Novel inclined pin ejecting structure

A new type of oblique tip technology, applied in the field of oblique tip ejection structure, can solve problems such as inapplicability, and achieve the effects of simple structure, good promotion value, and reduced extension length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to have a further understanding of the structure, composition and technical characteristics of the present invention, the following will be described in detail in conjunction with the accompanying drawings:

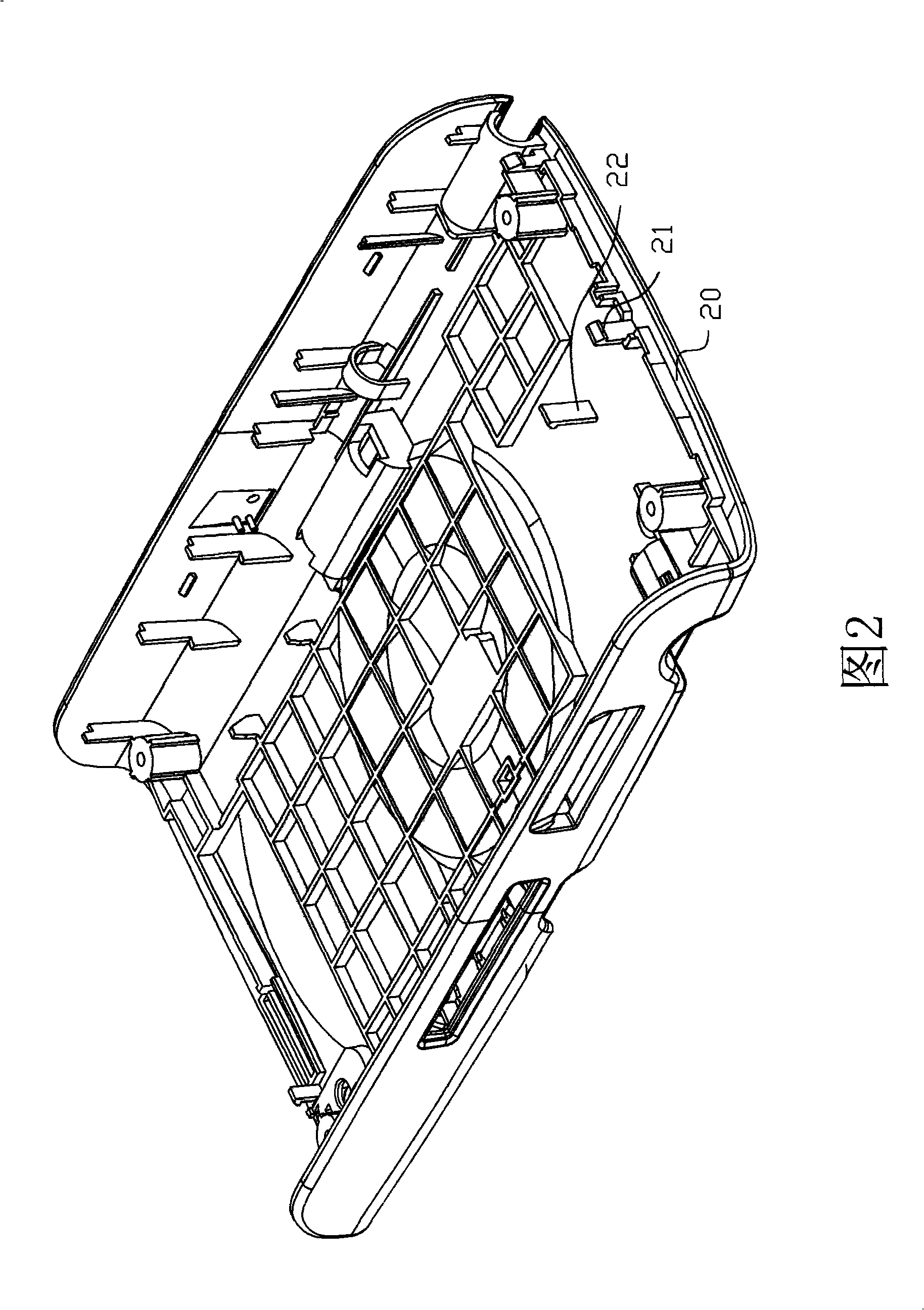

[0013] The present invention is designed for products that cannot be ejected from the surface with two or more barbs that are relatively close to each other in the prior art. As shown in Figure 2, the surface opposite to the male die core (not shown) There are two barbs 21 and 22 on the side, and the distance between the barb 21 and the barb 22 is relatively close.

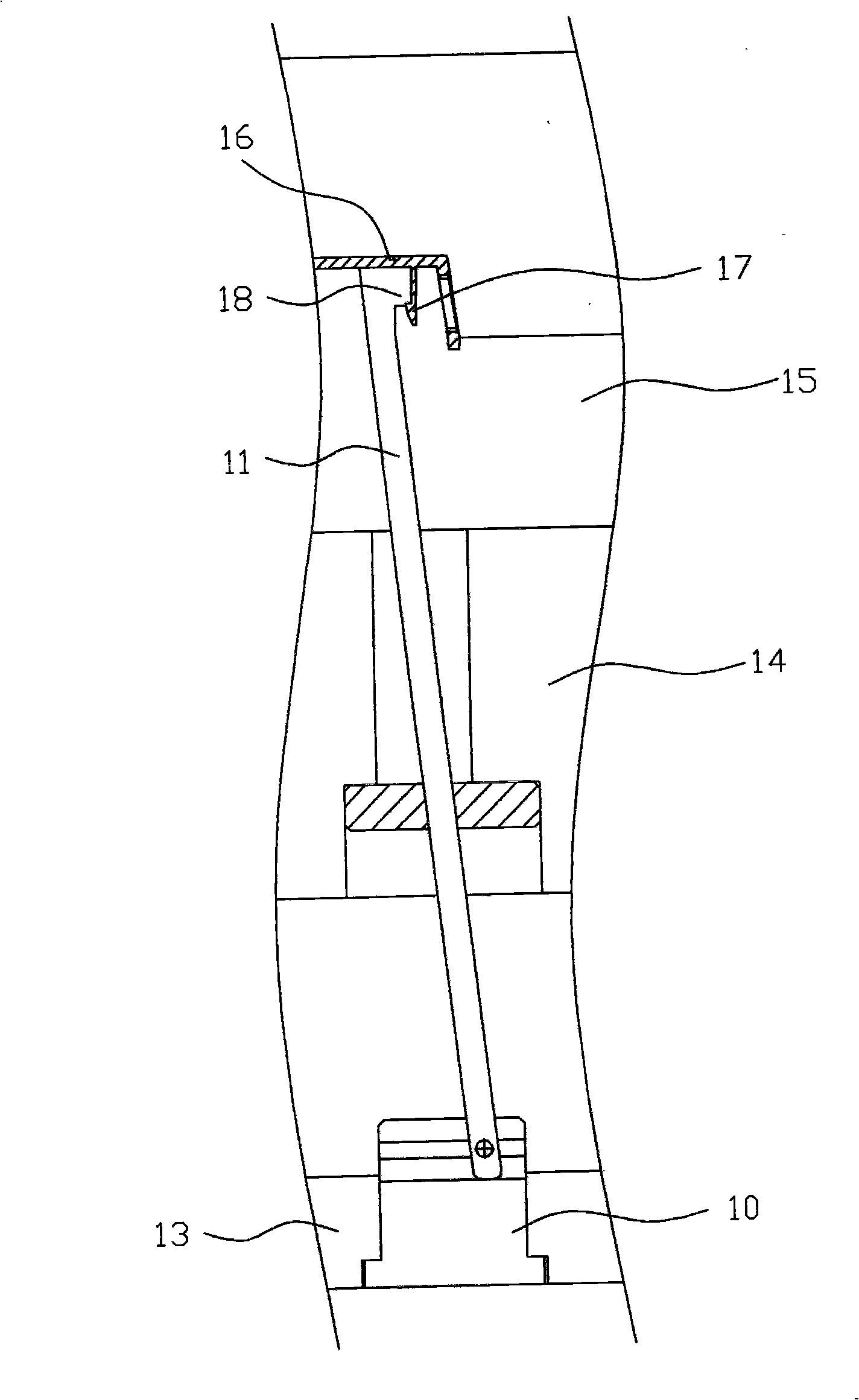

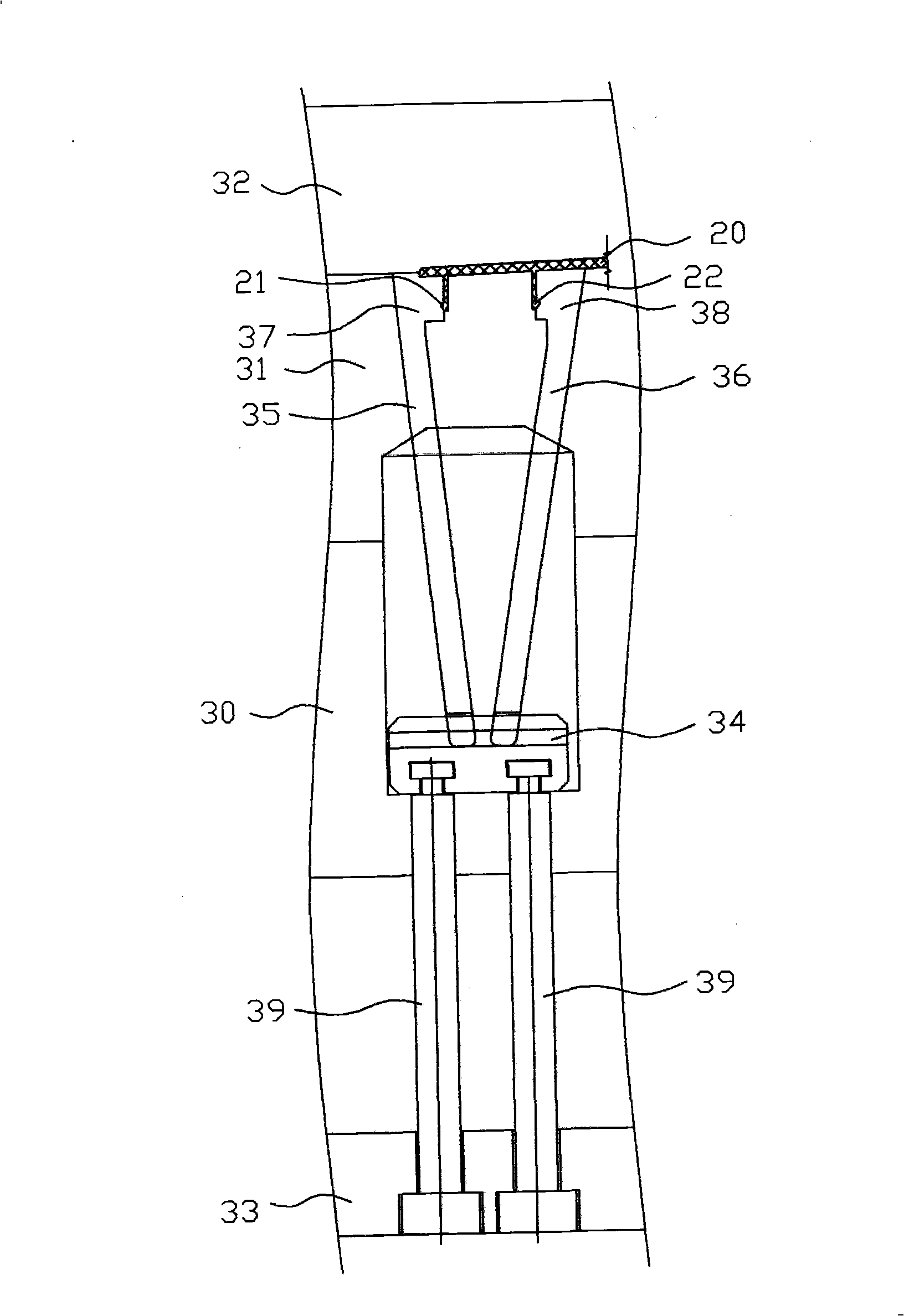

[0014] Please refer to Figure 2 and image 3 shown, where image 3 It is a schematic diagram of the ejection structure of the new oblique tip; the ejection structure of the oblique tip is suitable for a mold structure, the mold includes a male template 30, the male template 30 is provided with a male mold core 31, and an ejector is provided below the male template 30. plate 33, the mold also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com