Sedimentation parabolic type multi-point discharge belt conveyor

A conveyor and material belt technology, applied in the field of settling parabolic multi-point discharge belt conveyor, can solve the problems of wear of flapper valve and other components, flapper valve mixing accident, material damage, etc., to avoid mixing materials , The effect of unloading completely and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

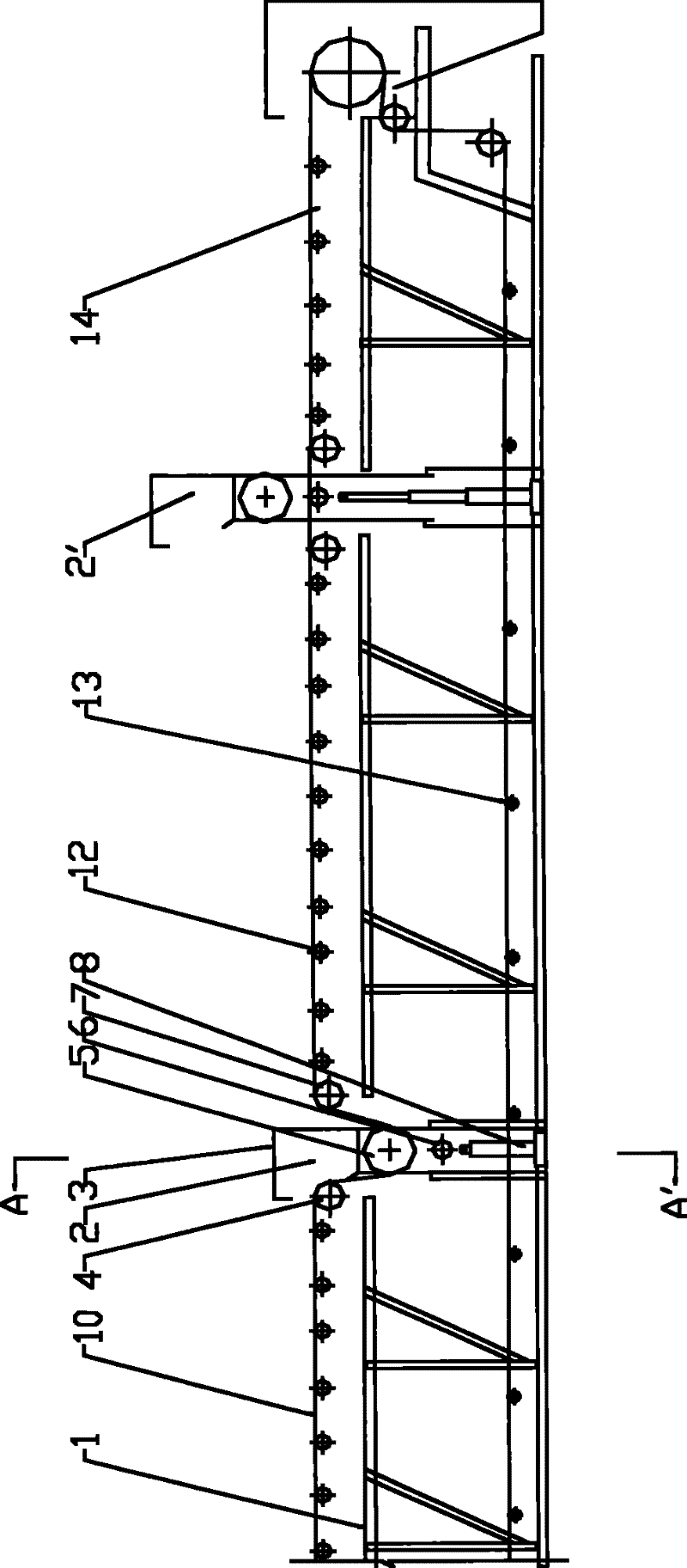

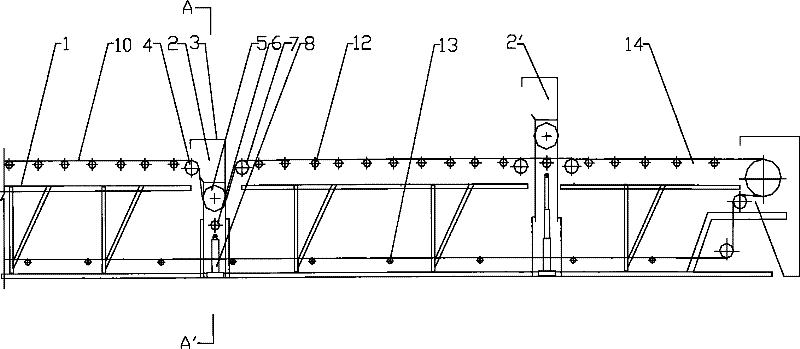

[0022] Such as figure 1 As shown, the transport section 1 and the settling discharge section 2 are installed relatively independently, so that the settling parabolic guide trough 3 of the settling discharge section 2 can rise and fall freely without being affected by the transport section 1; the head of the transport section 1 is equipped with a parabolic redirecting roller 4 , the parabolic redirection drum 4 faces the sedimentation parabola guide groove 3 on the upper part of the sedimentation parabola section 2 forward.

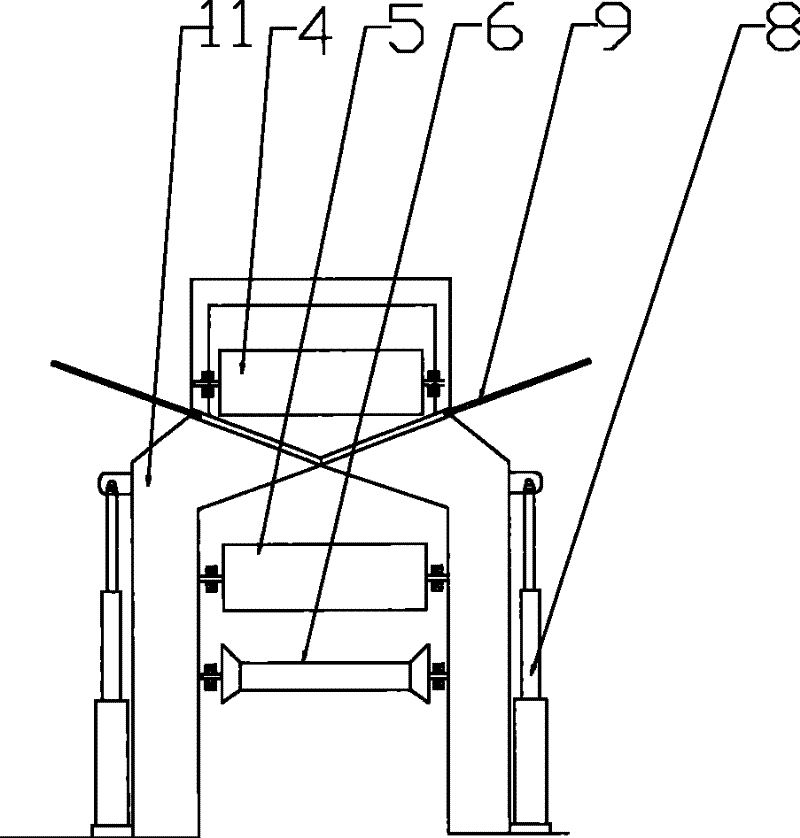

[0023] The settling parabolic section 2 is composed of a settling parabolic guide trough 3, and the two sides of the settling parabolic guide trough 3 are respectively equipped with a feeding chute 11, and the upper ends of the two feeding chute 11 are equipped with a two-way gate valve 9; Settling reversing drum 5 is installed in the middle, and settling belt lower roller 6 is installed at the bottom; lifting mechanism 8 is installed on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com