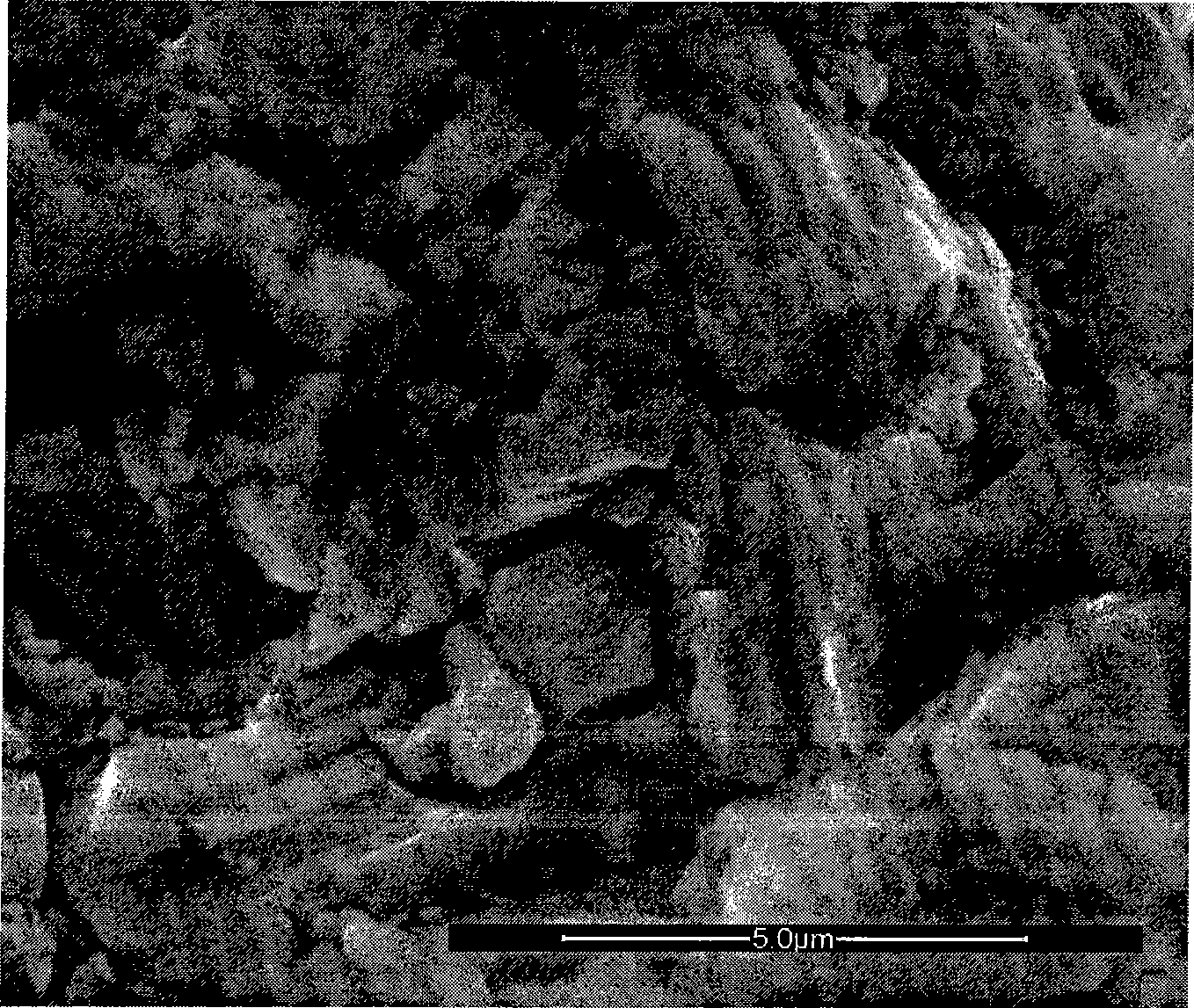

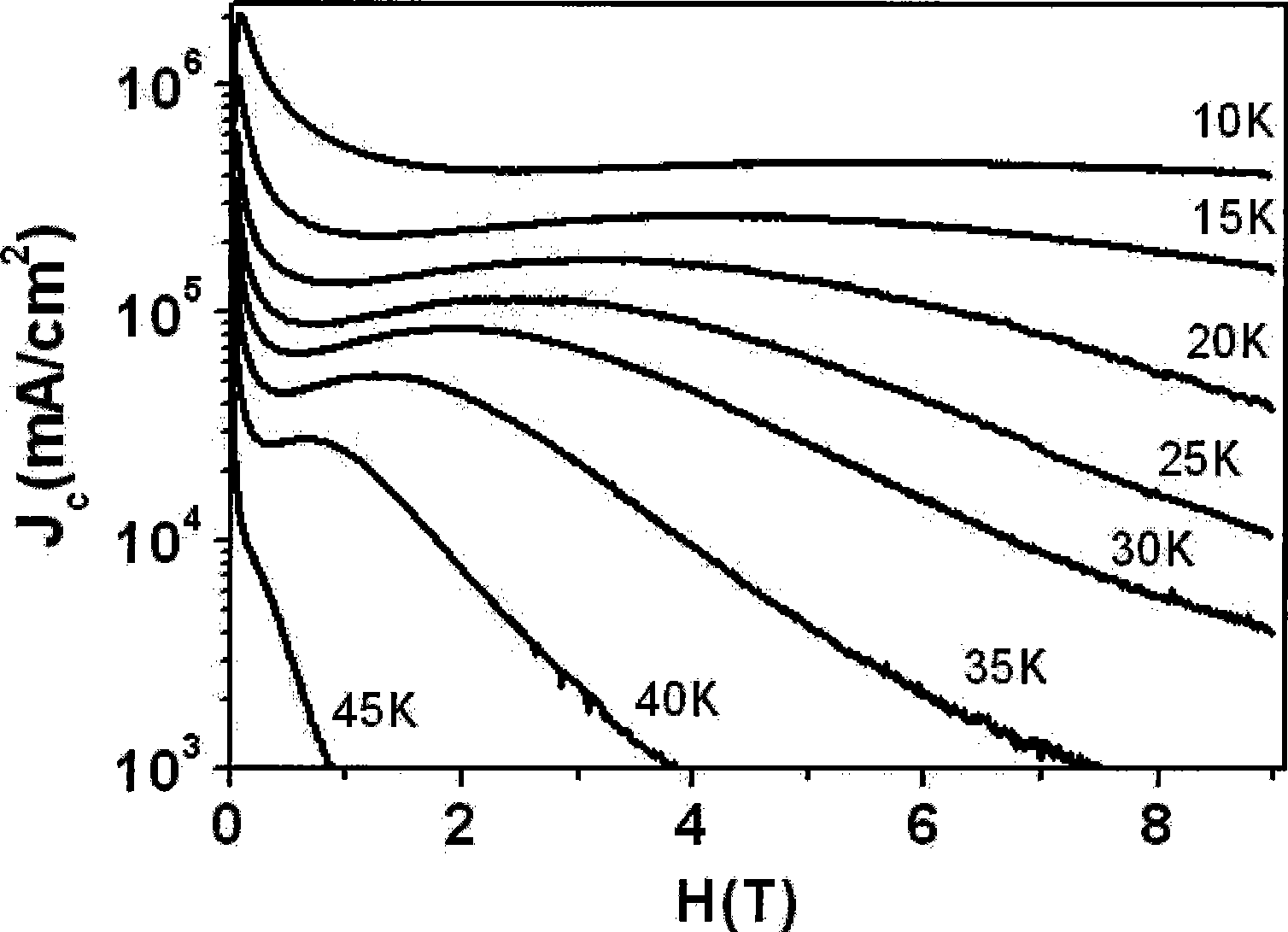

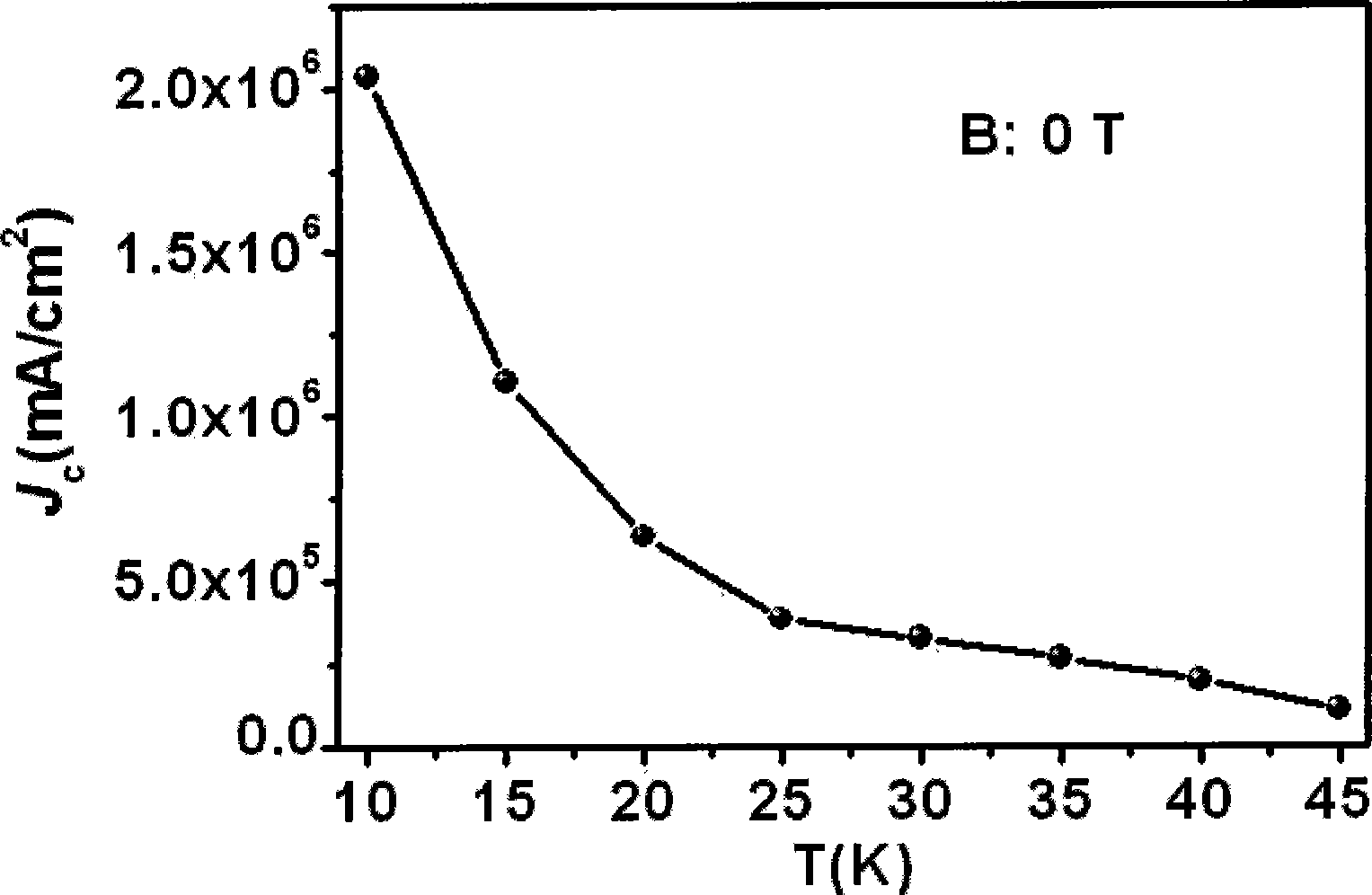

The invention provides a preparation method of an iron-based SmFeAsO<1-x>Fx superconducting wire, comprising the steps as follows: a: material preparation: the material is prepared according to the stoichiometry of the iron-based superconducting material SmFeAsO<1-x>Fx (wherein, x is not more than 0.35 and not less than 0.15, the raw materials such as SmAs, Fe, Fe2O3 and FeF3 are weighed, grinded, uniformly mixed, arranged into a Tantalum pipe, fully fixed and compacted; the two ends of the Tantalum pipe are sealed; b: wire preparation: the Tantalum pipe is sheathed into a copper pipe and rotatablely forged; subsequently, the wire with the diameter of 1.8-2.2mm is formed by pulling and drawing; c: burning: the wire is arranged in a quartz pipe and sealed in vacuum and then put into a sintering furnace; under the protection of inert gas, the temperature of the wire is increased to 1150-1170 DEG C at the speed of 100-150 DEG C / hour, the temperature is kept for 36-50 hours and the wire is cooled with the furnace. The method of the invention has the advantages of simple technology and facilitating industrial production, and the compactness, high purification, stable superconducting performance, high superconducting conversion temperature and high critical magnetic field of the prepared iron-based SmFeAsO<1-x>Fx superconducting wire.

Description

A kind of preparation method of iron-based SmFeAsO1-xFx superconducting wire technical field The invention relates to a method for preparing an iron-based SmFeAsO1-xFx superconducting material, in particular to a method for preparing an iron-based SmFeAsO1-xFx superconducting wire. Background technique In early 2008, Japanese and Chinese scientists successively reported the discovery of a new class of high-temperature superconducting materials—iron-based superconducting materials, which aroused widespread concern in the scientific community. Japanese scientists first discovered that La[O1-xFx]FeAs compounds have superconducting properties at a critical temperature of 26 Kelvin (Journal of the American Chemical Society Vol. 130, p. 3296). Subsequently, the research team led by Chen Xianhui from the University of Science and Technology of China discovered that the SmFeAsO0.85F0.15 compound also becomes a superconductor at a critical temperature of 43 Kelvin ("Nature" volume ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B12/00H01B13/00

CPCY02E40/64Y02E40/60

Inventor 陈永亮崔雅静赵勇张勇程翠华

Owner SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com