Process for manufacturing popcorn machine with wide heat-preserving range

A manufacturing process and popcorn machine technology, which is applied in the field of food processing machinery and equipment manufacturing, can solve the problems of limited heat preservation range of heat preservation lamps, etc., and achieve the effect of good display effect, reasonable process and wide heat preservation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

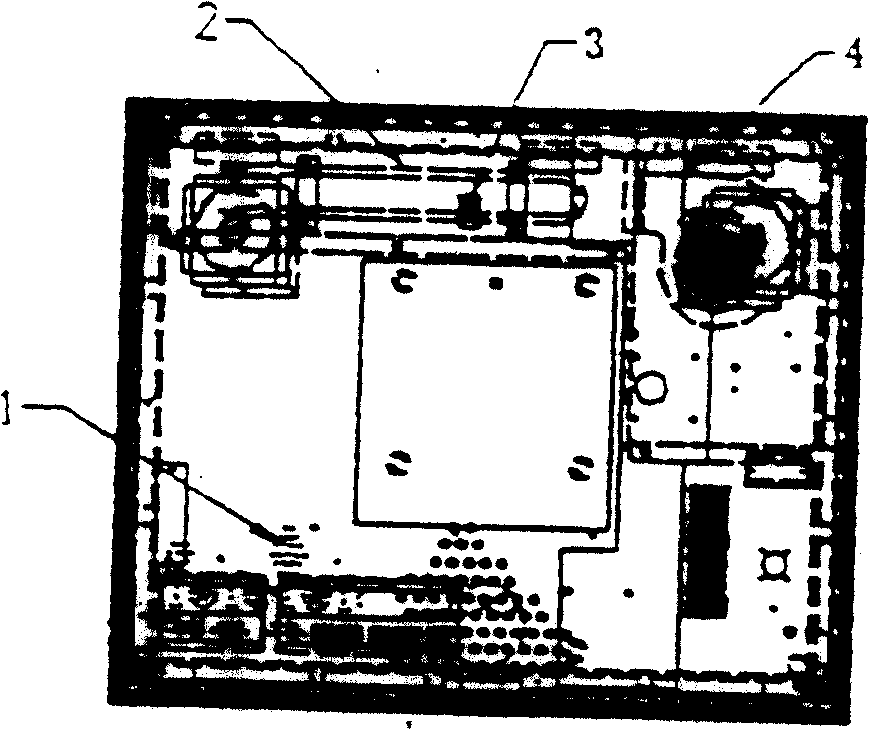

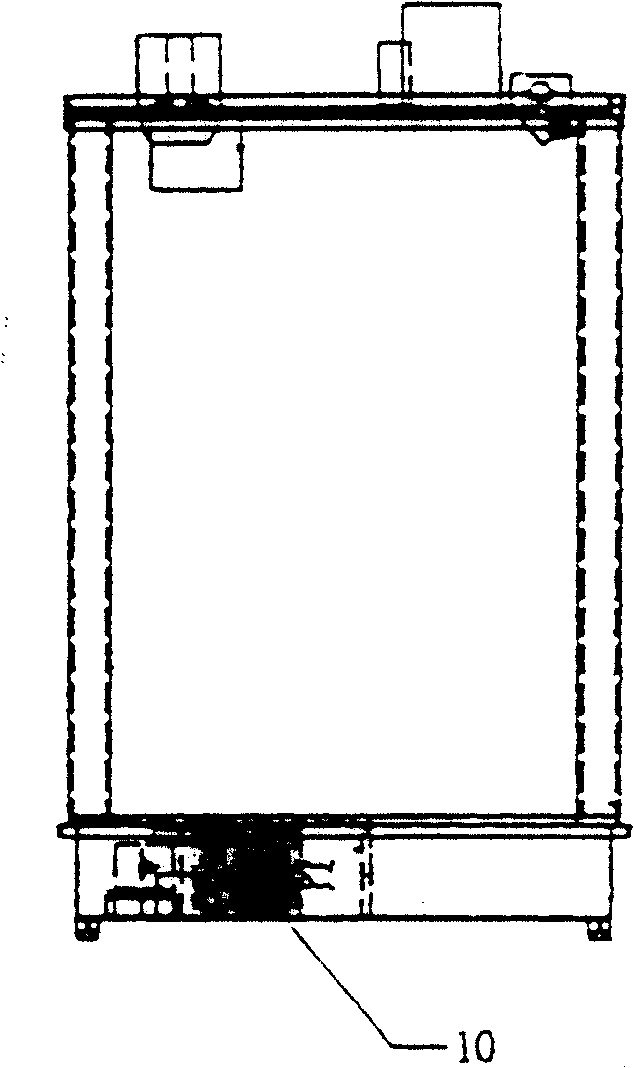

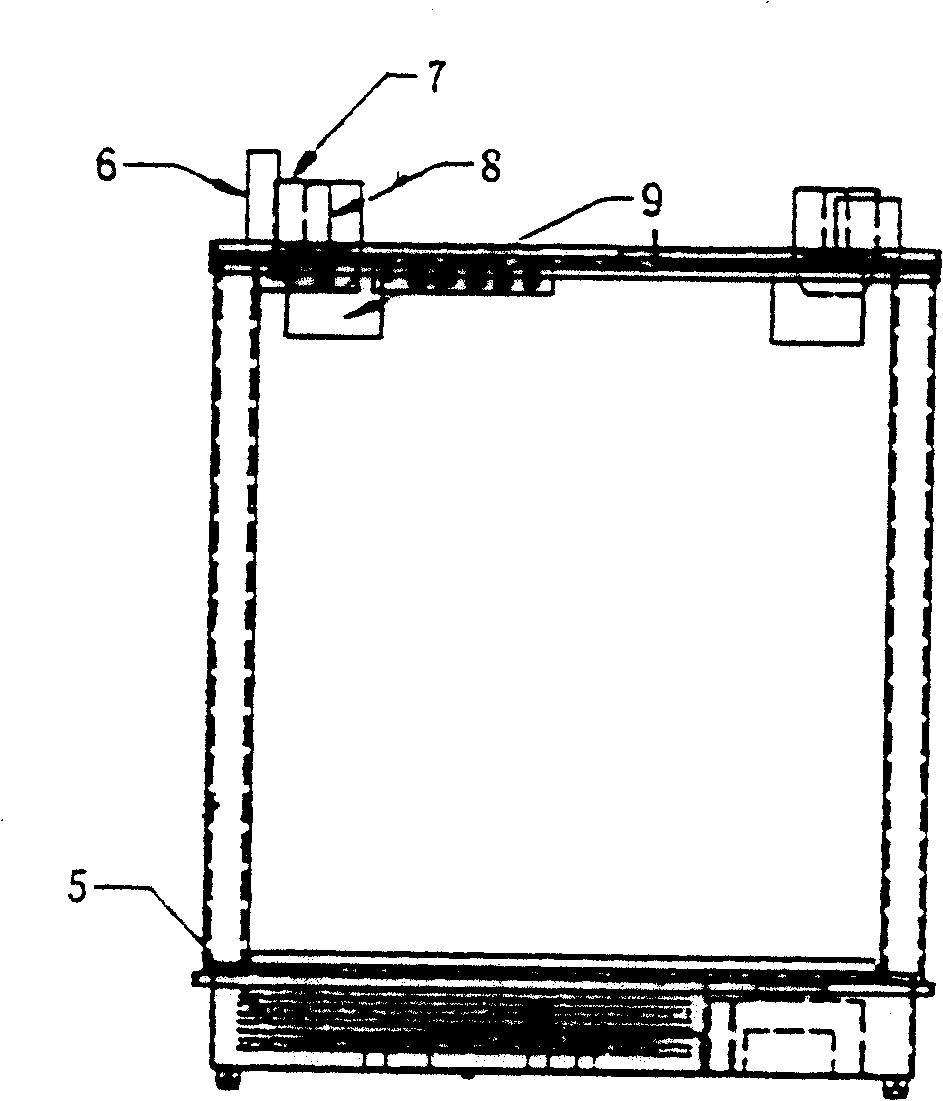

[0010] A manufacturing process of a popcorn machine with a wide range of heat preservation mainly includes the following steps: two heat preservation lamps are provided on the lampshade. Below in conjunction with accompanying drawing, the structure of the wide popcorn machine that the present invention manufactures is described in further detail. see figure 1 , the shelf 1 rests on the bottom frame, the heat preservation electric heating tube 2 and the limit protection 3 are fixed on the bottom plate through the bracket, and the heat preservation fan 4 is fixed on the bottom plate with screws, see figure 2 , image 3 , the heat dissipation fan 6 and the lampshade 7 are fixed on the installation frame with screws, the heat preservation lamp 8 is installed on the lampshade 7 through threads, the heat preservation electric heating pipe cover 5 and the heat preservation fan cover 10 are fixed on the bottom plate with screws, and the lamp baffle 9 is fixed with screws Fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com