Siding rail assembly and operating method thereof

A technology of slide rail assembly and operation method, used in furniture parts, home appliances, drawers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

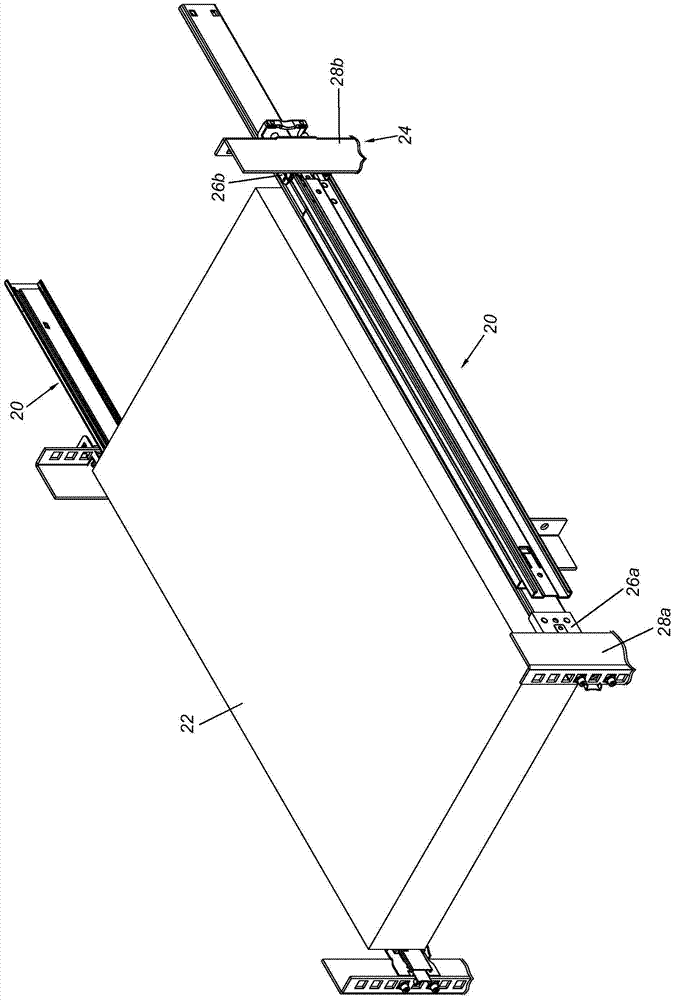

[0041] figure 1 A pair of slide rail assemblies 20 showing an embodiment of the present invention can be used to mount a load 22 to a rack 24 . Specifically, each slide rail assembly 20 can be mounted on a first column 28a and a second column 28b of the frame 24 by means of a first bracket 26a and a second bracket 26b. Since this part is a technical category that can be understood by those who are familiar with the field, for the sake of brevity, details are not repeated here.

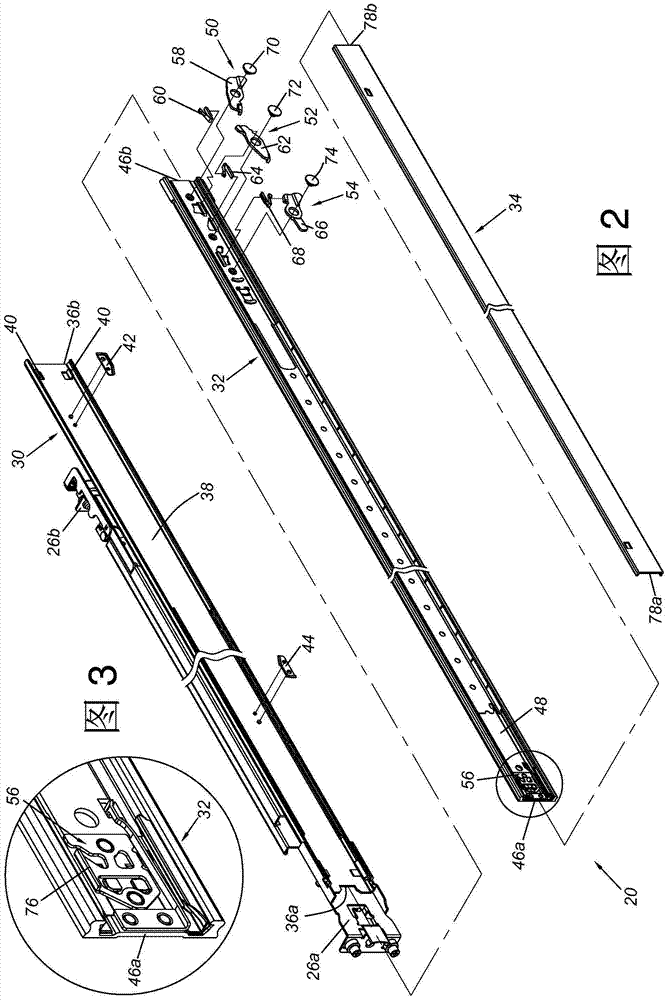

[0042] As shown in FIG. 2 , the slide rail assembly 20 includes a first rail 30 , a second rail 32 and a third rail 34 . The first rail 30 is provided with the above-mentioned first bracket 26a and second bracket 26b. The first rail 30 has a front end 36a, a rear end 36b, and a first channel 38 located between the front end 36a and the rear end 36b. Preferably, the first rail 30 has at least one contact portion 40, such as two protrusions, located adjacent to the rear end 36b. In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com